Silicon, an element abundant in Earth's crust, is the most widely used Semiconductor material and is important in fields like engineering, geophysics and plasma physics The topic of how the material transforms when hit with powerful shocks has been debated for decades.

There is nothing left to discover because we have already studied Silicon in so many ways. There are some aspects of its behavior that are unclear.

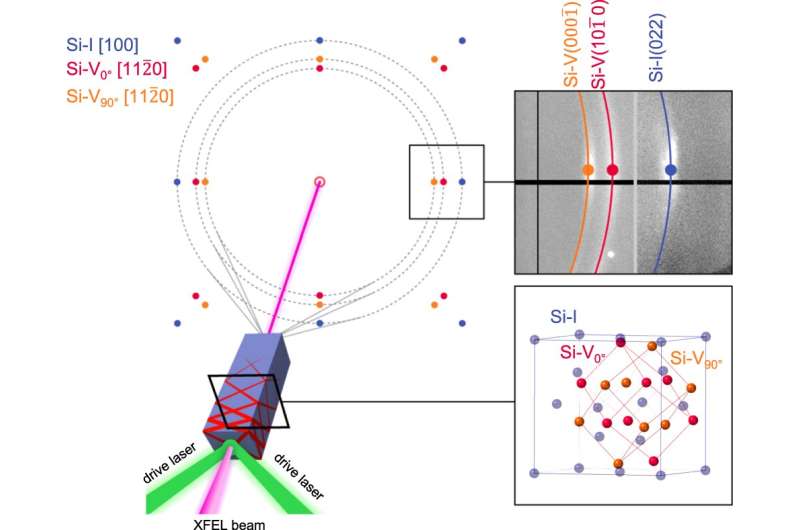

The first direct, high-fidelity view of how a single Silicon crystal changes during shock compression is now available. They used the X-rays from the LCLS X-ray laser to study the crystal. Their results were published in Nature Communications. More accurate models could be created that better predict what will happen to certain materials in extreme conditions.

The principal investigator of the experiment said that it was a great example of an experiment that needed to be done. "You have to start simple, with single crystals, to know what you're tracking and understand it in really detailed ways before you can build up complexity to give way to, say, the next Semiconductor of the 21st century."

It's time to rest.

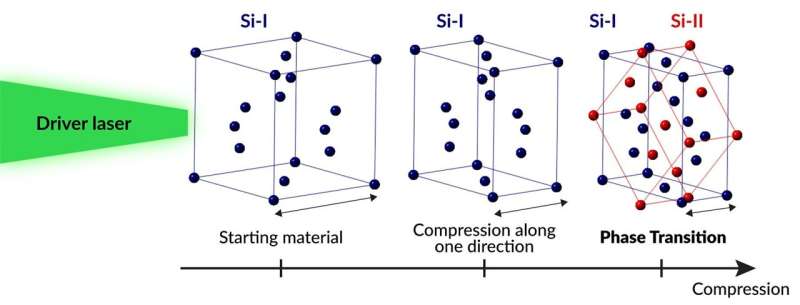

Researchers squeeze the material along one direction. The material needs to find a way to relax because of the stress created by this. Plasticity is caused by the generation and dispersal of defects in the material's atomic arrangement.

Researchers looked at the different features in shock-compressed Silicon as a sign of the plastic deformation. There was a different, defect-free strain suggested by the simulations.

The main relaxation mechanism in the case of Silicon is not the conventional plasticity. Silicon prefers to relax through the collective motion of its atoms and transform into a high-pressure structure instead of accumulating defects. It was difficult to prove this because it had been predicted.

It's apples to apples.

The researchers at the Matter in Extreme Conditions (MEC) instrument at LCLS were able to reach extremely high temperatures and pressures by sending a shockwave through a sample with an optical laser. They hit the sample with a laser. The researchers were able to observe how the sample's atoms rearranged in response to the increase of pressure and temperature by scattering some of the X-rays into a detector.

Many small crystals in different orientations were the focus of previous studies. Researchers were able to determine the average behavior of the material, but not the full picture. The researchers were able to follow the transformation of the crystal with a single sample.

The success of the experiment was due to sample quality and the X-rays from LCLS. We were able to access the fundamental materials science without having to factor in the X-ray source or micro structural defects in the sample that could change how the material behaves. It was more of an apples-to-apples comparison with the theory, allowing us to see what happens in what is as close to a model system as possible.

The springboard technique is used.

The design of the next generation of X-ray facilities is influenced by how materials respond to stress. TheMEC-U will produce unprecedented pressures combined with higher energy X-rays to probe a much wider array of conditions, allowing complex systems of direct relevance to be studied. The protection of satellites is one example.

We are looking at this as a technique development. It can be used to push the frontier for new materials and help illuminate the path to engineering these materials to benefit mankind.

The physics are correct.

To follow up on this study, the researchers will try the technique on different samples with more complex compositions to better understand the materials relevant to industry and Earth and planetary sciences.

The new data shows where the models that are used to predict how materials will behave need to be changed. There are other materials that respond in the same way. Extreme conditions such as micro meteorite impacts on space vehicles can lead to the use of high- performance coating. Understanding how these materials degrade will help us figure out how to prevent that in the future. Accurate, atomic-level models are the first thing.

The researchers plan to conduct more experiments to see what happens when they apply strain to a sample that is different in orientation. One of the most exciting aspects is the chance to uncover more unknowns about this element.

It's a soft spot for me. "Anything new I can learn about it is very interesting to me." Sometimes I have to stop and think about what we're talking about, because we're looking at the motion of atoms at high pressure. It's mind-blowing that we can get such clear information on a phenomenon that people have been looking at for a long time.

More information: Silvia Pandolfi et al, Atomistic deformation mechanism of silicon under laser-driven shock compression, Nature Communications (2022). DOI: 10.1038/s41467-022-33220-0 Journal information: Nature Communications