Belgian investigators have improved the flavor of beer by engineering agene that is responsible for much of the flavor of beer and other alcoholic drinks. The research appears in a journal.

Beer was made in horizontal vats for hundreds of years. In the 70s, the industry switched to using large, closed vessels, which made it easier to fill, empty, and clean. Poor quality beer was produced by these modern methods.

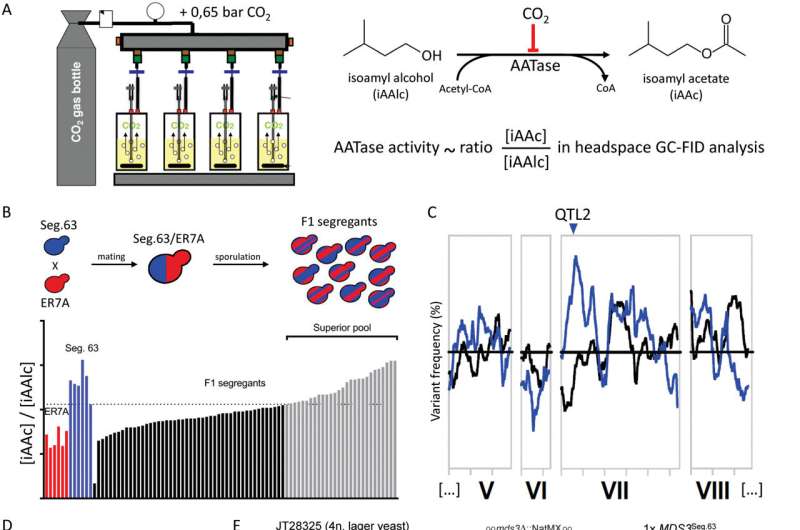

The yeast converts half of the sugar in the mash to alcohol and the other half to carbon dioxide. The closed vessels are affected by the carbon dioxide pressurization.

A professor at Katholieke Universiteit and his team pioneered technology for identifying genes that are important in yeast. They used this technology to screen large numbers of yeast strains to find the best ones to preserve flavor under pressure.

One of the most important flavors in beer, as well as in other alcoholic drinks, is a banana-like flavor.

The source of the banana-like flavor that was responsible for most of the pressure tolerance in this specific yeast strain is believed to be the result of a single deletion in the MDS3 gene.

In order to improve their tolerance of carbon dioxide pressure, Thevelein and coworkers used a gene editing technology to engineer a change in the strain's genetic makeup. Thevelein said that that showed the scientific relevance of their findings.

"This is the first insight into the mechanism by which high carbon dioxide pressure may compromise beer flavor production," said Thevelein, who noted that the MDS3protein is likely a component of an important regulatory pathway that may play a role in carbon dioxide inhibition of banana flavor production

In addition, the technology has been able to identify genetic elements important for rose flavor production by yeast in alcoholic drinks, as well as other commercially important traits, such as glycerol production and thermo tolerance.

More information: Ben Souffriau et al, Polygenic Analysis of Tolerance to Carbon Dioxide Inhibition of Isoamyl Acetate "Banana" Flavor Production in Yeast Reveals MDS3 as Major Causative Gene, Applied and Environmental Microbiology (2022). DOI: 10.1128/aem.00814-22 Journal information: Applied and Environmental Microbiology