There were procedures that were sloppy at the facility. Cronobacterbacteria increased in number. America was in a shortage when the FDA acted.

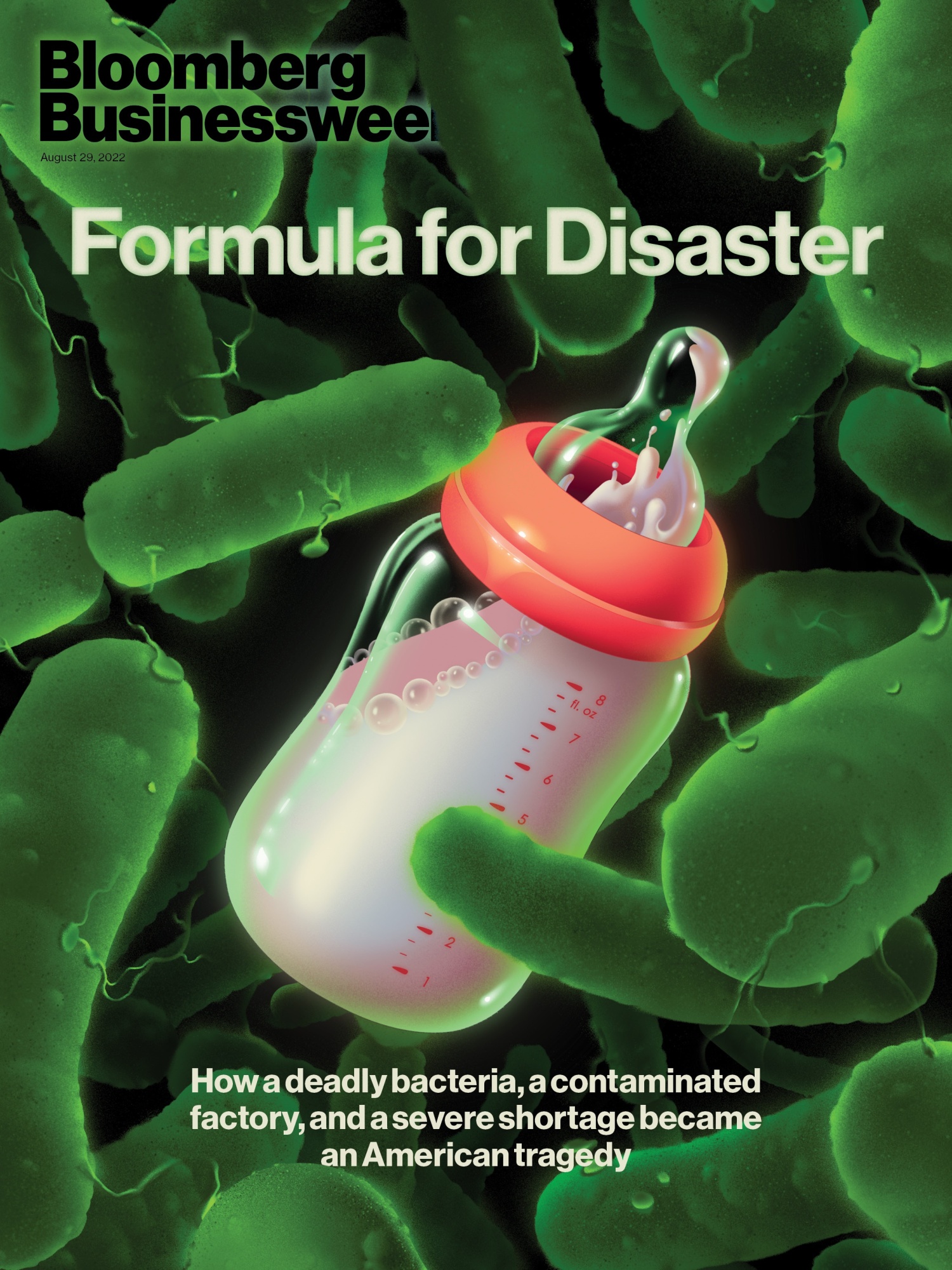

20% of the infant formula produced in the US comes from a plant in southern Michigan that has been there for more than 50 years. The country's most popular brand is made by it. The US Food and Drug Administration had an annual inspection that was one year late because of the Covid-19 restrictions. Cronobacter sakazakii, which can survive for months, sometimes years, in powdered formula, was found in company records.

