The detailed architecture of the Neutron rocket was unveiled by Rocket Lab on December 2nd, 2021. In a live-streamed event, the company showed off all the new elements that will make this "megaconstellation" launcher a serious contender in the coming years. The updated details include the rocket's design, materials, and reusability architecture.

The new vehicle builds on the experience of the Electron rocket, which was launched in the summer of 2017. The first electric pump-feed cycle was used to power the two-stage, lightweight carbon composite rocket. The engine will be used to launch the 300 kilogram (661 lbs) cargo. Since the beginning of the year, the Electron has launched 22 times and deployed 107 satellites.

In the summer and fall of 2020, Rocket Lab began experimenting with reusability by retrieving an Electron first-stage booster with a helicopter and net. The carbon composite skin and updated features of the rocket would be the same as on the foundation. On March 1st, 2021, Peter Beck gave the first glimpse at the Rocket Lab's Neutron rocket, an 8-ton launch vehicle design to service the satellite megaconstellation market.

Beck presented a design for a 40 meter (150 feet) two-stage rocket that could carry up to 18,000 lbs to Low Earth Orbit and up to 3,300 lbs to Mars or Venus. Beck provided updated details on the rocket in a live-streamed event last week, which included a new shape, a new engine, a new shell, and some rather unconventional design features. These include:

The new rocket engine is designed for reuse.

TheHungry Hippo is a unique captive design that enables streamlined first stage and reuse.

The world's first carbon composite large launch vehicle is called Neutron.

It was designed for a return to launch site.

The updated design of the Neutron will allow for a maximum of 15,000 kilograms (33,070 lbs), which is almost double the maximum of 8,000 kilograms to LEO. Beck summarized that the Neutron rocket is what rockets should look like in 2050, with full-reusability and tailor-made for the burgeoning satellite market.

Neutron is a different type of rocket. It is a new breed of launch vehicle where reliability, reusability, and cost reduction are hard-baked into the advanced design from day one. The best innovations of the past are combined with cutting-edge technology and materials to deliver a rocket for the future.

More than 80% of the satellites to be launched in the next decade are expected to be constellations, which have unique deployment needs that Neutron is the first vehicle to address specifically. We focused on our customers needs and worked back from there, like we did with Electron. A rocket that is right-sized for market demand can be launched quickly and cheaply.

There are new engines and Shells.

The use of carbon composite shells for rockets was pioneered by Rocket Lab. The first stage of the Neutron will have a carbon composite shell made from a new and specially-formulated carbon material that is lightweight, strong, and rugged enough to survive repeated spaceflight and reentry.

The automated fiber placement system will be used to build the carbon rocket shell. This will allow for rapid manufacturing and will make Neutron the world's first large carbon composite reuse launch vehicle. The new engine, designed and manufactured in-house by Rocket Lab, will enable reuse.

The methane gas generator cycle engine of the Archimedes can generate 1 meganewton of thrust and 320 seconds of specific impulse. The lightweight nature of the engine design makes it less complex and requires less thrust than other rocket engines. This allows for a more rapid development process.

