A computer screen has gray and white specks on it. There is a landscape of equipment. A piece of Platinum thinner than a hair on a mosquito's back is bombarded inside the microscope. Scientists are looking for clues to explain how and why materials degrade in extreme environments.

The key to preventing large-scale, catastrophic failures in bridges, airplanes and power plants is to look closely at damage as it first appears.

As humans, we see the physical space around us and think that everything is permanent. It's stable because we see the table, the chair, the lamp, and the lights. There is a human experience that things can break suddenly. The evidence shows that these things are not stable. Many of the materials are not stable.

The ground truth about how failure begins atom by atom is a mystery, especially in complex, extreme environments. There are complicated processes that need a mix of specialized expertise to sort them out.

The results of the research were published in the journal. The results could help engineers predict a material's response to different kinds of damage and improve the reliability of materials in intense radiation environments.

Nuclear power plants can be brittle and weak by the time they reach retirement age. It takes decades of exposure to stress and radiation to break down materials. Strong structures can only be used for disposal and decontamination.

Brad said, "If we can understand these mechanisms and make sure that future materials are adapted to minimize these degradation pathways, then perhaps we can get more life out of the materials that we rely on, or at least better anticipate when they're going to fail."

The research was done in part at the Center for IntegratedNanotechnologies, an Office of Science user facility.

Damage to metals could be protected by atomic-scale research.

Grains are the particles in metals and ceramics. The stronger the material, the smaller the crystal. The scientists have shown that it is possible to strengthen a metal by engineering tiny, tiny crystals.

Brad said that it is possible to take pure copper and process it so that it becomes as strong as steels.

Radiation changes the crystal structure of grains and weakens them. A single radiation particle can break a crystal of metal like a cue ball. Radiation may only hit one atom head on, but that atom pops out of place and collides with others in a domino effect.

Radiation particles pack a lot of heat and energy and can melt the spot where they hit, which weakens the metal. The structures live in a constant hailstorm of these particles.

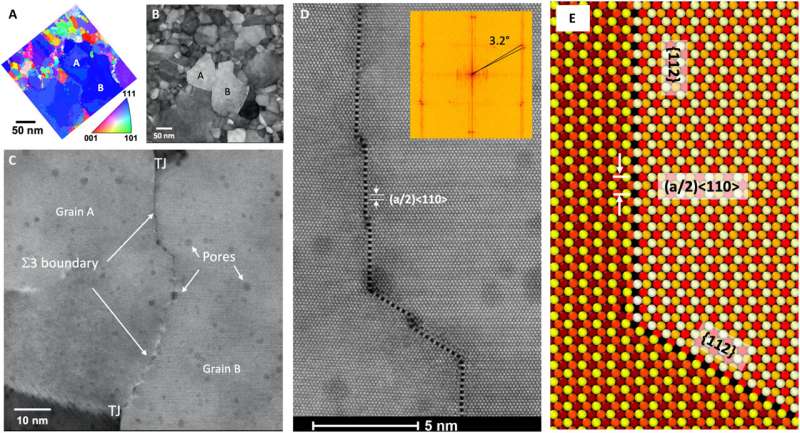

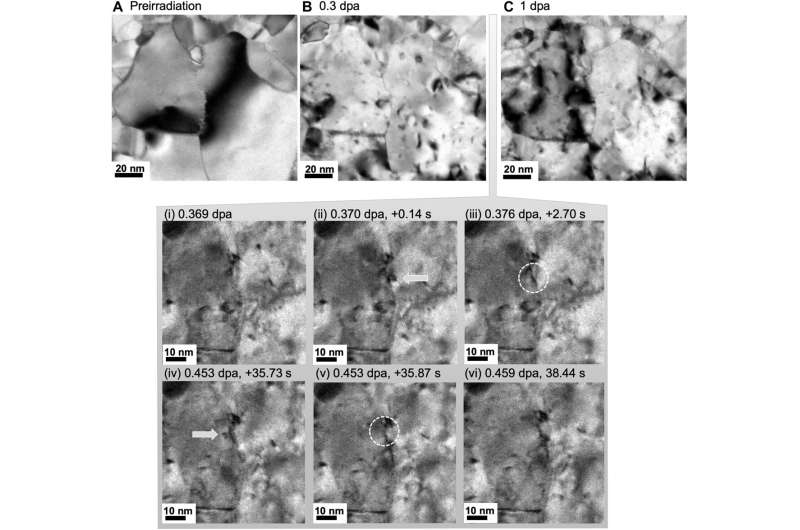

The atomic-scale changes to metals are caused by radiation. Researchers mimic crime scenes to understand real ones. The Science Advances paper details an experiment in which they used their high-powered, highly customized electron microscope to look at the damage in the platinum metal grains.

Khalid Hattar has been modifying and upgrading this microscope for over a decade. This one-of-a-kind instrument can expose materials to a wide range of elements. Scientists can observe degradation in real time. The Sandia team was able to see the atomic structure of the boundaries between the grains using higher magnification microscopes.

It is difficult to do forensic work.

Doug Medlin is a member of the team. Brad asked Doug to help with the project because of his expertise. Since the 1990s, Doug has studied the same problems.

Doug said that they were starting from a specimen that was three millimeters in diameter. We're going to zoom down to dimensions that are a few atoms wide. What do you do before and after the experiment? How do you make sense of those arrangements?

The team discovered that irradiating the Platinum causes the boundaries between the grains to move.

Cause and effect can be explained by computer simulations.

They had to translate what they saw into mathematical models after the experiment. It's difficult when some atoms might be different because of a physical collision. Theoreticians such as Rémi are used to separate the effects.

Radiation damage at the atomic scale is very expensive to model. It takes a lot of time to model the damage because there are so many moving atoms.

He said that Sandia has some of the best modeling skills in the world. The amount of damage caused by radiation is measured by the displacements per atom. Depending on the model, it can be as little as 0.2 d pa of damage. It can be up to 10 times that.

The combination of in-house expertise in atomic microscopy, the ability to reproduce extreme radiation environments and this specialized niche of computer modeling makes Sandia one of the few places in the world where this research can take place.

Only a few seconds' worth of radiation damage can be mimicked by high-end software. Hardware and software that can mimic longer spans of time are needed to understand the fundamental processes better. The remaining knowledge gaps are complex because humans have been making and breaking metals for hundreds of years. The long-term nature of the research has attracted Doug to this field for nearly 30 years.

He thought that was what drives him. It takes a long time to figure it out.

More information: Christopher M. Barr et al, Irradiation-induced grain boundary facet motion: In situ observations and atomic-scale mechanisms, Science Advances (2022). DOI: 10.1126/sciadv.abn0900 Journal information: Science Advances