Cronobacter was found at the plant five times in the previous two years, which is normal for a formula maker. The formula was in cans that were ready to be distributed. Abbott didn't recall any of the other batches. The company didn't have to tell the FDA. Abbott said that it had fixed the problem and that it had caused the problem. The inspectors watched as a worker reached into a bag with an essential ingredient without cleaning his hands or gloves. There were pits and cracks where cronobacter could hide, and pooled water where it could grow.

The FDA received a report about an infant in Minnesota who had been hospitalized for three weeks with a cronobacter infection. The baby had been fed a brand of medication. Someone at the FDA told someone at Abbott about the case. The inspectors were never told by the FDA or Abbott. No alarms went off despite the troubling conditions they had seen. There wouldn't be a warning or a recall. The agency used the company to fix the problems on its own.

The complaints continued to come in. An emphasis on productivity sometimes compromised safety, violations of all sorts were hidden, and a culture of permissiveness for some was known to all when a former employee filed a whistle blower report with the FDA. The FDA said that copies of the document were lost in the mail room. Three more infants who had been fed formula were exposed to the disease. A boy in Texas was so close to death that a priest came to give him his final resting place.

Jane doesn't want her son's name to be known and she hasn't spoken publicly about the experience before. A week after he was born, he was sick. He had encephalitis and inflammation in his kidneys. There is damage to the right side of his brain, but it is not yet known how severe it is. He is under the care of an infectious disease doctor. He is now eight months old.

The company failed to prevent the spread and the regulators missed it.

Five different strains of cronobacter were found when inspectors returned to Sturgis at the end of January, four months after their initial visit, three months after the whistle blower's report, and one month after they interviewed him. Abbott detected cronobacter 20 times. Robert Califf, the commissioner of the FDA, told members of the US House of Representatives that the conditions at Sturgis were shocking. There was standing water on the floor and the kids were walking through it with mud on their shoes. Your baby wouldn't want to eat in that kitchen. That's what the inspection showed.

There were 70 million cans and containers of Similac recalled in February. Production ceased in Sturgis. There is a nationwide shortage of powdered infant formula. There are only two other major manufacturers in the industry, and they couldn't make up the loss. The parents panicked because their infants needed the specialty formulas. The shortage continued even after the FDA loosened import restrictions.

The agency received more than 100 complaints about Abbott's formulas. There were seven infants who died and others who were sick with salmonella.

The FDA closed its investigation in May. Evidence doesn't rule out a link between infant deaths and illnesses and the formula produced at the plant The latter is emphasized by Abbott. It says that the strains of cronobacter found in the only two samples available from the infants don't match those found at Sturgis and that no cronobacter was found in two of the three samples that were tested.

Abbot entered a five-year consent decree with the US Department of Justice that gave the FDA extraordinary oversight of the facility. According to a court document, the company and three managers are unwilling or unable to implement sustainable corrective actions to ensure the safety and quality of food.

More than two dozen families have filed lawsuits against Abbott. Abbott sympathizes with the families, but believes the suits are not merited. The FDA is being investigated by the Office of Inspector General. The company failed to prevent the spread of a pathogen that has been known for decades to endanger infants and the regulators missed it.

The city is located on the border with Indiana. It used to be dependent on the railroads and is now home to several manufacturers. The infant formula recipe from Harvard and Boston was sold to Moores & Ross Milk Co. By the late 1940s it was the most popular infant formula in the United States. M&R was offered 11 acres of vacant land for $3,000. In 1949, the company began to produce Similac.

A strain of cronobacter was isolated in a tin of milk. Doctors reported finding it in sick patients who had been fed powdered formula.

Cronobacter cells are motile and rod shaped. They can be found in a lot of things, but dried milk and powdered infant formula are their favorite hiding places. The cells can live for up to two years. The water for the tea has been boiled, the flour has been baked, and the immune systems of people with cronobacter offer protection. Adults can get sick with infections of the bladder. When babies are exposed to cronobacter, their immune systems are immature and their stomachs are vulnerable. The cronobacter will be stimulated by the water that has not been boiled. In 20 minutes, the cells can double in size. They can cause damage to the brain by escaping the stomach. If an infant develops an infectious disease, it can take half the time to die. The Titan of Greek myth devoured his children as they were born and Cronobacter was named after him.

In 1964, when Abbott bought the infant formula facility, it became a large employer in the town. The one with the most prominent name is Abbott, which is the largest taxpayer in the town. It is possible to meet and divorce two spouses, to have your new partners and ex- partners as colleagues, to have children, siblings, and in-laws at the plant. Abbott has employed multiple generations of one family.

