Researchers at The University of Texas at Austin set out to create a plastic that is hard and rigid in some places and soft and stretchy in others, similar to life forms such as trees and shells. Their success has led to a new material that is 10 times tougher than natural rubber and could lead to more flexible electronics and robotics.

Today's findings are published in the journal Science.

"This is the first type of material that I've ever written about," said Page. It is possible to control crystallization and the physical properties of the material with the application of light.

Synthetic materials have been used by scientists to mimic the properties of living structures. The flexibility and strength of living organisms can be combined with ease. Synthetic materials that mimic these attributes often fail, coming apart and ripping at the junctures between different materials.

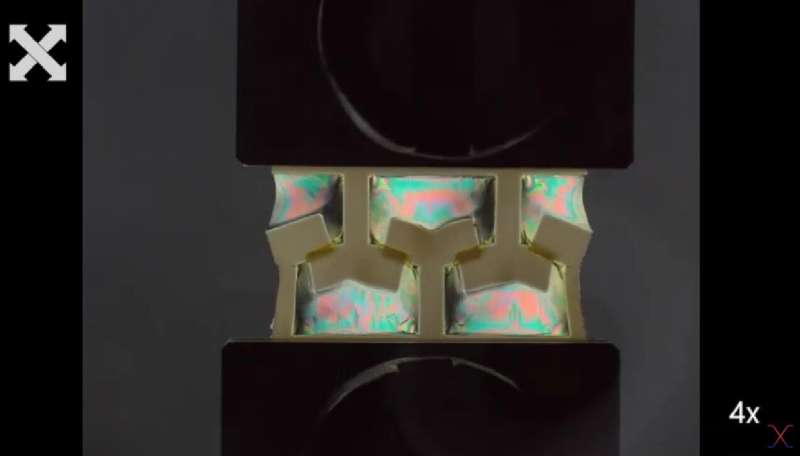

When bringing materials together, they want to come apart. Page and his team were able to modify the structure of a plastic-like material using light.

The building blocks for larger structures called polymers were formed with a small molecule that bind with others like it. After testing a dozen catalysts, they found one that resulted in a semicrystalline polymers similar to those found in existing synthetic rubber. There was a harder and more rigid material formed in the areas that the light touched.

The substance was stronger than most mixed materials because it was made of one material.

The catalyst is commercially available, the catalyst is commercially available, and the researchers used inexpensive blue LEDs as the light source in the experiment. It takes less than an hour to make the reaction and it is energy efficient and benign.

The researchers will try to make more objects with the material.

Adrian Rylski, a PhD student at UT Austin, is one of the authors.

The material could be used to anchor electronic components in medical devices or Wearable Tech. Strong and flexible materials are desirable in a robot.

The University of Texas at Austin and Henry L. Cater contributed to the research.

More information: Adrian K. Rylski et al, Polymeric multimaterials by photochemical patterning of crystallinity, Science (2022). DOI: 10.1126/science.add6975. www.science.org/doi/10.1126/science.add6975 Journal information: Science