Our new research shows that a new plant-based substitute for polyurethane foam eliminates the health risk of the material and is more eco-friendly.

Wherever a lightweight material is needed for structural support, you'll find Polyurethane foams. They are usually made with chemicals that are suspected carcinogens.

Polyols and isocyanates are used in the production of Polyurethanes. Despite its consequences for human health, the isocyanate component has largely remained despite the work that has been done to find replacements for the polyol component. There are bio-based foams that can be avoided.

We created a bio-based foam using a waste product from the paper industry and a vegetable oil curing agent to give it flexibility and strength.

The ability to create a system that is compatible with one another and that they physically create a gel quickly is at the center of the innovation.

Lignin is difficult to convert into a usable chemical due to its complex and heterogeneous structure. The world's first lignin-based nonisocyanate foam is believed to have been created using this structure.

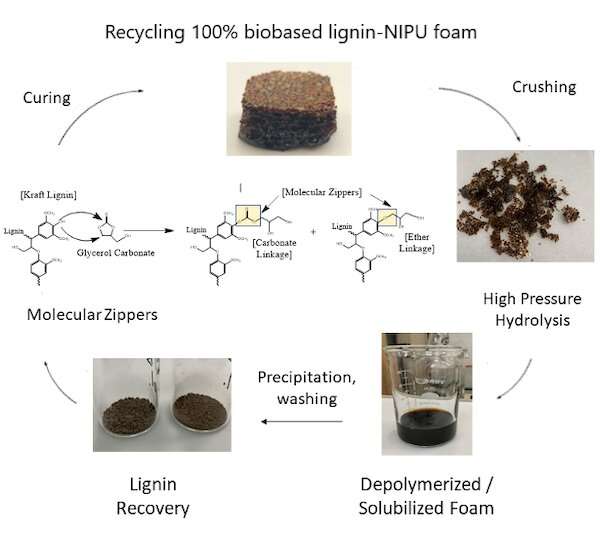

The foam has bonds that allow it to be recycled. The components used to make the foam can be used again.

The world's sixth-most-produced plastic is a type of foam. They will stay in the environment for a long time because they are designed forDurability.

The plastic waste problem for the world's oceans, land and air is one of the things they contribute to. Plastic can be found in almost every animal. Fossil fuel extraction contributes to climate change by contributing to the production of plastic.

The issue of carbon neutrality is addressed by the fully bio-based origin of our foams and the chemical recycling capability ensures that waste plastic has a value attached to it so it is less likely to be thrown away. Attaching a monetary value to things decreases the amount of waste that is discarded.

We hope the nature of these foams inspire others to design plastic with the full life cycle in mind The final destination of 90 percent of plastic waste needs to be designed so that it doesn't end up in the environment.

What are we going to do next?

The initial versions of bio-based foams are suitable for use in foam-core boards used in construction or for insulation in fridges. There is a lightweight and flexible version that can be used. The materials were found to be good in wet conditions.

Because of theirVersatility, Polyurethane foams are used a lot. A library of precursors that can be mixed to produce desired properties like strength and washability is being created.

There is more information about the chemical recycling of a non-isocyanate foam. The DOI is 10.1038/s41893-022-0

Journal information: Nature Sustainability

Under a Creative Commons license, this article is re-posted. The original article is worth a read.