Over four months, we contacted more than 80 people. Some retired people were surprised by the trouble at the plant, others didn't believe it or blamed the FDA. Most didn't want to talk about it, and people who'd left seemed afraid of repercussions if they did. They didn't want anyone to notice them.

When they were hired, the goal was for them to stay until they retired. People who worked at Abbott say that they worked hard and the company treated them well. Abbott offered good wages, a 401(k), health insurance, even stock grants for some, and it expected people to work seven days a week to keep the production lines moving. An employee was asked to work extra hours on his final days on the job. The man did. He said he thought he owed them that. Everyone knows the importance of their work.

cronobacter caught the attention of the food safety regulators in 2001, five decades after it was discovered. An 11-day-old boy, born premature and weighing less than 3 pounds, fell ill with cronobacter at a hospital in Tennessee. He had a fast heart rate and a high temperature. He died nine days after his brain stopped working. Three of the eight infants in the unit recovered from their infections. One of the most common sources of nutrition for infants was Portagen. 17,000 cans of the formula were recalled almost a year after the baby died. There is no way to make powdered formula sterile. It is more expensive than liquid formula.

The agency collected samples from different manufacturers to assess the risks. Low levels of cronobacter were found in five of the 22 people. The officials briefed doctors about the new pathogen. An FDA official said that you can always design something better. We are required to raise the bar when things happen. Would we have life preservers on cruises if it weren't for the Titanic? The agency was thought to be overreacting because of the infections of cronobacter.

Cronobacter infections are uncommon. They are not usually identified or reported. Minnesota is the only state that requires doctors to report patients with infections. Four to six infants are sick by cronobacter every year, but some researchers think as many as 18 may be. Three cases have been identified in Minnesota in the last five years.

The agency began negotiations with manufacturers about a testing protocol for cronobacter after the 2003 meeting. The former employees recalled how relieved they were that public scrutiny fell first on a competitor.

There was a different problem in 2010. There were pictures of a trail of flour beetles in a can of formula shown to the meeting. A former employee says that they didn't think it came from the plant. A few of us thought it could have. In some cases, beetles had been there as far back as 2007, according to the FDA. One former employee said it should have been addressed immediately. It's a long way away from Chicago. I think they wanted to keep it at Sturgis.

The company stopped production after recalling 5 million containers of the drug. The FDA said there was no immediate health risk for infants, but they could refuse to eat if they were bothered by insects. A former employee says it was horrible and upsetting. It wasn'tbacteria, but it was something else. Everyone was going to survive.

bushes were removed, the windows were replaced, and the facility was steamed, cleaned, and scrubbed. People were not allowed to prop open doors. The chief executive reprimanded some of the employees. The plant manager stayed with the company.

The cost of the recall is 100 million dollars. In six months, it was once again the top selling formula in the US.

Investigations rarely conclude with a definitive link to Cronobacter. The deaths of two infants who had been fed Enfamil happened in 2011. Walmart was the first to stop selling the formula. Enfamil was put back on the shelves after the FDA said it couldn't be certain of the source of the pathogen. The agency reported that cronobacter was found in the plant of Mead Johnson in Michigan. The FDA didn't push for a recall because it didn't believe the product was in the US The cause of consumer illness has not been determined since the early 2000s, according to a spokesman for the company.

It can be difficult to prove that a can of formula came from a factory. There could be more than one strain of cronobacter in the facility. It is possible that some may be temporary. Some may have settled in a place where they can avoid detection. It is possible to find a strain in a factory and a sick baby in the formula. It is possible that the matching strain existed in the factory but no one found it. The professor says that the two pieces of the puzzle don't connect.

Even though the baby got sick, a sample test could be negative. Not every grain will be contaminated with powdered formula. Cronobacter doesn't affect cans in the same way. It might be in the top or the bottom. It's like looking for a needle in a haystack when searching for the bacterium.

He got a good recommendation from a previous job at Monsanto Co., and was hired as a contractor and moved to the quality assurance department. He kept a positive attitude according to his annual performance reviews. He was rated the "best in Abbott" twice. His supervisor wrote that he was not afraid to step forward and raise concerns in order to keep quality high. He helped the plant win an award. She said he should improve his communication skills because of a series of accusatory emails.

The lawyer for the whistle blower refused to comment on the article. Many know who he is. A retired worker said to look at his back. Abbott says he is a disgruntled former employee who has continued a pattern of ever-evolving, ever-increasing allegations that are not related to the FDA's inspection observations.

His complaint to the FDA was released by Representative DeLauro, who was a strong critic of the agency. His Michigan Occupational Safety and Health Administration file, which includes email exchanges, his annual reviews and other personnel records, witness statements, and the company's defense were obtained through a public records request. He doesn't mention cronobacter, but he talks about the conditions that could allow it to occur there.

