Engineers can now predict the strength of metallic materials in a matter of hours instead of months or years using current methods.

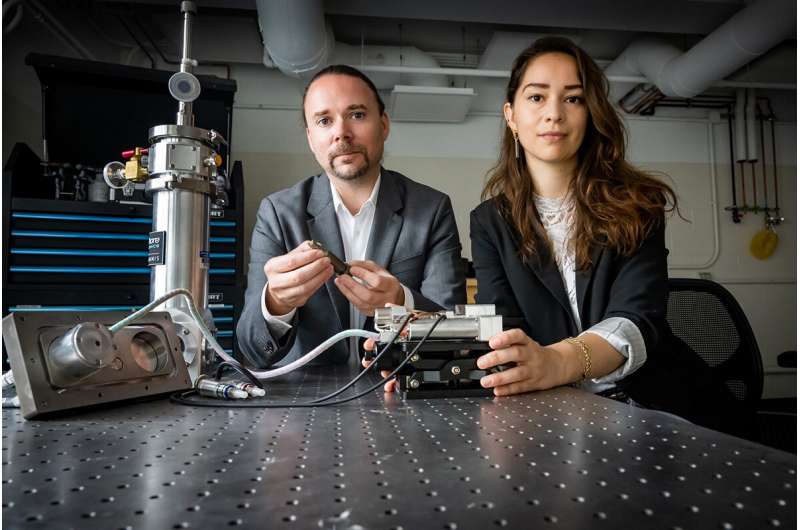

In a new study, researchers from the University of Illinois report that high-resolution electron images can be used to capture the events that cause metal failures. Scientists can use the new method to quickly predict the fatigue strength of any alloy and design new materials for engineering systems that are subject to repeated loading.

The results of the study were published in the journal Science.

Stinville said that the root cause of failure in engineering systems is fatigue of metals and alloys. Defining the relationship between fatigue strength and the structure is difficult because metallic materials have a wide range of features.

"We're trying to observe sparse, nanometer-sized events that control macroscopic properties and can be captured only by investigating large areas with fine resolution," Charpagne said. Traditional mechanical testing is costly, time-Consuming and does not provide a clear picture of the root cause of failure, which is why the current method for determining fatigue strength is used.

The researchers found that the statistical investigation of the nanoscale events that appear at the metal surface can tell the fatigue strength of metals. Stinville said that the team was the first to uncover the relationship using automated high-resolution digital image correlation collected in the scanning electron micrsocope. This relation was demonstrated on a number of key engineering applications using different types of alloy.

The fatigue strength that informs the life of a metallic part under a large number of cycles is correlated with the nanoscale deformation events. It is possible to quickly predict the fatigue life of metallic parts by discovering this correlation.

"Designing metallic materials with higher fatigue strength means safer, more resilient and durable materials." The work sheds light on the micro and nanoscale parameters to tune to design materials with a longer lifespan. The work will define a new paradigm in alloy design.

More information: J. C. Stinville et al, On the origins of fatigue strength in crystalline metallic materials, Science (2022). DOI: 10.1126/science.abn0392 Journal information: Science