We've been shipping things across the oceans for centuries, and the world's supply chains increasingly rely on diesel-powered megaships. How do you decarbonize the industry? FleetZero thinks it can with electric vessels making short hops all the way around the Pacific, while relying on smaller ports and a clever battery-sharing scheme.

This is a serious problem for anyone looking at emissions and impact on the climate and oceans, as these huge ships carry a large proportion of the world's cargo and emit on the order of a billion tons of carbon per year. It can be difficult to overcome inertia, but there is a lot of opportunity here.

As engineers, Steven Henderson and Mike Carter understand the immense forces and challenges at play for anyone looking to change how the industry works. A thousand-foot ship with an engine the size of a building can be converted into a consumer vehicle. Even if you do it, how are you going to keep the crane powered up?

The industry has been paralyzed by the assumption that moving away from the dirty traditional methods would be both complex and costly. With margins already being eaten into by a variety of things, can they really afford to take on the expense of shifting to more sustainable propulsion? Smaller and less wealthy regions and companies could be out of the game entirely if costs go up.

FleetZero believes that its solution will be cheaper to operate. The reason for this is the fact that transoceanic shipping doesn't just go across the ocean from Eastern Asia to the West Coast. Due to the Earth's shape, it looks much longer but you have the benefit of being close to land to make deliveries.

If you don't have to travel several thousand miles in a single day, battery-powered shipping is just one of several puzzle pieces that fit together to form a potentially revolutionary picture.

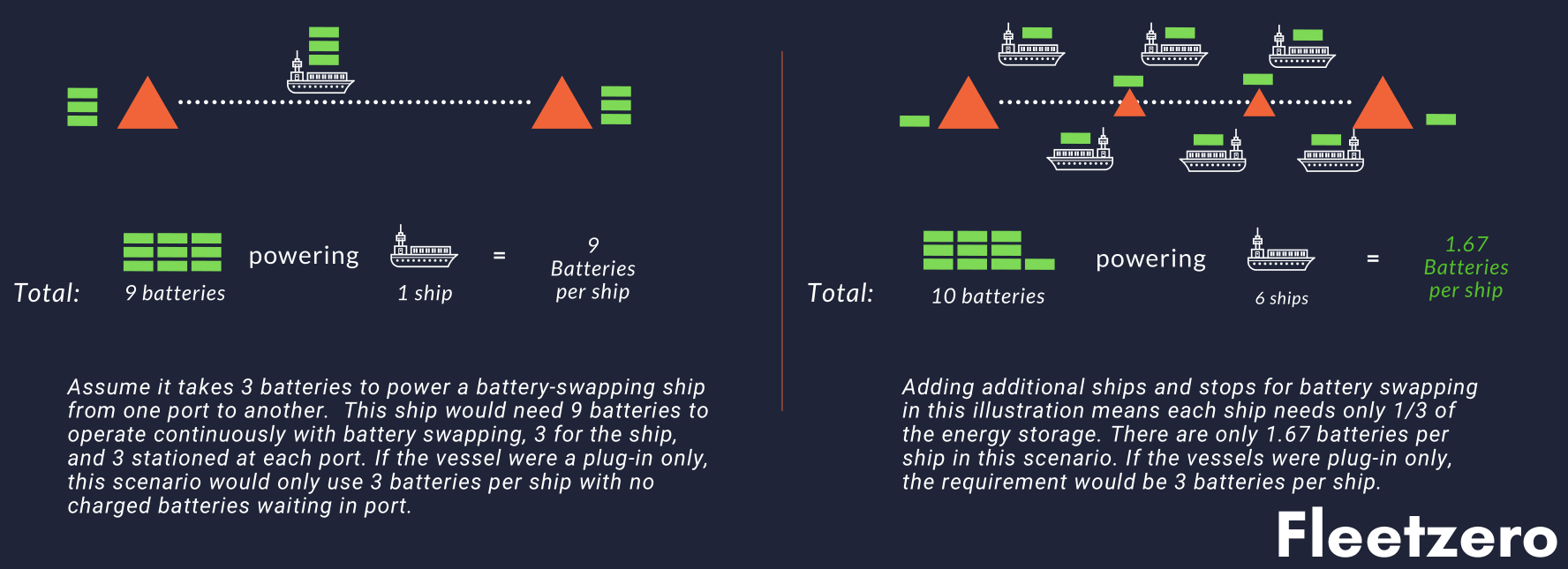

The weird economics of this is that the more ships you have, the less you have to pay. Henderson said that the batteries swappable wouldn't work for a plug-in vessel.

I had to model this out on the floor with my daughter's toy boats. If you only have one large ship that has to swap out batteries at each end, you must keep twice the number of active batteries around. It takes less battery capacity to move the same amount of cargo if you split the same capacity among several smaller ships.

This diagram of a simple case can help make it clear.

The image is from FleetZero.

The idea is that more and smaller ships use fewer batteries to move the same amount of cargo, assuming you have intermediate ports to make the swap network flexible. Plug-in vessels won't work partly because they carry a lot of batteries, but also because dockside charging may not be available.

The fleet buy-in cost is lowered by a huge amount if efficiency is used. This approach requires charging infrastructure at ports that may not have it. FleetZero's approach is to make the ship's batteries portable by putting them in shipping containers.