He claims that meeting metrics often took precedence over product safety, and that managers would exaggerate the severity of issues to their bosses. The Calcilo XD formula was recalled due to its smell and discolored appearance. The employees were told to check the cans.

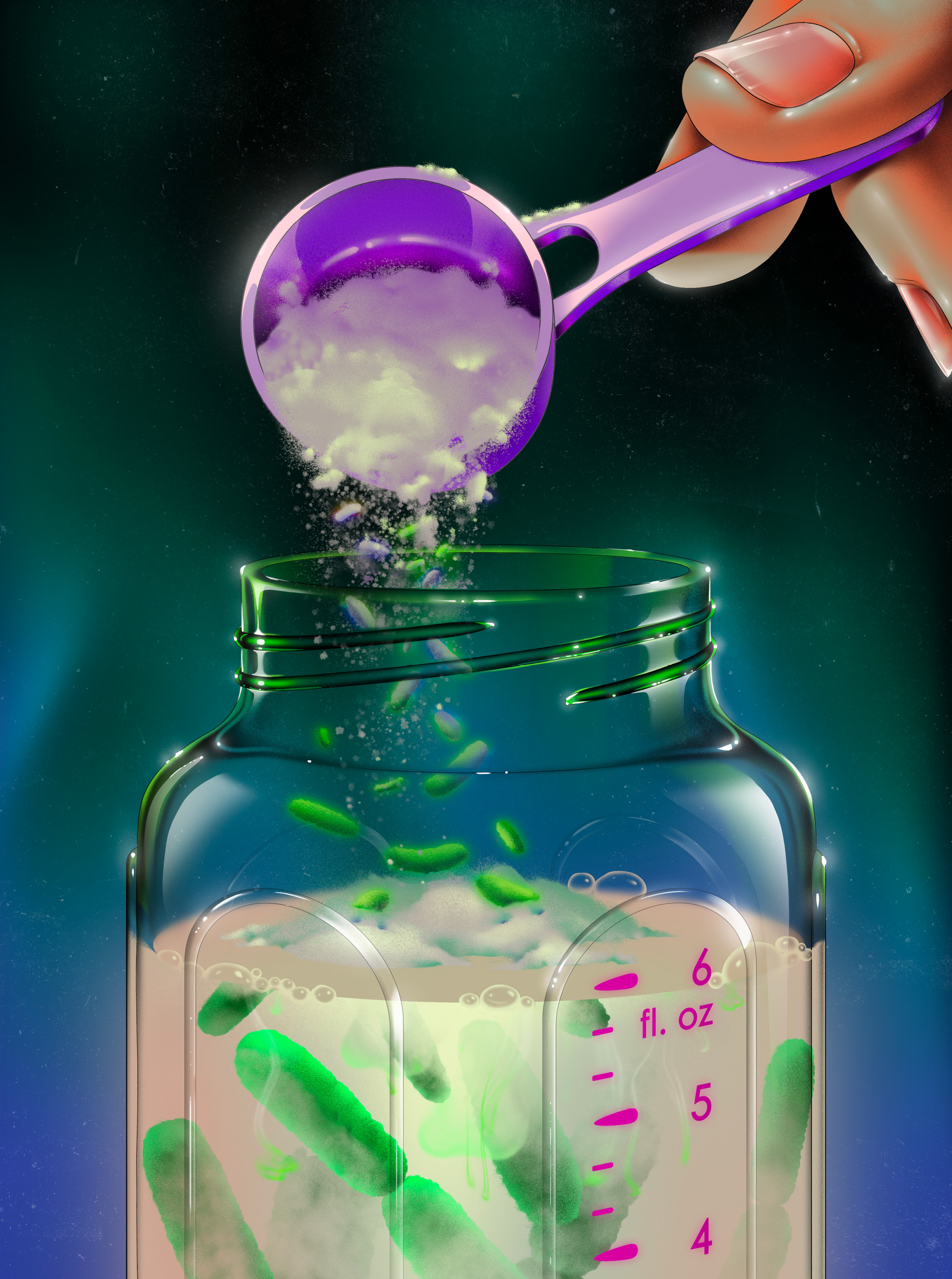

The liquid mix is turned into powder by the dryers in the factory. The formula was blended, Pasteurized, and homogenized before it reached the dryer. It is packaged after leaving the dryer. The formula is most likely to be contaminated when it's inside the dryers. Some of the equipment at Sturgis needed serious repair and had been there for a long time. There were holes in the pipes that allowedbacteria to enter and lead tobacteria not being adequately cleaned out. It could be picked up by the formula that flowed through these pipes.

