Researchers at The University of Tokyo have shown that fatigue can start to occur at the same level of stress as a broken bone. The team was able to distinguish four different failure modes. The lifetime of industrial machinery could be improved.

Plant workers may be at risk due to damage to industrial parts. The scientists from Japan have created a simulation of a broken bone in a material that is widely used in domestic and industrial applications. The results of their work were surprising and could help prevent damage to industrial parts.

If you've ever been in a meeting and tried to pass time by playing with a metal paperclip, you might have noticed something strange. The paperclip may snap after too many cycles because it starts flexible and returns to its original shape. An example of fatigue is when cracks and defects build up as an object is subjected to stress. Machine or airplane parts that experience many cycles of stress, and for which a sudden failure could be catastrophic, are particularly vulnerable to material fatigue. It is possible to get a better understanding of the underlying process of material fatigue.

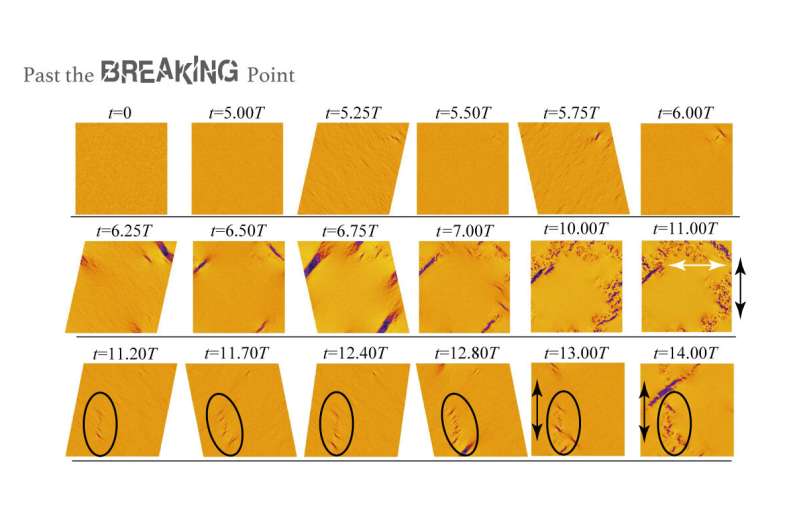

A group of researchers at the Institute of Industrial Science, The University of Tokyo, studied the physical mechanisms of low-cycle fatigue fracture in the case of glass or plastic. Pre-existing defects and grain boundaries can cause a fractured material.

It's not well understood how the corresponding mechanism in the material works. The scientists found that the stress required for a fractured bone is not as small as it seems. According to co-author Yuji Kurotani, the critical strain in disorder materials that correspond with the start of irreversible deformation is the same for both fatigue and monotonic fractured bones.

Higher density leads to slower dynamics. The shear deformation and density fluctuations are tied to the mechanical properties. The density fluctuations can be amplified by the shear until the sample breaks.

The situation is similar to a crowded train. There is a link between shear and density fluctuations. The results should be confirmed with experiments in order to better understand the initiation of fractured bones.

More information: Fatigue fracture mechanism of amorphous materials from a density-based coarse-grained model, Communications Materials (2022). DOI: 10.1038/s43246-022-00293-9