Thanks to the development of a surface cleaning technique that enables high-quality production, a group of researchers led by Cornell has unlocked the full potential of aluminum nitride.

The research was published in September. Two people are the lead authors. Both of the senior authors are professors of materials science and engineering.

According toZhang, aluminum nitride has gained significant research interest in the field of Semiconductor materials as it provides an unparalleled combination of high electrical and thermal conductivity. Due to its ability to operate at deep UV frequencies, the ceramic material has the potential to be used in light- emitting diodes and lasers.

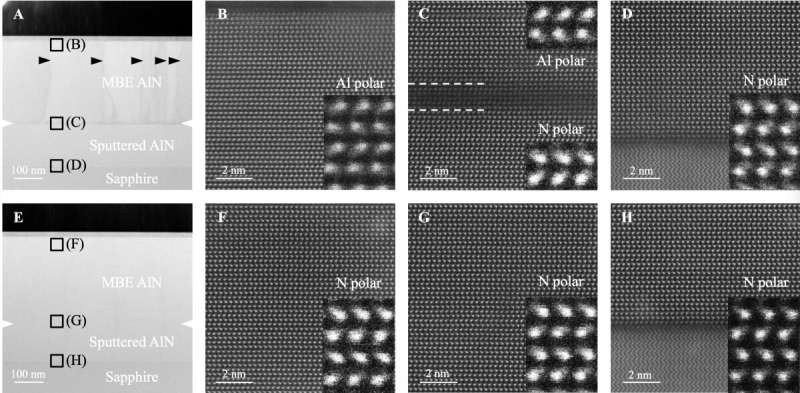

New performance advantages can be achieved in the nitrogen-polar form if the material's polarity is improved. A nitrogen-polar aluminum-nitride crystal has yet to be produced using a popular growth technique for high-quality Heterostructures.

Problems with the removal of native oxides and other chemical impurities on aluminum-nitride wafers have hampered the growth of aluminum-nitride wafers.

The research team developed an aluminum-assisted surface cleaning technique that allows the material to maintain its nitrogen polarity. The team was able to demonstrate the growth of nitrogen-polar aluminum nitride using this method.

Cho said that the successful demonstration provides a proof-of-concept for nitrogen-polar electronic devices.

The ability to generate deep ultra-violet photons is dependent on the defect control in aluminum nitride and its alloy. We are excited about the progress that has been made on the aluminum-nitride platform.

The co-authors of the research are graduate student Jashan Singhal and senior research associate Vladimir Protasenko.

More information: Zexuan Zhang et al, Molecular beam homoepitaxy of N-polar AlN: Enabling role of aluminum-assisted surface cleaning, Science Advances (2022). DOI: 10.1126/sciadv.abo6408 Journal information: Science Advances