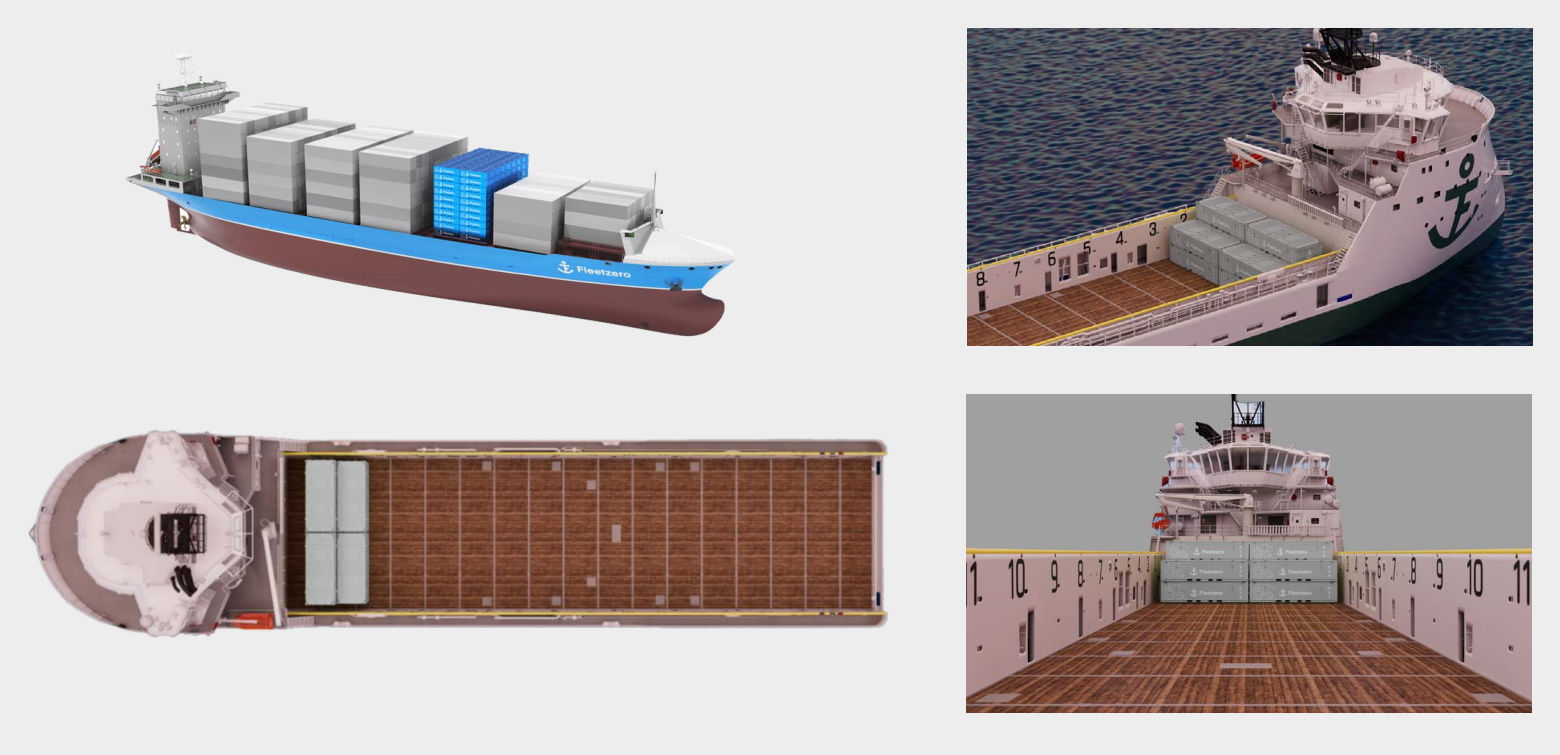

A rendering of a shipping container battery. The image is from FleetZero.

There are two answers to the question of whether or not these will take up a lot of space. If you remove the diesel engines and fuel tanks, you can open up a lot of space on a ship. You only have to take as many as you need.

Henderson said that they can put two batteries on a ship and change the range every time they load it out.

They can take advantage of off-peak electricity to charge the Leviathan batteries cheaply, or use it as temporary power for ships to plug into so they don't have to run their own diesel generators.

The docks are 50 years old and expensive toelectrify.

fitting this hypothetical network of ships to a real network of ports is the next puzzle piece.

Carter explained that a direct shot across the ocean on a 10,000-container megaship would require a battery stack a couple miles tall and was an engineering challenge. There are images of a proposed smaller test ship in this article.

You can access smaller ports if you are on the smaller side. Smaller vessels givelogistics companies more flexibility in their supply chain. If we look at places like Portland or Everett, they are not as well known, but there is less congestion and we can get cargo closer to the customers.

The image is from FleetZero.

The idea of having frequent pit stops for ships where they can drop off depleted batteries and pick up new ones to get them to their destination, like building a network of charging stations along highways, is also possible because of this. The local governments and port managers are enthusiastic about the idea of bringing in new business.

Using portable, container-sized batteries makes medium-distance travel in medium-size ships practical, which makes battery-powered shipping competitive by making it cheaper to operate.

It sounds promising, but also a lot. They are starting small, proving the concept, and will be ready to scale within three years. FleetZero has already raised $3.5 million in a combination of angel and pre-seed rounds, while they are just making their debut at Y Combinator's Demo Day in the latest winter cohort. Sam Altman, John Doerr, David Adelman, Flexport, My Climate Journey, and Joris Poort are investors.

The first task was to build the batteries, which they noted have a very different chemistry from most you would find out there, due to the extreme danger posed by fires on these ships. They used both passive and active fire suppression measures.

The next task is to load a bunch on the back of a 300-foot ship and test out the whole shipping and swap process. They'll begin converting vessels after obtaining the required regulatory approvals, and after raising more money.

FleetZero could begin commercial operations with luck and a lot of work. They have the advantage of having a lot of people rooting for them, and that would benefit a lot of people.