The authors are Pol Sopea and David Grojo.

Even if it's hard to tell what's going on, lasers are still well-established in daily life. It is possible to find them in CD/DVD readers or medical applications like cancer and eye surgery, being essential tools in a vast range of multidisciplinary fields. Continuous progress and development from the first Maiman's Ruby laser to the attosecond lasers has resulted in this.

Ultra short lasers allowed high-intensity delivery in confined spaces, which was a clear breakthrough in the quest to get more intense sources. They allow the local modification of transparent materials with a low thermal budget, which is not possible with other laser sources. There are some demonstrations that include writing in glasses.

Ultrafast lasers opened the door to welding by irradiating the top one and focusing on the interface between it and the bottom one. The high intensity results in a rapid melting of both materials. This was demonstrated with a wide range of materials.

It's striking to know that the process is not applicable to bonding different types of wafers. Due to their small bandgap, the high intensities required for internal glass modification result in strong propagation Nonlinearities in Semiconductors.

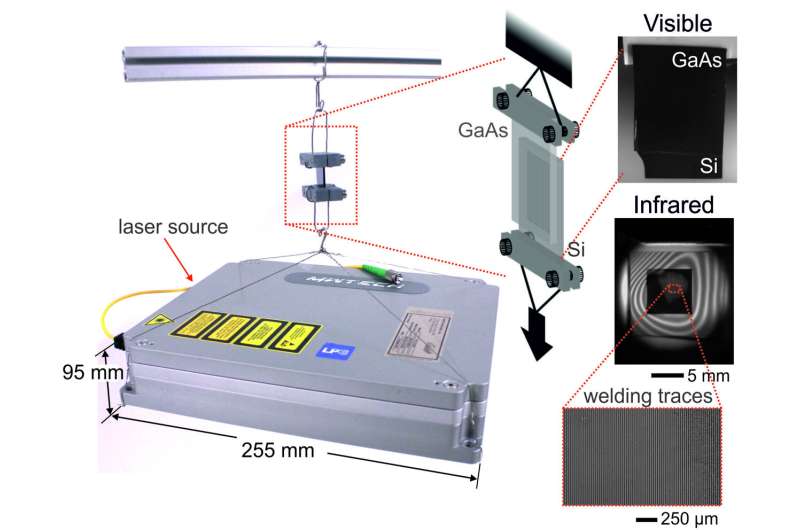

We had to think outside the box in order to tackle this challenge, and what at first seemed to be a step backwards resulted in a successful alternative. In the dicing of Silicon wafers, a small amount of light is used to create defects in the wafer. The relatively long pulse has a lower intensity than the ultra short one but can be absorbed by two-photon absorption. We used internal modifications not as defects but as strong bonding points to move to longer pulse lengths.

There was an added constraint during our first trials of welding Silicon pieces. If the gap at the interface is not very large, a Fabry-Perot cavity that impedes reaching a high enough energy density to melt both materials is likely to occur. The most intimate contact between the materials is needed for successful welding.

The first experimental demonstration of Silicon-Silicon laser welding was made after setting up the right conditions. We could extend this approach to other Semiconductors after an Optimization process. We achieved bonding between different parts while reaching strong shear force strengths in the order of tens of mpa. Ultra short laser welding demonstrations of other materials and the current techniques of wafer bonding are comparable to these values.

A technological barrier that has been lifted has been confirmed by this experiment. The ability to join elements with complex multi-material architectures in a direct-write manner is what distinguishes laser micro-welding from other methods. This will lead to new methods for manufacturing in electronics, mid-IR, and Microelectromechanical Systems. The thermal management of the most demanding micro-technologies, such as super- computers or advanced sensors, could be achieved with the emergence of hybrid chips.

Researchers can report findings from their published research in this story. Information about ScienceX Dialog can be found here.

Pol Sopea and his team wrote about transmission laser welding of similar and similar Semiconductor Materials. There is a book titled "LPor. 202200208."

Dr. Pol Sopea and Dr. David Grojo are researchers at the lab. The French National Center for Scientific Research and Aix-Marseille University formed a joint unit. Pol Sopea earned a PhD from the University of Barcelona and is currently working on new chip solutions. David Grojo is a scientist working on new and exciting opportunities to tailor material properties. His activities are funded by a grant from the European Research Council's excellence science pillar.