Direct laser writing (DLW), also known as peripheral photoinhibition (PPI) direct laser writing, is a technique used to make intricate 3D nanostructures. One beam causes polymerization and the other quenches the excitation at the edges of the structure. Multifocal array can be used to improve capacity in some systems. Time and memory are very important in computing these beams.

A group of researchers from the university have developed a system that can achieve higher efficiency. Their work is in a journal.

The P 3 L system uses two channels, which allow the execution of different printing tasks and allow the system to fabricate highly complex structures with different periodicities.

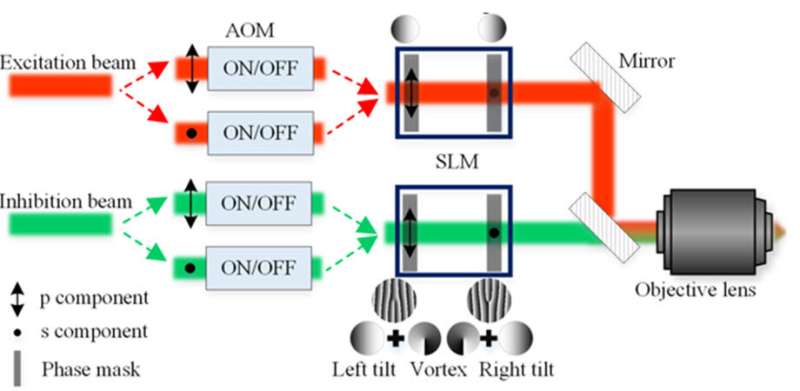

There are eight modules in the P 3 L system. The system starts with two channels, one with a solid spot and another with a donut-shaped beam. After stabilizing the two beams, they are split into two sub-beams. The individual on-off control of each sub-beam is provided by this. The two beams are combined to get the beams back. The beams are then adjusted. After passing through a microscope, the two beams are combined and focused on the same spot.

Without compromising on scanning speed, the individual control of each sub-beam allows the printing of non-periodic and complex patterns simultaneously. It's easy to adjust the position and separation. The proposed system is more flexible and functional than conventional systems.

The researchers were able to confirm the feasibility and potential of the system. They made a 2D sub-40 nm wire. A small suspended nanowire was also made. Two rows of alphabet patterns were created by the researchers after that. They fabricated 3D structures, including nonperiodic frames, hexagonal grids, wire structures, and spherical architectures.

The flexibility of the system is increased by the on-off control of each focus. The time cost for large-scale structures and patterns is reduced by the parallel scanning feature of the system. The P 3 L system is twice as efficient as conventional systems even if the structure is not uniform.

The work has the ability to overcome the current challenges in optical fabrication and enhance the fabrication of blazed gratings, microlens array, and metasurfaces, according to the work's leader. The proposed system could allow for the realization of portable, high-resolution, high-throughputDLW.

The results show that the proposed P 3 L system will be useful for the development of a wide range of fields that use nanotechnology.

There is more information about Direct laser writing breaking the diffraction barrier based on two-focus parallel peripheral- photoinhibition lithography. There is a book titled "10117/1.AP.4.6.066002."