The sustainable society of the future will rely on the efficient conversion of plant biomass into renewable fuels and chemicals. The efficiency of the cell factories is affected by compounds that are released when thebiomass is degraded into sugars. How can these processes be improved? The results of a research project at the University have been published in a journal.

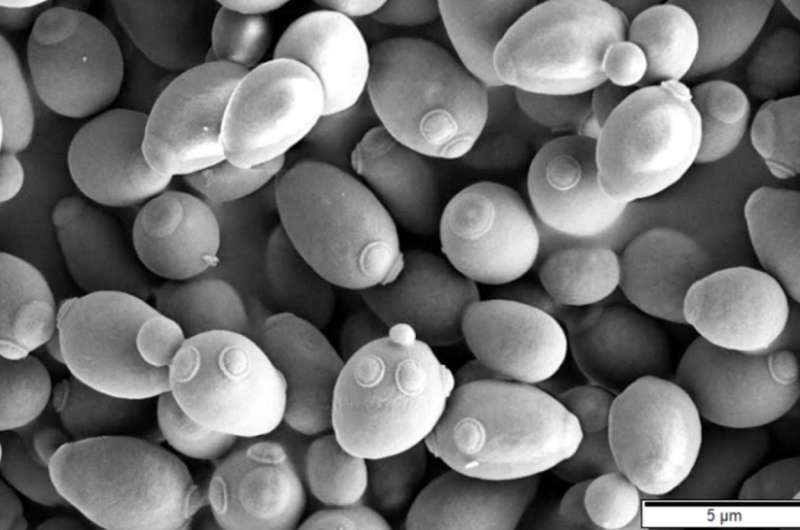

Saccharomyces cerevisiae is a yeast that is used to ferment lignocellulose from plants. During the pre-treatment of the biomass, various compounds, such as furans, acids, and phenols, are released which affect the performance of the cells. The use of bioprocesses is a cost-effective alternative to conventional production.

Studies aim to increase cell productivity.

A great amount of research has already been conducted in the field of lignocellulose. There are many studies in which researchers have genetically modified different yeast strains to increase the cell factories tolerance to different inhibitors with the aim to increase cell productivity.

An analysis of previous research for further development of efficient yeast has been made by the Associate Professor of industrial biotechnology and her colleagues.

When developing new cell factories, we want to use all the knowledge. More specifically, our goal was to combine and fine-tune genetic engineering previously shown to be favorable for the fermentation of lignocellulose.

The database grew as the researchers dug deeper into the previous research data.

It was difficult for us to choose from all the data. The different experiments made it difficult to compare the data and draw conclusions. The systematic analysis was done to help us with our research. We decided to summarize our results in a review after we came up with the idea of sharing the database and analysis with others.

The data from previous experiments was analyzed.

The researchers collected data from 7,971 previous experiments within 103 studies in which researchers had modified the tolerance of different strains of baker's yeast to the most common inhibitors in the pre-treated lignocellulose. Increased or decreased tolerance to individual and combinations of inhibitors was shown in the mutants included in the test.

The effects of the inhibitors on the cells are different for example reduced growth rate, cell survival and product yield. The effect is due to the presence of individual inhibitors and is affected by environmental factors.

The results were often characterized by strain and conditions. Although so much work has been done already, relatively few genetic modifications have been used in different strain backgrounds or for the conversion of different types of biomasses.

The development of new cell factories can be accelerated.

The work towards a new cell factory can be accelerated by applying the genetic modifications that show advantage in several different strains. The study describes the biology behind the various genetic modifications, which have been shown to lead to better strains. Increasing knowledge about the requirements for the development of more robust cell factories contributes to this.

More information: Elena Cámara et al, Data mining of Saccharomyces cerevisiae mutants engineered for increased tolerance towards inhibitors in lignocellulosic hydrolysates, Biotechnology Advances (2022). DOI: 10.1016/j.biotechadv.2022.107947 Citation: Research team follows nearly 8,000 paths towards better cell factories (2022, April 26) retrieved 26 April 2022 from https://phys.org/news/2022-04-team-paths-cell-factories.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.