Kevin DeMarco was asked if there was a robot that could prepare surgical equipment by his aunt several years ago. After investigating the problem with a colleague at Georgia Tech, where he was a research faculty member, he decided to leave his position to create the robot that his aunt once mused about.

One of the companies that was co-founding was RIF Robotics. RIF Robotics seeks to use a combination of artificial intelligence and robotic technology to relieve healthcare workers of the burden of mundane tasks so they can concentrate on clinical work.

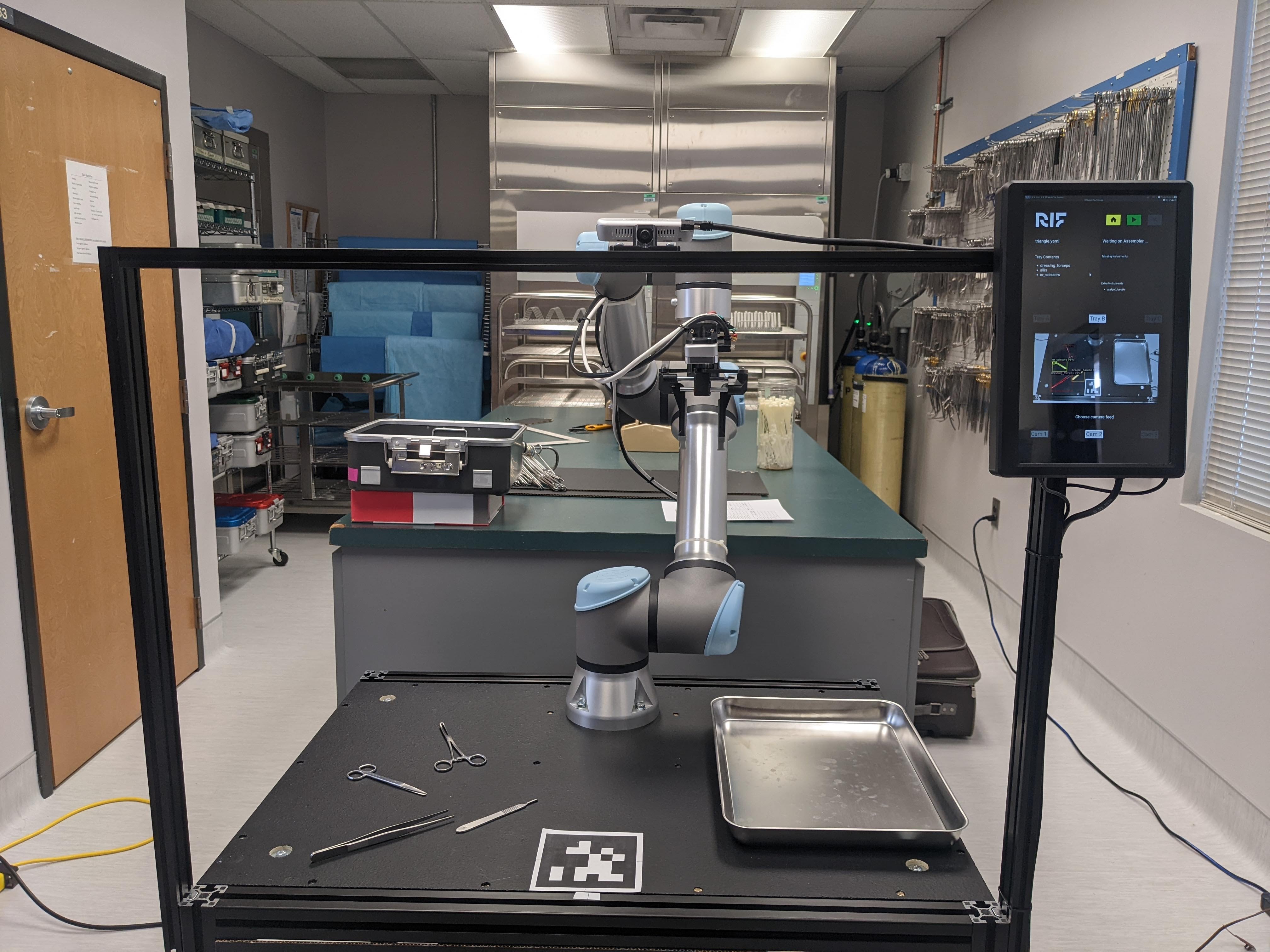

The image was created by RIF robotics.

It's difficult for technicians to clean medical equipment because they have to spend hours inspecting and cleaning tools. The pace in busy hospitals can be relentless, and some equipment requires over 100 steps to get rid of disease.

Costs can add up as well. According to one study, just 20 instrument errors can cost a hospital as much as $3,385. The research found that the cost to the hospital would be around $50,000.

RIF doesn't tackle cleaning. The prototype product was developed in less than two months and the startup claims it can save surgeons time. Two machine learning systems train on sets of real and synthetic images of surgical tools to help a robotic arm grasp and move instruments.

