Styrofoam is a ubiquitous, harmful, and nearly immortality single-use material that is long needed for a good, green replacement, and Cruz Foam is here to supply it. The startup creates packing foam out of shrimp shells, which are discarded by the seafood industry. It recently extended its seed round to accommodate the interests of Leonardo DiCaprio and is scaling up to meet the demands of its first major customer.

I met Cruz Foam co-founder John Felts at the event. His idea was to use a material provided by nature to create a substitute for expanded polystyrene foam.

The shells of shrimp, crabs, and other crustaceans are made from this material. It's tough and versatile, but it's also safe and easy to break down. It's produced in enormous quantities by the seafood industry, so there are almost no uses for it, so thousands of tons of shells pile up outside shrimp processing plants, most of which end up going to landfills. People are paying someone else to take their stuff.

Santa Cruz, Cruz Foam's innovation is a patented process for this surplus Chitin where shells go in one end and out the other, resulting in a lightweight, durable sheet of foam with many of the most desirable aspects ofEPS. It can be swapped in one-for-one with the common packing material, molded and cut to almost any shape. It doesn't smell like old shrimp, in case you were wondering.

The company said in an email that it is all bio-based and that other sources also play a role.

A block of Cruz Foam is on the right side after two days in moist soil, and it will probably look like that for a few hundred years.

Early on, the startup found that the foam could be tailored to meet different requirements for shape, rigidity, and so on. We don't want to introduce materials that are going to be a problem.

The company kept the lights on for a period after I met them with an SBIR award, with the Phase I and II awards yielding more than $2 million in non-dilutive money to work with.

I was worried that technical innovation wouldn't be enough to get their foot in the door in an industry as large and traditional as packaging. The team understood that it needed to find niches where it could attract corporate interest while keeping R&D costs down. Everyone is quietly looking for something better, and existing green alternatives haven't panned out.

The tide is turning against the category as the pervasive pollution it leads to is driven home by researchers. The recent revelation that practically every animal on the planet has microplastics in its bloodstream and organs probably comes as no surprise to anyone in ecology, but it is one of several now inescapable public realities that have companies running to invest in green alternatives to their most wasteful habits and supply chain links. Cruz Foam is as green as it gets, but it is three times the price, so it is not the best option.

The director of Cruz Foam watches a ribbon of foam being made.

Styrofoam and other plastic packaging products have historically been used by Whirlpool, but in recent years the company has pledged to go entirely renewable.

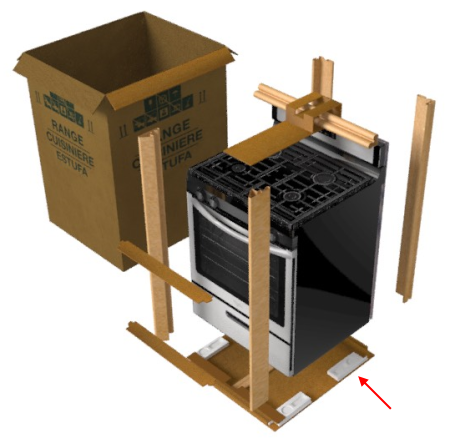

The foot bits by Cruz Foam are in the packaging.

Ron Vogle said that they as a maker of tens of millions of products a year are seeking to go above and beyond to eliminate the use of non-recyclable and single-use plastics. Sometimes the newest ideas don't come from the incumbents in the industry, but we seek innovation from everywhere.

A set of little molded feet was put together by Whirlpool and Cruz Foam to replace one of the last pieces of EPS used in its appliance packaging. It's one of the forms Cruz Foam can make and it's certainly possible but needs special machinery. This shell-based foam went from being a promising experiment to a major shipping product.

Major producers of TVs, food and drinks, even cars and parts are on the line, as they are in talks with numerous other companies to provide similar pieces. We have had to beat people away.

I kept in contact with Cruz Foam because they were about to be realized, despite a few false starts. With the maturity of the process, an industry ready to pay a premium for green alternatives, and a real live order for millions of pieces, the company seems ready to explode into prominence.

Cruz Foam has already received $5 million in capital and another $2 million in SBIR grants, so I think so. The latest revision of the seed round put it at $3.375M, which is more than the value of the round in late 2021. The round was extended in order to include film stars, but no further details were given about their stakes. Both will join as advisers.

A few years ago, he talked about his approach on stage at a tech conference. DiCaprio has been involved in social and climate advocacy for a long time. I wasn't able to get either of the new high-profile investors on the phone, but they included statements in the press release.

Cruz Foam is taking a major step in reducing the environmental impact of the supply chain industry. The mission to eliminate single use plastic makes me excited to join as an investor and advisor and I look forward to what we will achieve together.

Cruz Foam's consumer packaging has huge potential as the industry moves away from petroleum-based products and towards new biomaterial technologies.

In the Accelerator over the Sea

Tom Chi was one of the earlier seed investors, along with the sustainable Ocean Alliance, the Sony Innovation Fund, and Regeneration.VC.

