When bombarded with high-energy particles or X-rays, schillators emit light. In medical or dental X-ray systems, incoming X-ray radiation is converted into visible light that can be captured using film or photosensors. They are also used for research, such as in particle detectors or electron microscopes.

Researchers at MIT have shown that changing the surface of the material could improve the efficiency of scintillators by at least tenfold. The new approach could work with any of the existing materials, since it focuses on finding new materials.

It will take more time and effort to integrate their scintillators into existing X-ray machines, but the team believes that this method might lead to improvements in medical diagnostic X-rays orCT scans, to reduce dose exposure and improve image quality. The new scintillators could help with X-ray inspection of manufactured parts for quality control.

The findings are described in a paper by MIT students and professors in the journal Science.

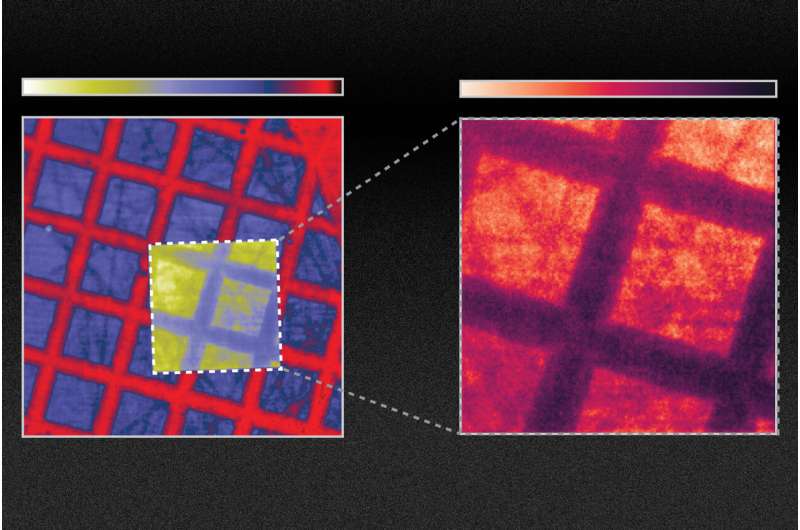

New materials that produce brighter or faster light emissions are the focus of much of the research in the field. The new approach applies new technology to old materials. The team found that it was possible to change the optical properties of scintillator materials by creating patterns at a length scale comparable to the wavelength of the light being emitted.

You can either glue on another material that has holes on the nanoscale, or you can make patterns inside the scintillators. The details depend on the exact structure and material.

Rivera says that the key to what they are doing is a general theory and framework. The researchers can calculate the scintillation levels that would be produced by any arbitrary configuration. The process of scintillation involves a number of steps. The framework the team developed involves three different types of physics. They found a good match between their predictions and the results of their experiments using this system.

The improvement in emission from the treated scintillator could be used to improve the image quality of medical scans. You don't want to irradiate your patients with too much of the X-rays, especially for routine screening, and especially for young patients as well.

He believes that this will lead to a new field of research in the field.

Soljacic says that while their experiments proved a tenfold improvement in emission could be achieved, by further fine- tuning the design of the nanoscale patterning, they also show that you can get up to 100 times improvement.

Computational simulations have enabled rapid, substantial improvements in the development of solar cells and LEDs, for example, because of the field that deals with how light interacts with materials that are structured at the nanometer scale. He says that the new models the team developed could facilitate similar leaps in technology.

Soljacic says that the ability to do this with scintillation was not possible until now. This work opens up the field of scintillation for the first time, and the team believes that it will enable higher resolution.

After many years of research, it is finally time for the concept of photonic crystals to be applied to scintillators.

The research team included Ali Ghorashi, Steven Kooi, Yi Yang, Zin Lin, Justin Beroz, Aviram Massuda, and Ido Kaminer at Technion in Israel. The work was supported by the U.S. Army Research Office and the U.S. Air Force Office of Scientific Research.

More information: Charles Roques-Carmes et al, A framework for scintillation in nanophotonics, Science (2022). DOI: 10.1126/science.abm9293. www.science.org/doi/10.1126/science.abm9293 Journal information: Science Citation: Improvements in the material that converts X-rays into light could allow a tenfold signal enhancement (2022, February 24) retrieved 24 February 2022 from https://phys.org/news/2022-02-material-x-rays-tenfold.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.