Pantheon Design, a maker of industrial 3D printers from British Columbia, suddenly found itself getting orders from factories in the Midwest in the midst of the Pandemic. There's a reason. The restrictions in China made it difficult for these manufacturers to get parts out of the country.

One of Pantheon Design's e-mobility customers waited 18 months before receiving its injection molds. If your electric vehicle or home appliance order is taking longer to arrive, it may be because of port closings and lock ups in the factory of the world

For a long time, 3D printers were too expensive, slow, and short-lived to be economically viable for manufacturers, according to Bob Cao, co- founder and CEO of Pantheon Design. Smart people who have never been in a real factory run many of the 3D printing companies, which is hot and smelly, according to anentrepreneur. Their machines don't work all the time.

He says that they try to sell the idea for manufacturing while making the product for prototyping.

Five years ago, he and his co- founders bought a bunch of 3D printers to build products for industrial customers, but the third-party devices weren't meeting their expectations, so they set out to build their own.

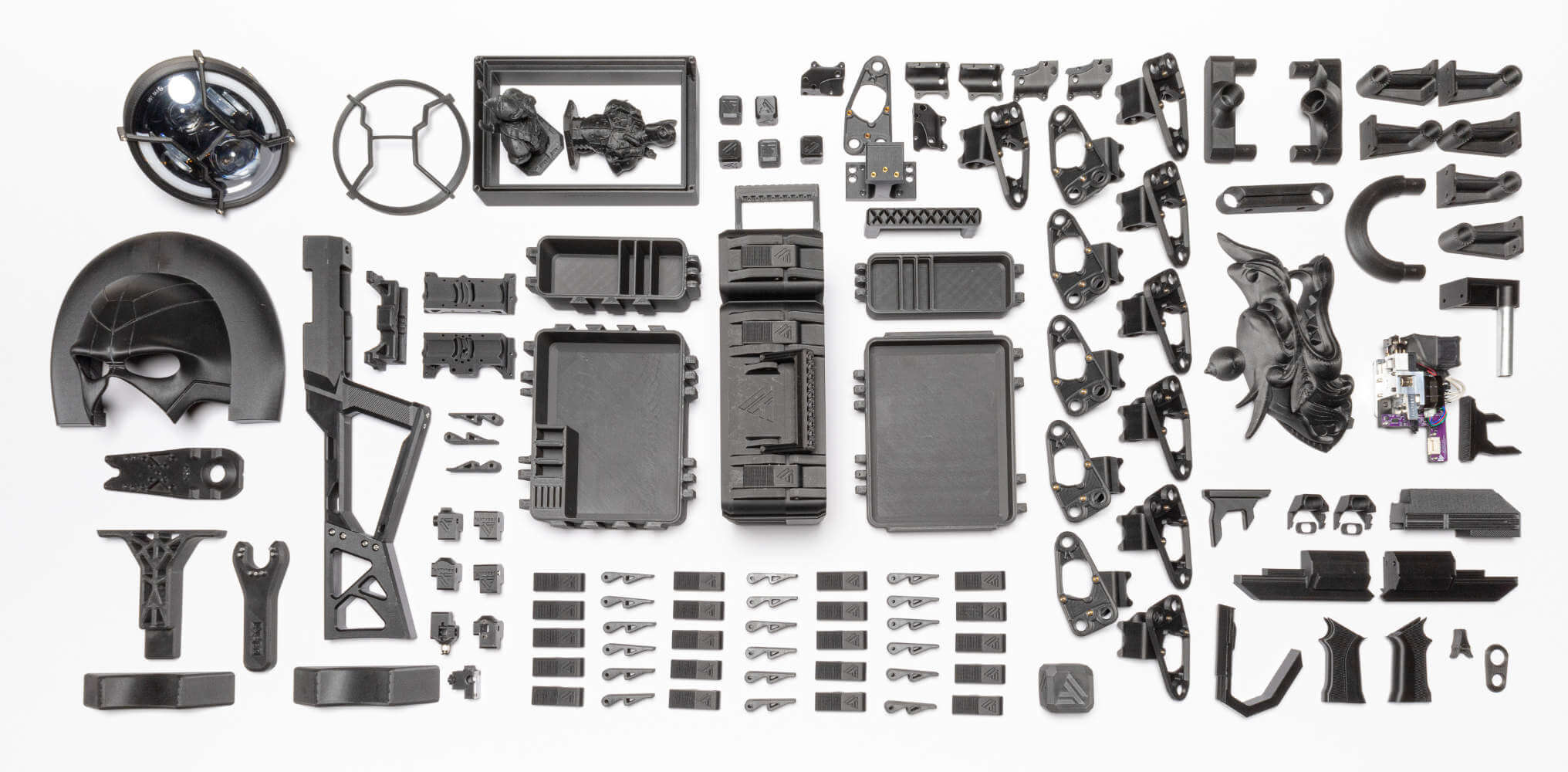

The parts were created using a 3d printer.

The cube measuring 300mm on each side and weighing 46.7 kilograms has been treated to achieve a durable finish. The startup's patented methods allow it to print carbon fiber parts that are 10 times faster than other options on the market. Even though it is cheaper than Chinese suppliers, it is still able to do it.

Since shipping the machine nine months ago, the startup has sold 40 of them. The bigger chunk of the company's revenues comes from selling filaments. Most of the company's customers spend between $500-800 a month on their 3D printers, which brings a nice 90% profit margin.

Pantheon Design has raised $800,000 in funding from investors in Canada and the U.S. Two of the company's proudest moments include printing the entire concept motorcycles for Honda and the sci-fi props in the movie The Adam Project.