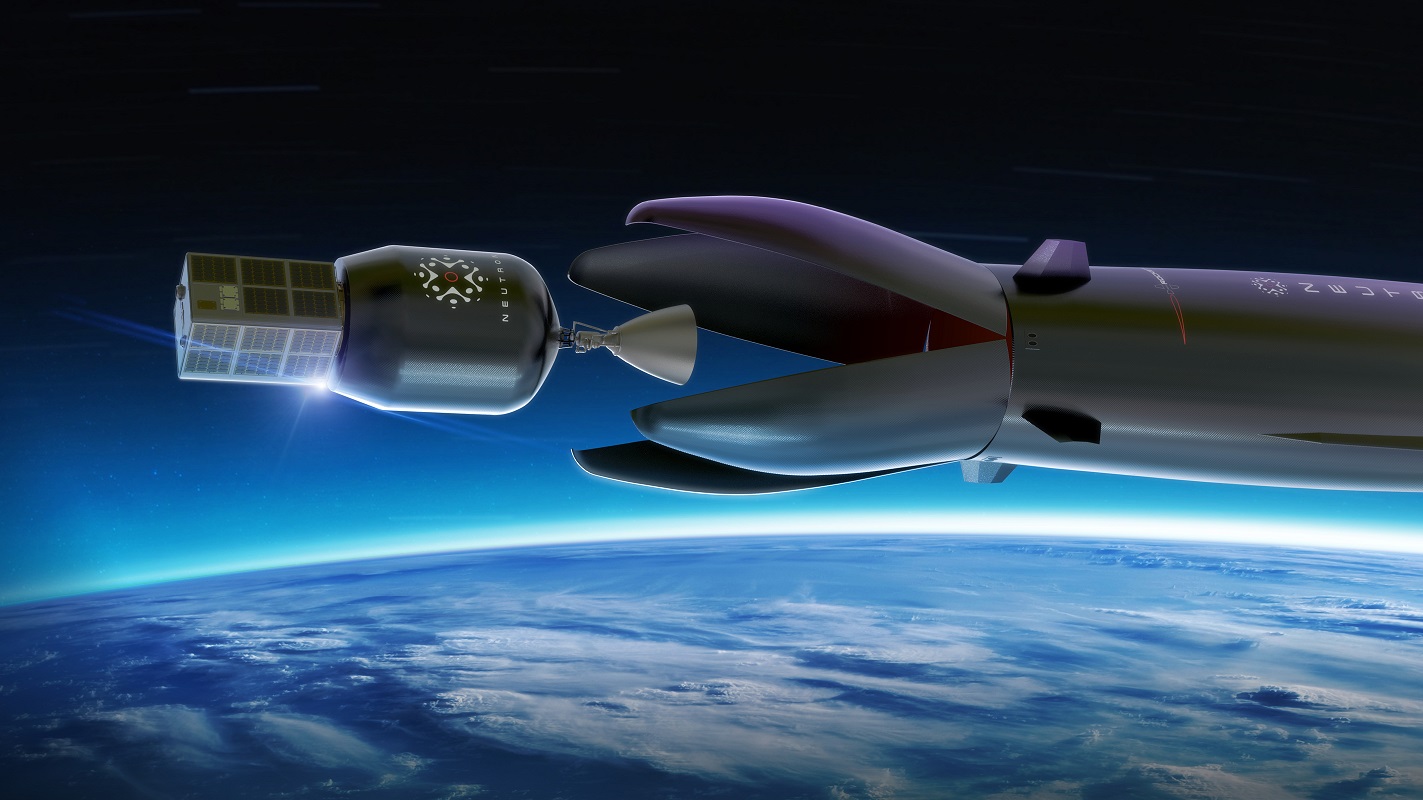

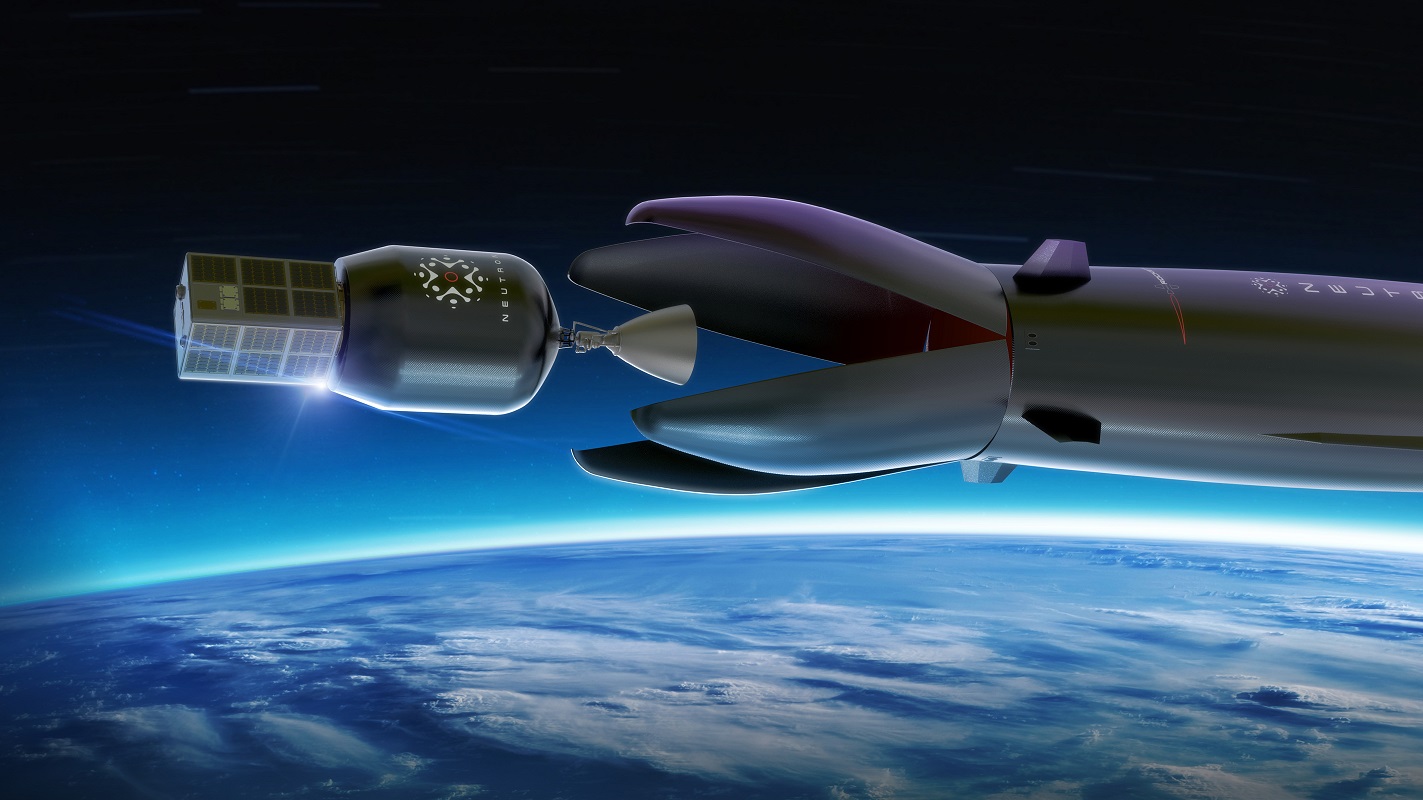

The second stage of the Neutron rocket is released in the artist's impression. Credit: Rocket Lab.

The first stage of the Neutron will be powered by seven engines, while the second stage will be powered by a single vacuum-optimized Archimedes engine.

The second stage is fairings.

Typically, the two cone-shaped halves are mounted atop a second stage booster. The cargo will be separated from the second stage once it is deployed. The fairings fall back to Earth after they have fulfilled this task.

The process of catching a payloads at sea is a challenge. The fleet of ships could only catch 20% of the time. By 2021, the company said it was abandoning the idea and would use fishing to get them out of the water.

The Neutron rocket has a new design called the Hungry Hippo, where the entire second stage and the first stage are covered in the rocket's first stage. Rather than falling away, the fairings will open wide to let the second stage and the first stage go down. A new second stage will be integrated after the first stage lands.

The second stage of Rocket Lab is made of carbon composite and is 20 feet long. The second stage can be made lighter and cheaper without the need for heavy shielding, since they have been spared from much of the extreme conditions experienced during launch and reentry.

The rocket design was presented on March 1st, 2021. Credit: Rocket Lab.

The design does away with the difficult method of capturing the fairings at sea and leads to an overall reduction in costs while increasing launch frequencies and flexibility.

Both launches and landings.

The entire design and development process of the Neutron rocket has been tailored to ensure reusability, while Rocket Lab has incorporated aerial retrieval to make the Electron's first stage re-usable. The shape of the rocket is wider at the bottom to provide a stable base for landing, and also removes the need for complex landing systems or legs.

The balanced structure means that the Neutron can stand securely on its legs before and during lift-off and return to the launch site to make a controlled, propulsive landing. This eliminates the need for costly infrastructures like strongbacks and launch towers. The purpose is once again to reduce costs by eliminating expenses while making reusability and repeated launches easier.

Rocket Lab has finished construction on a new site at NASA's Wallops Mid-Atlantic Regional Spaceport facility on the Virginia Coast. The inaugural launch of the Neutron rocket is planned for this facility. The company is in the process of selecting a rocket production and engine test facility on the East Coast.

The New Zealand-based company is likely to be giving other space launch services a run for their money with the expansion of their fleet and facilities. The Big Three, as well as the many smaller providers that have emerged in recent years, plan to get in on the megaconstellation market.

Further reading is Rocket Lab.