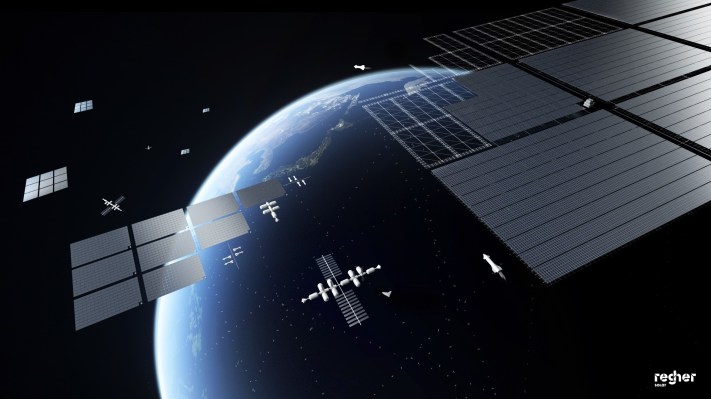

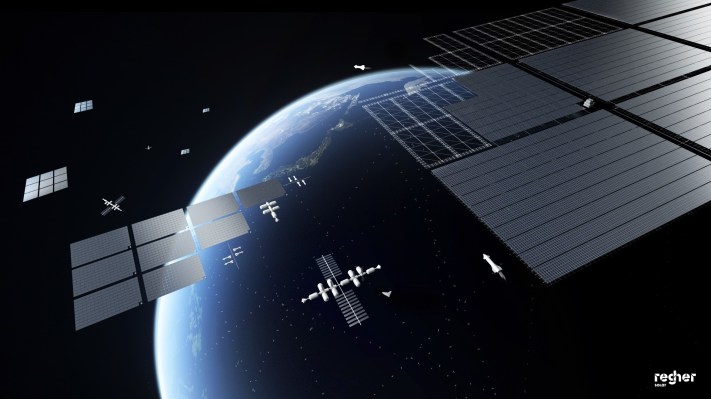

It is very simple math. What number of satellites will be added in the next ten years? What number of solar panels will they require? How many solar panels are available that will meet their needs? The answers are: A lot, a helluva lot, and not nearly enough. Regher Solar is determined to be a leader in space-quality solar panels by lowering the cost by 90% and making a lot more.

Although it is a lofty goal, the market and science seem to favor the company, which gives the company a boost. It is about finding the right balance between performance and cost while still being easy to manufacture. If there were an easy solution, people would already be doing it.

The solar cells that are used on the surface of the planets are different to those in space. Because there are no limitations on the size or mass of solar cells, you can make them larger, heavier, more efficient, and cheaper. However, space solar cells must be extremely efficient, light, and resistant to radiation and temperature fluctuations. This is a high-end product that can cost five to ten times as much, uses small-scale processes, and expensive materials.

Regher Solar has developed a space-grade solar panel that is comparable to dedicated space solar panels, but costs half as much. It can also be scaled with existing processes. You don't mind spending a lot on the highest quality panels if you are making a single geostationary satellite worth $200 million. It is only a small portion of the total cost. If you are looking to deploy 10,000 satellites that have a short life span, panels will start taking up more of your materials bill. A 20% performance loss doesn't seem so bad.

Stanislau Hrasimenka, CEO, and co-founder at Regher, said that their product is not perfect but requires incremental improvements and a better understanding of the space economy.

He explained that the tech was developed in a low-cost and high-volume environment. They start with a very expensive substrate (usually germanium or gallium arsenic) and require a lot of processing. Space-grade interconnect is an expensive glass, carbon fiber, or aluminum substrate that can be manually assembled to achieve high performance and low degradation. However, it cannot be scaled. They couldn't get 10 times as many of these.

We are on the verge of doubling, tripling, and eventually 10Xing the number satellites launched. They cannot just put terrestrial cells on top of them. They'd fail quickly and the well-respected makers of fancy IIIV cells won't have enough stock. Regher combines the best of both to make their cells space-ready but also cheap and quick.

He said that we are currently running an R&D pilot plant where we can produce small amounts of panels at 50 kilowatts. This is about 5% more than what the space industry produces. We designed the silicon package and made it compatible with automated production so we can transition from pilot to 10 Megawatts in one year. This is 10 times more than the space industry.

The product is not new but it does not use any unusual or novel techniques so it may be possible to ramp up. Herasimenka outlined some of the changes that were made to get space-like performance at terrestrial prices.

They reduced the thickness of silicon substrate, which paradoxically makes it more resistant to radiation. It absorbs less. They changed the doping and impurities in it to make it cure at low temperatures. This allows for any damage to be repaired by heating it to 80 degrees Celsius. Space-stable coating, interconnect, and bonding are all available. The bezel is also reduced, so that the sun-sensitive cells take up more of the area. They are also designed to be flexible, as shown in the images below. This allows them to fit into unusual shapes and increase their physical toughness.

The cost and expected life of each constellation-bound satellite was the key to determining how far you could go. This may seem counterintuitive but can pose a risk to Starlink, a constellation company that relies on satellites for its business. Unit economics are important when there are thousands of satellites. You don't want them to be more expensive or better than they need to be, especially if you plan to replace them within five years. You could have saved quite a bit of money if they were still running at 100%.

Herasimenka stated that constellation designers are designed for a specific period of time in a certain orbit. Nobody wants to live two weeks and nobody wants to live 15 years. Most people go to low Earth orbits and live there for only five-seven year. This is why we created our products. We don't care if they suffer after that because our customer does not care.

Regher's attempt at this emerging market earned Regher a spot in Techstars 2019, batch. After that, Regher began talking to manufacturers and negotiating deals. They were also awarded a NASA SBIR Phase I grant and an NSF Phase 2 grant totaling $1.1million. They had prototypes and some validation funding and collected $33M in LOIs this summer. Herasimenka stated that $50M more is being hammered out.

However, even though the prospects are great, the company must move quickly or else they risk being overtaken by others. He said that everything can change quickly and the market opportunity will disappear within a few years. Regher Solar clearly intends to seize that opportunity. However, they are currently looking for substantial investment to first bring their pilot up to speed and then to scale up the manufacturing lines. Although they are not ready to reveal the details, Herasimenka stated that they have a $5m institutional equity seed round, which should close before year's end, and $750,000 from individuals.

Regher is well-positioned with interest from established aerospace companies, and stamps (via SBIR), of NASA and NSF. It remains to be seen if the design or the actual production of the new panel will be the hardest part. They are about to find out.