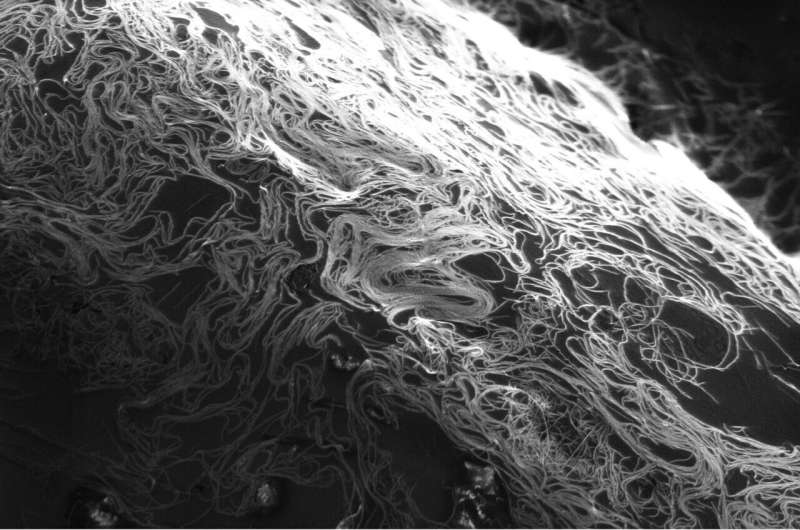

A special sauce can be used to realize the full potential of carbon nanotubes.

Rice University scientists have come up with just the sauce, an acid-based solvent that simplifies carbon nanotube processing in a way that is easier to scale up for industrial applications.

Matteo Pasquali's lab at Rice discovered a unique combination of acids that help separate nanotubes in a solution and turn them into films, fibers or other materials with excellent electrical and mechanical properties.

The solvent is compatible with conventional manufacturing processes according to the study co-led by Robert Headrick and Steven Williams. It should be able to find a place in the production of advanced materials.

Rice's A.J. Hartsook Professor and a professor of chemical said that it's probably not a good idea to increase the mining of copper and aluminum and nickel. He is the director of the Rice-based Carbon Hub, which promotes the development of advanced carbon materials.

He said that there is a giant opportunity to use hydrocarbons as our resources.

He said that carbon is plentiful, we control the supply chains, and we know how to get it out in a responsible way.

A better way to process carbon is needed. The solvent is made from methanesulfonic, p-toluenesulfonic, and oleum acids that are less corrosive than those currently used to process nanotubes in a solution. Before they can be extrude through a needle or other device where shear forces help turn them into familiar fibers or sheets, they need to be separated.

Oleum and chlorosulfonic acids are corrosive and have been used to dissolve nanotubes. The team combined oleum with two weaker acids to create a process that can be used for manufacturing nanotubes products.

Headrick said that the oleum surrounds each individual nanotube and makes them repel each other.

The milder acids further separate the nanotubes. They found that pToS is useful for 3D printing applications because it allows solutions to be processed at a moderate temperature and then solidified, and that it is best for fiber spinning and roll-to-roll film production.

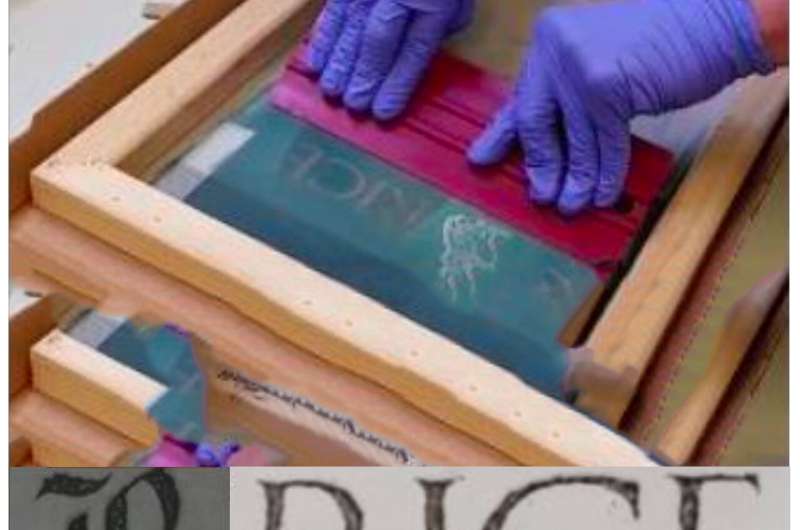

3D printing carbon nanotubes and silk screen printing patterns onto a variety of surfaces, including glass, are what the researchers used to make things in both modern and traditional ways.

It was surprising how well the solutions worked, Headrick said.

The solution of oleum is less aggressive to other materials once it isDiluted with the other acids.

Headrick said that the acids they are using are so gentle that they can be used with common plastic.

He said that carbon nanotubes are important for integrating them into other devices and for depositing them as one step in a device-manufacturing process.

They reported that the less-corrosive solutions were easier to clean up after production. The environmental impact and processing costs of pToS can be lowered after they are recycled.

Williams said the next step is to fine-tune the solvent for applications, and to determine how factors like size affect the process.

The paper was co-authored by alumni Lauren Taylor and graduate students Oliver Dewey and Cedric Ginestra of Rice, as well as graduate students Crystal Owens and A. John Hart at the Massachusetts Institute of Technology.

More information: Robert J. Headrick et al, Versatile acid solvents for pristine carbon nanotube assembly, Science Advances (2022). DOI: 10.1126/sciadv.abm3285. www.science.org/doi/10.1126/sciadv.abm3285 Journal information: Science Advances Citation: New solvent simplifies industrial 3D, roll-to-roll carbon nanotube printing (2022, April 27) retrieved 27 April 2022 from https://phys.org/news/2022-04-solvent-industrial-3d-roll-to-roll-carbon.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.