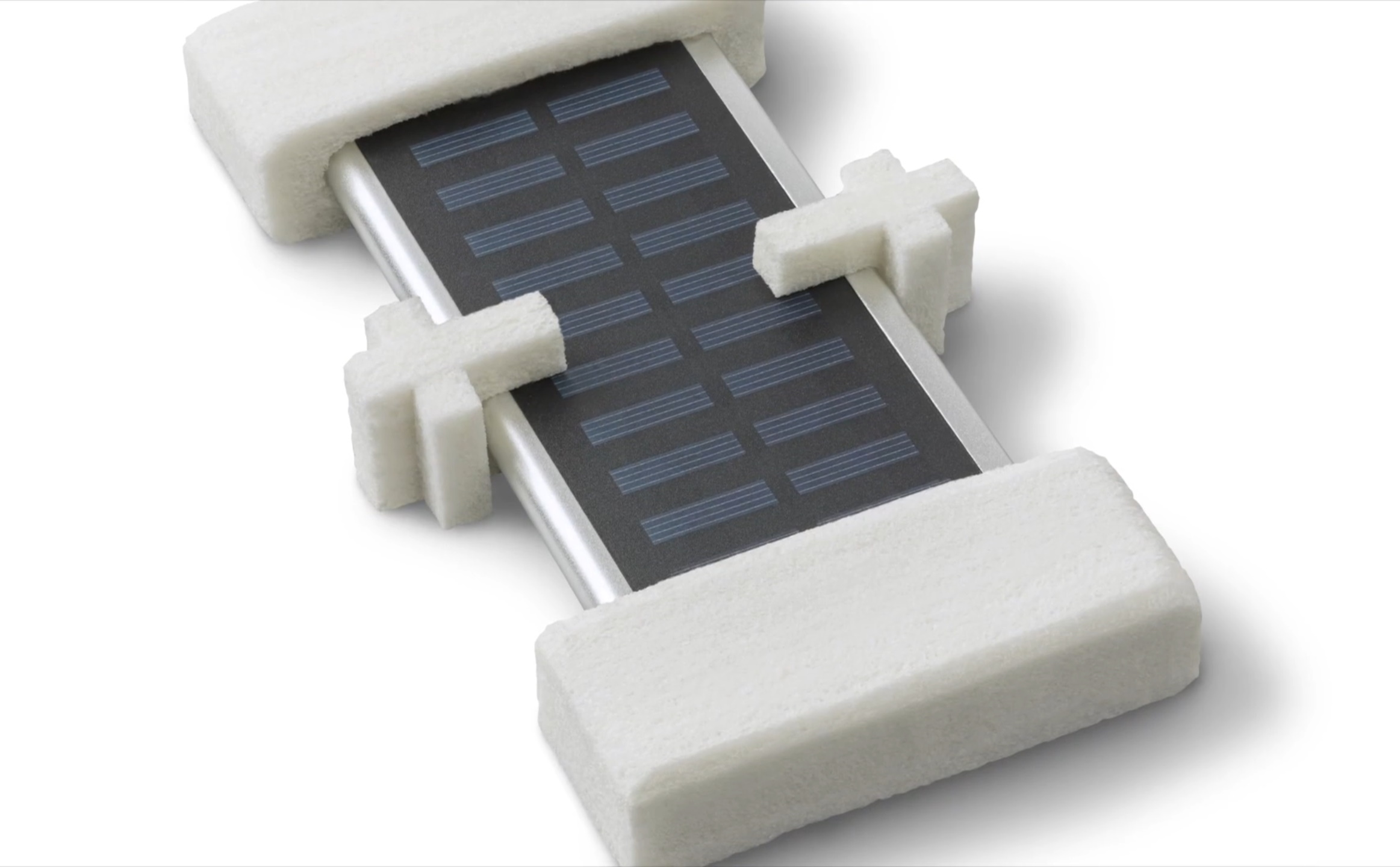

Cruz foam enclosures are used for consumer electronics.

Cruz Foam wants to become a major materials innovation company by using the versatile nature of this material.

I had suggested that the company's future was not simply as a foam maker, but as a kind of spinning.

He said that there is a lot of opportunity for this material beyond foam. We want to create new technologies around new types of materials that we can use in industries.

There isn't likely to be a shortage of raw material any time soon. If the shrimp reserves started running low, new insect-based feed companies have a similar problem.

The garbage bags full of dead insects have nothing to do with us, according to Felts. Most people wouldn't return a call like this.

Regulation is a stumbling block. Not that the government doesn't want this kind of green innovation to happen, but regulatory structures around composting and collection at scale aren't really prepared for it. There are dozens of labels and regulatory schemes for handling different types of waste.

You could throw it in your garden and it would break down in a month or two, but not everyone has a garden, and even if they did, they might not want decomposing sheets of chitin in it. If the company and material is to scale, it needs to fit within one of the waste categories already out there, and that is a long process of negotiation with city, state, and private authorities.

The end of life, recycling, infrastructure is so convoluted that it is a whole other conversation. A lot of industry standardization is required in how these things are messaged. He explained that if people see 5 different labels, they just throw it away. The new green, circular economy needs to build in this stuff from the ground up. It has to be easy.

That is all in the medium term for a company just now getting its legs under it, and trying to fulfill its first big order so that it can start answering the demand of the other companies. Cruz Foam has a long term plan and expects to raise money again very soon, perhaps as soon as summer, to begin the next phase of its shrimp-to-gold alchemy.