They stay around for a long time, even though they are great for a lot of things. Intropic came up with a set of enzymes that can be added to plastic at the beginning of their life cycle, before it becomes products. The company is trying to upend how plastic is made and how it's discarded.

Many of the most commonly used plastics are not harmful to the environment. In the normal course of plastic production, the pellet or powders are added with the help of the enzymes. The manufacturing processes used to make plastic products are unaffected. The products can be composted at the end of their life cycle.

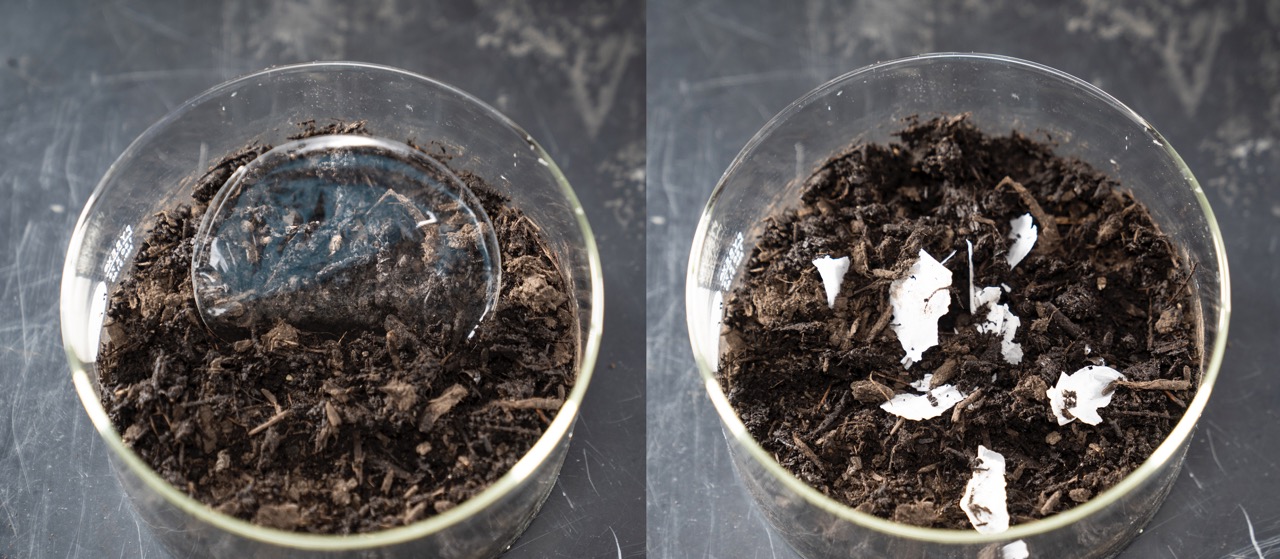

Jolene Mattson is the company's Process Engineer. The image is from Intropic Materials

The problem with current methods of disposing of plastic is that it takes a long time for nature to break down the plastic. The plastic raw materials are dissolved through a process called depolymerization thanks to the innovation from Intropic. Nature's normal decomposition processes can take care of the reduction of thepolymer chains.

The company claims that when the plastic is treated with the Additives, it can break down 98% faster than without it. The water-and-heat bath can break down the plastic in less than 48 hours at an industrial level. The same conditions can be found in commercial composting.

They are activated by temperature and water. Both are needed by us. If it were just temperature, you wouldn't be able to put this in a truck or a warehouse in the summer. All of a sudden, if it were just water, things would melt or degrade. We need both for now, but in the future, there are angles that we can explore to create more handles of control, which is a lot of fun.

The company told me that since the manufacturing process doesn't change, it could be rolled out very quickly.

We are working on a technology that will allow plastic to self-degrade. There are a lot of application spaces that are relevant. Food packaging is an enormous space that we are interested in, but there are lots of other single-use plastic that are also important. Think about all of the tech stuff. Our headphones come in a variety of materials.

A film of PLA is shown with biodegraded fragments. Adam Lau is an engineer at Berkeley Engineering.

The company is at an early stage of development and making progress. The proof-of-concept work has been completed and the technology has been shown to work in academic papers. Intropic is trying to scale up its manufacturing to the kilo scale.

For the sake of an example, let's say we're going to use a small amount of Additives. One kilo of can equates to 100 kilo of product. For the initial stages, that is more than enough. We want to find partners.

To maximize its force for good, and to tackle as much of the plastic problem as possible, the company is focused on ensuring its product will work at enormous scales.

We are trying to make this into a master batches. It will either be a powder or a pellet. At the beginning, we will be able to get into all sorts of products. It could be anything from a solvent-based coating all the way through to injection molded and roll-to-roll, covering the full spectrum of plastics manufacturing. It's fairly straightforward to integrate into many of these channels because of the fact that this is an Additive.

The image is called TechCruch.

The company is careful about making generalizations about the effectiveness of the product, explaining that it needs to be activated with heat and water for rapid breakdown. Even if the final product ends up in a landfill, I wondered if there would be a benefit to having these plastic Additives.

Even in a landfill environment with less-optimal conditions, having these enzymes inside could lead to something that has a much quicker degradation. It is definitely a possibility, but we would want to make sure that we are doing something right before making any strong claims about it. There is no reason to think that it wouldn't work.

I was struck by the fact that the Intropic team sees itself as part of a solution to the plastic problem. New, large-scale polymers and the new materials that have resulted were talked about by the team.

There has been a lot of investment in trying to explore new directions. We are a part of that but we are approaching it differently. We are embedded inside of materials. Different chemistries are being used to make new materials. I am looking forward to seeing those on the market. They are facing a different scale of the problem and a different type of integration problem.