The lightweight, durable, and easily processed nature of polymers made them the most relevant class of engineering materials. Materials scientists have been researching the issue of recycling for a long time.

Increasing the service lifetime of polymers is an alternative route towards a more sustainable industry. A new idea is to teach the ability to self-heal from structural damage. The binding of copolymers on the surface of nanoparticles that are already used in industrial manufacturing has been found to provide an economic benefit.

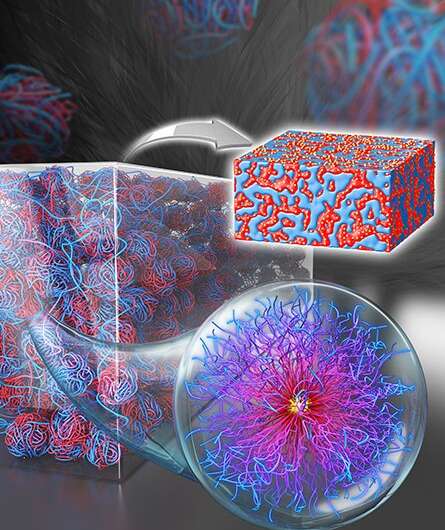

You usually think of atoms when you think of materials. A new approach to fabricate functional materials by assembling nanoparticle building blocks using a form of atom transfer radical polymerization was invented and developed by Matyjasewski. The properties of the resulting materials can be changed. New possibilities to vary the properties of engineering materials without changing their chemical composition are very beneficial in the context of recyclability.

Bockstaller's team tried putting copolymers at the surface of the particles to see if it would work.

It is possible to make materials more mechanically robust and easier to form with the help of polymers on the surface of nanoparticles.

The work shows how controlling macromolecular architecture can improve the properties of advanced materials.

There are two different types of copolymers that have self-healing properties. New structures were formed when copolymers were added to the surface of the particles. This discovery is needed to improve the recyclability.

This allows us to avoid failure. We can reduce the need to discard materials if they self-heal.

Strategies to maximize strength and toughness of self-healing materials will be explored by the group.

The research was published in a journal.

More information can be found in the article "Topologically Induced Heterogeneity in Gradient CopolymerBrush Particle Materials, Macromolecules". The book is titled "acs.macromol.2c01131."