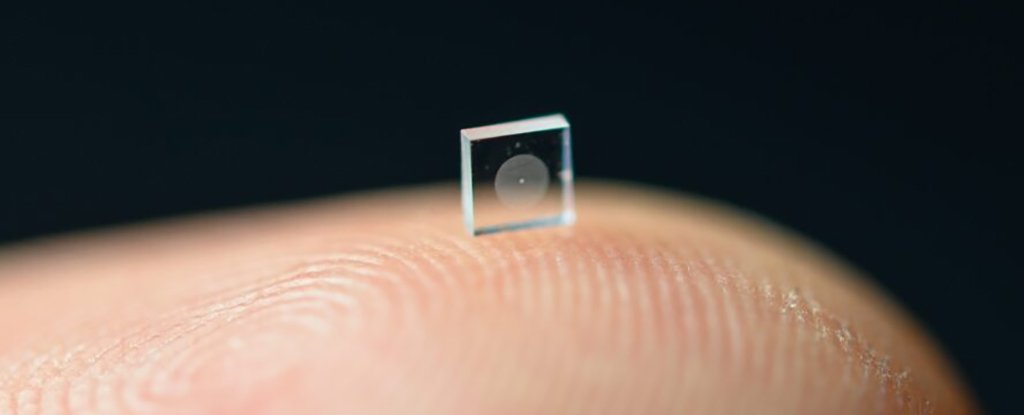

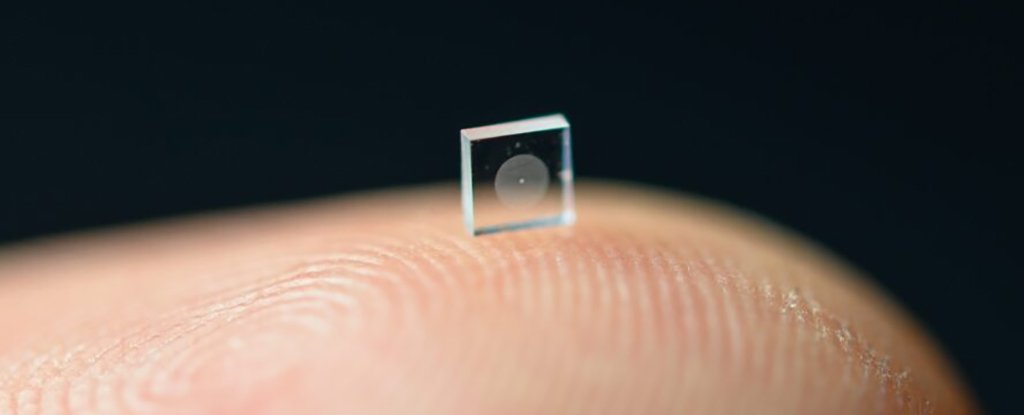

Scientific ingenuity means cameras keep on getting smaller and smaller, and the latest to appear is not only incredibly tiny, the same size as a grain of salt, but it's also able to produce images of much better quality than a lot of other ultra-compact cameras.

The metasurface technology that the camera uses is covered with 1.6 million cylindrical posts and it is able to capture full-color photos that are as good as images snapped by conventional lens.

The small device has the potential to be helpful in a lot of different scenarios, from helping soft robots explore the world to giving experts a better idea of what's going on inside the human body.

The old and new models of the camera. The University ofPrinceton.

"It's been a challenge to design and set up these little microstructures to do what you want," says computer scientist from New Jersey.

It was previously unclear how to co-design millions of nano-structures together with post-processing algorithms for this specific task.

One of the camera's special tricks is the way it combines hardware with computational processing to improve the captured image, using machine learning techniques to reduce blur and other distortions that otherwise occur with cameras this size. The camera uses software.

The images could be used for more than just enhancement. They could be used to detect signs of disease inside the human body.

The meta surface construction replaces the usual curved glass or plastic with a material that is half a millimeter wide. Computational modeling was used to work out the optimal configuration for each of the 1.6 million cylindrical posts.

The tiny camera has many cylinders. The University ofPrinceton.

The Herculean task of designing the size, shape, and location of the meta's million features and the parameters of the post-detection processing is completed by the published work.

It shouldn't be difficult to scale up production of these super-tiny cameras using procedures and equipment that's already in place because the glass-like Silicon nitride that the meta surface is made from is a material that fits in with conventional electronics manufacturing processes.

There's still a lot of work to be done to get this from the lab to a production line, but the signs are good that it's possible. We'll have access to cameras that can take a decent picture once that's done.

The use of miniature cameras as a covering layer to turn entire surfaces into cameras could be another use for them.

Felix Heide, a computer scientist from the University of Princeton, says that they could turn individual surfaces into cameras that have high resolution, so you wouldn't need three cameras on the back of your phone anymore.

"We can think of different ways to build devices in the future."

The research has been published.