A lack of experienced surgical technicians is one of the major challenges that the sterile processing industry faces. Medical device manufacturers want to know how their equipment is used. They will be able to determine where to send sales reps. Hospitals want to improve instrument-level tracking and instrument inspection by using instrument-level data. Most hospitals only track at the tray level, but the industry would like to be able to track at the instrument level.

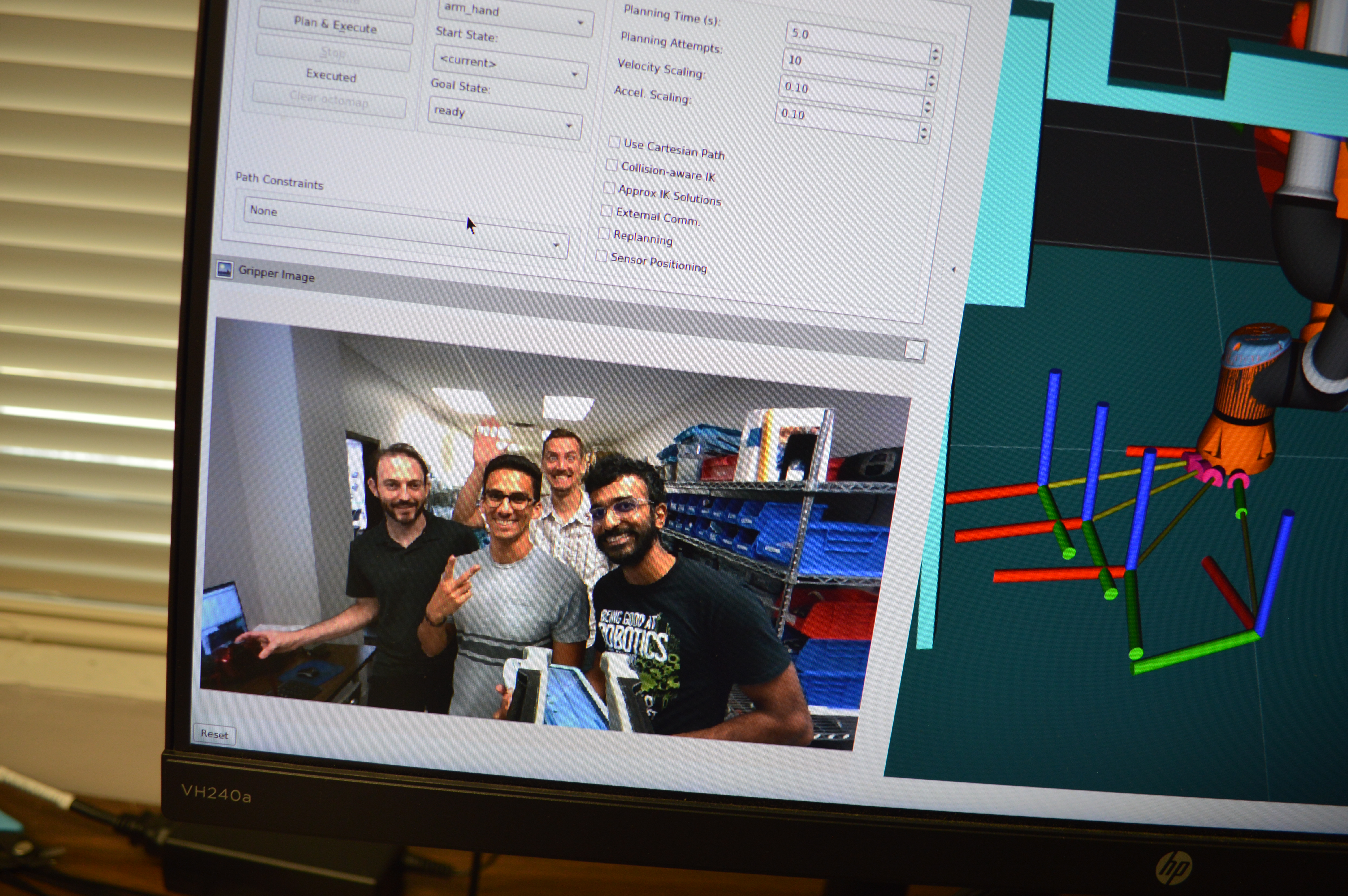

The image was created by RIF robotics.

Future prototypes will be able to identify more tools and determine if there is any leftover blood and bone on instruments. RIF has built a product that hospitals would use.

The Veterans Affairs and three Atlanta hospitals are interested in our product. We have an agreement with the Veterans Affairs that will allow us to conduct customer discovery and pilot studies at their facilities.

The company has a burn rate of less than $1,000 a month. The team isn't naive about the long road ahead RIF wants to hire a medical device industry expert after the round is over. The company will need three rounds of funding and close to four years before it becomes profitable.

The co- founders of RIF pose for a picture. The image was created by RIF robotics.

RST automation sells a semi-automated medical tool identification and organization system. Two other rivals, R-Solution Medical and steris, are developing robots to transport and store surgical trays.

RIF's solution is more capable, according to the man. The proof will be in the pudding as RIF tries to turn its prototype into a manufacturable product.

The healthcare industry is in dire need of new ideas. Products and solutions that are directly asked for by the industry and end users are being developed.