Sila Nanotechnologies' next-generation battery technology was made commercially available Wednesday in the Whoop fitness tracker. This milestone caps a decade of Silicon Valley startup research and development that all aimed to find a way to pack more energy into a cell at lower costs.

Over the last few years, billions have been spent on improving battery chemistry. Various startups aim to replace either the anode and the cathode or convert material like silicon or lithium for solid state companies.

Sila Nanos' battery chemistry recipe uses silicon to replace graphite in a cell anode. This creates a cheaper, more energy-dense battery pack. BASF is also working to create a cathode that is high-energy dense.

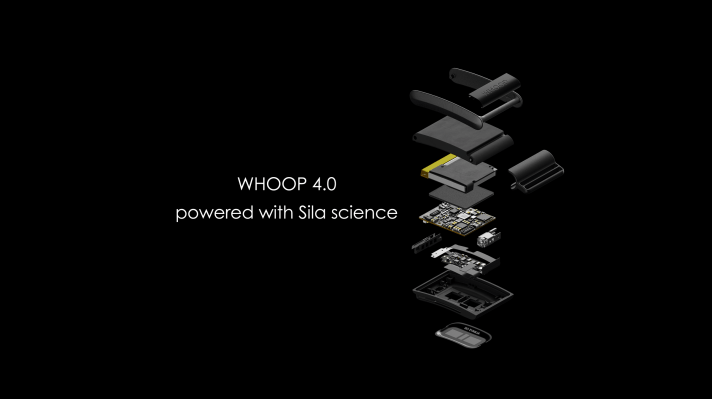

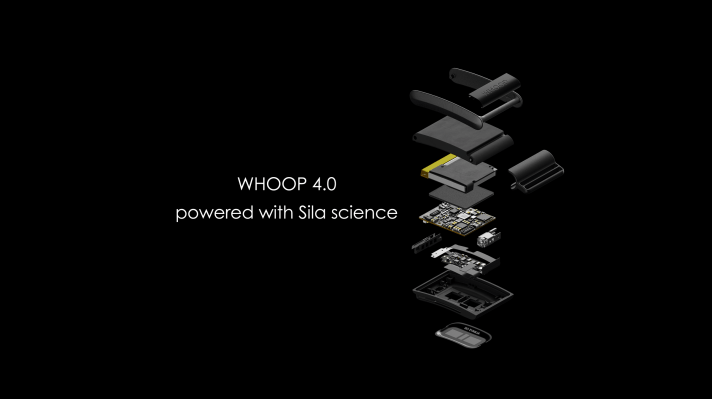

Although many companies are developing new battery chemistries, none have replaced the old technology in lithium-ion batteries. The Sila battery that will power the Whoop 4.0 is the latest performance and health tracker from the company. This could be the first time the world has ever seen a new-generation battery chemistry on the market in decades.

Although it may not seem like much, launching a small fitness tracker seems like a huge deal. However, this device is the first to be on the market and will prove our breakthrough over time. Over time, this will scale up and lead the electrification revolution of all things, Gene Berdichevsky (founder and CEO of Sila Nano) told TechCrunch.

Berdichevskys list of electrification of all items places electric vehicles and Sila Nano's role in their power is top-of-mind. The company is already making progress.

Sila Nano is a joint venture with BMW and Daimler in order to produce automotive batteries that contain the company's silicon-anode technology. The goal is to go to market by 2025.

Berdichevksy said that you can transfer this Whoop success to cars in many different ways. If you are looking for a long-range vehicle with a lot of range, you need a big car. Because there is nowhere to store the battery, the range of an EV will be shorter. As technology improves, we will be able to offer a car with 400 mile range in cities. This allows more segments of the automotive industry to electrify.

According to Berdichevsky, Whoop announced a $200 million raise earlier this month at a valuation of $3.6 billion. The Whoop 4.0 is a smaller wearable, 33% smaller than the previous Whoop 4.0. This is due in large part to Silas battery which has approximately 17% more energy density. A smaller wearable can be achieved by a more dense, better battery. Whoop also was able add features such as haptic alerts, pulse oximeters, skin temperature sensors, and a sleep coach without having to compromise its five-day battery lifetime.

Berdichevsky stated that one of the most important outcomes of enabling chemistry like ours allows you to create things that can't be otherwise built.

Whoops is referring to its new Any–Wear tech, which allows the wearable be integrated into new garments such as bands that can collect sensor information from areas such as the waist, calf, and torso.

Silas chemistry is not the only thing that makes a product a success. The product's ability to scale is what really matters. From the beginning, Silas roadmap has included scaleability.

Berdichevsky said that one of the first things we did was tell our engineers and scientists they could only use global commodity inputs to ensure we have enough material for millions of cars. Next, we stated that you could only use bulk manufacturing techniques. This means that you must use volumetric reactors instead of planar reactors.

The easiest way to understand the differences in reactor types is to use the analogy of cooking enough food for a large crowd. A large pot of chili (the volumetric) will go much further than individual pizza pies or planar reactors.

Berdichevsky told his team that any invention they made had to be seamless dropped into any battery factory process. This could be for cars, drones, or smartphones.

Berdichevsky stated that Sila Nano has already demonstrated scalability twice. It scaled up 100x from pilot to lab, using volumetric reactors about the size of one liter. Wednesday's partnership with Whoop marks its second 100x scaling, this time to 5,000-liter reactors. In relative terms, that means that a few people could fit into one of these reactors. Berdichevsky says that the next stage in scaling will be reactors large enough to drive a car through. This is fitting considering Sila Nano's goal of increasing automotive production over the next three year.

Berdichevsky said that although the materials are not available for use in cars today, they must be scaled up to 100x in order to have enough to actually deploy in them. We have made the same particles and powder in all scales.