The first durable coating that can quickly kill germs and keep killing them for months at a time could be a new weapon in the fight against germs.

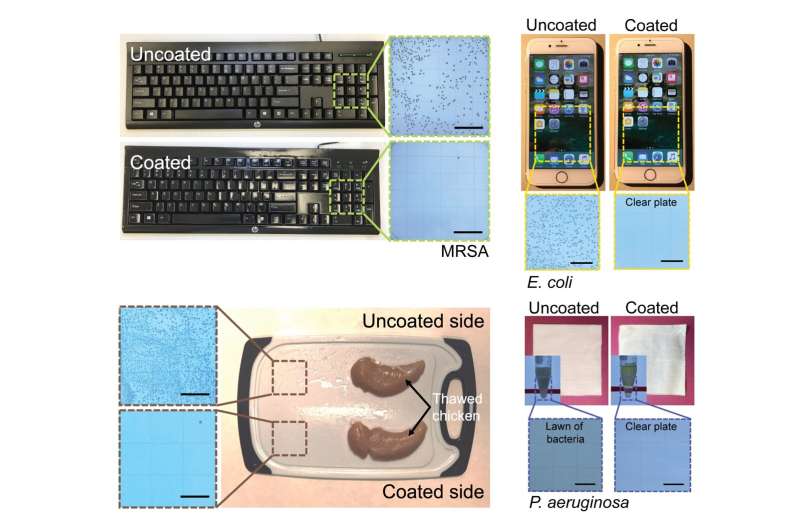

It was developed by a team of University of Michigan engineers and scientists. After months of cleaning and other punishment on real-world surfaces such as keyboards, cell phone screens and chicken-slathered cutting boards, it killed 99% of the germs.

Anisheja Tuteja is a professor of material science and engineering at the University of Michigan and co-corresponding author of a paper published in Matter.

He said that they have never had a way to keep touch screens clean. Disinfectant cleaners can kill germs in a few minutes but they don't stay on the surface long. We have long- lasting antibacterial surfaces made of metals like copper and zinc, but they take hours to killbacteria. Both worlds are offered by this coating.

The coating combines tried-and-true ingredients in a new way to get its germ-killing power. Tea tree oil and cinnamon oil have been used for centuries as safe and effective germ killers. The coating is made from a tough, varnish-like substance that is commonly used on furniture.

Some of the antimicrobials we tested have been approved for use as food enhancers. Polyurethane is a very popular coating. We did toxicity testing to make sure that our particular combination of ingredients is even safer than other antimicrobials.

The study's tests show that the coating can kill germs for up to six months before the oil begins to evaporate and the effectiveness of the spray is reduced. Tuteja says it can be recharged by wiping it with fresh oil, which will absorb the new oil and start the cycle again.

According to Tuteja, the technology could be commercially available within a year.

The key challenge was to combine the oil and polyurethane in a way that let the oil molecule do their germ-killing work while preventing them from evaporating quickly. A stable matrix was formed by the combination of the smaller oil molecule and the cross-linkingpolymer molecule.

The oil molecule can't penetrate the cell walls if they're tethered into the matrix. They found a middle ground by partially cross-linking the materials, which allowed some of the oil molecule to do their work, but kept others bound to the polyurethane.

Tuteja said that there was some trial and error but that only a small amount of the oil did what they needed. The oil that's cross-linked into the matrix helps the coating last longer.

The researchers wanted to find a combination of active ingredients that would kill a wide variety of germs. They collaborated with co-corresponding authors Christiane E. Wobus and J. Scott VanEpps to identify a sample of microbes. They found a balance of antimicrobials that were effective and cheap.

Tuteja emphasizes that they're not locked into one formula and that the team's understanding of individual ingredients' properties allows them to adjust the formula for specific applications.

Tuteja said that the goal is to develop a library of underlying material properties. If we are able to understand those properties, we can develop coating to meet specific needs.

The University of Michigan is trying to get a patent.

More information: Abhishek Dhyani et al, Surfaces with instant and persistent antimicrobial efficacy against bacteria and SARS-CoV-2, Matter (2022). DOI: 10.1016/j.matt.2022.08.018 Journal information: Matter