Management decided that it was no longer necessary to have an engineer look at certain cleaning processes. A contract worker would be able to look over them. He blames the worker's inexperience for missing a brief electrical outage that caused cleaning equipment to malfunction, which resulted in it being covered in caked-on moldy formula.

Several samples of the final formula were found to be contaminated with organisms. Managers didn't want to destroy everything. He says that employees were told to discard cans only if they were produced within a certain period of time. He says that the managers didn't want to lose more than they had lost.

The FDA didn't mention the incident in its report A supervisor admitted it had been awkward to avoid answering inspectors' questions after staff and managers applauded one another on making it through the audit. A sample of Alimentum was positive for cronobacter the month before. The batches hadn't been released and were going to be destroyed. The FDA left it at that after Abbott said it had found the source, sanitized the areas, and resumed production.

These concerns weren't the cause of the conflict between the management and the whistle blower. On Friday, May 29, 2020, he sent an email to plant supervisors that said he believed X brought a stun gun to work. It sounded like a person had been killed.

A woman had a stun gun. Her husband picked up the weapon after coming to the plant. He thought his colleague was protected by her friendship with the Big Three. She was part of a group of people. The man was not. He called Employee Relations on Monday. Some considered that a violation. The employee said that management doesn't want people to do that because they don't want him to.

He made two mistakes during the summer. He made a second one. He said it was because he didn't have enough training. The facility managers said he put the company at risk of a recall and fired him.

He claimed that he was retaliated against by the Occupational Safety and Health Administration. He filed a federal OSHA claim five months later. The FDA and Abbott were the first to receive the complaint from OSHA. Instead of waiting until the annual one in September, the agency could have scheduled an inspection. It says it is looking at its reply.

The state of Michigan dismissed his claim of retaliation. He told the FDA that if employees could speak freely, they would be like a house of cards.

Our baby was on the recalled formula and it was just bad luck. I didn't think that was right.

The FDA followed protocol when they saw reports of cronobacter in Abbott. The previous inspection hadn't turned up any egregious violations so they relied on the company's records to do the dirty work.

In October the FDA received a complaint by email, but copies of the email were lost in the mail room. The people who read it didn't give it to them. The standard procedure was not to escalate. Stephen Ostroff is a former senior FDA official. The director of food policy for Consumer Reports says that it should have been obvious that this was more than a vendetta. Everyone at the FDA should have been aware of it. Representative De Lauro was not surprised that it didn't. She thinks that the agency doesn't want to be a regulatory agency. They usually support the industry over the individual.

The whistle blower was not interviewed until late December when three inspectors arranged a three hour video call. Abbott was contacted soon after to schedule a visit. Abbott requires employees to bevaccinated against Covid, tests them weekly, and has a lower incidence of infections than the surrounding area. The company told the inspectors to wait because of the outbreak.

The inspectors said they couldn't wait any more. They discovered cronobacter when they went to the town. Contract workers repairing the roof were the ones who brought in thebacteria. There are pits and cracks in the dryer towers. Water was in equipment that should have been dry. There were over 300 problems with water in the past two years, many of which were blamed on a roof that needed to be fixed.

Abbott didn't announce a recall despite being urged by the FDA. Abbott issued a voluntary recall after the FDA issued a consumer advisory. The company expanded it within 11 days.

Owen was in a hospital when he was 5 months old. He vomited and had a temperature of 104F. His mother says that he wasn't responding very well to anything. Owen was having a seizure according to the doctors. The man wasn't shaking. His father said that he was stiff. His body was locked in.

Owen would have to go to a larger hospital. Medics told the ambulance to take him to the hospital because he wasn't stable. He would have to be taken to the hospital by helicopter. They watched as he was put on a stretcher and put in a helicopter. They couldn't get along with him.

He was put on antibiotics after the doctors suspected he had a disease. They did a tap on the spine to be certain. The seizures were stopped. Owen was wrapped tightly and slept through the night. His parents were told by a doctor that he had a case of the disease. It was a terrible way to describe it. There was nothing I could have done to stop it. It was just kind of happening.

After the Abbott recall was announced, Jordyn didn't hear about cronobacter. She began to wonder. She says that this is a coincidence. Our baby was on the recalled formula and it was just bad luck. I didn't think that was right. She was told that the antibiotics Owen had been given would make it impossible to look for cronobacter.

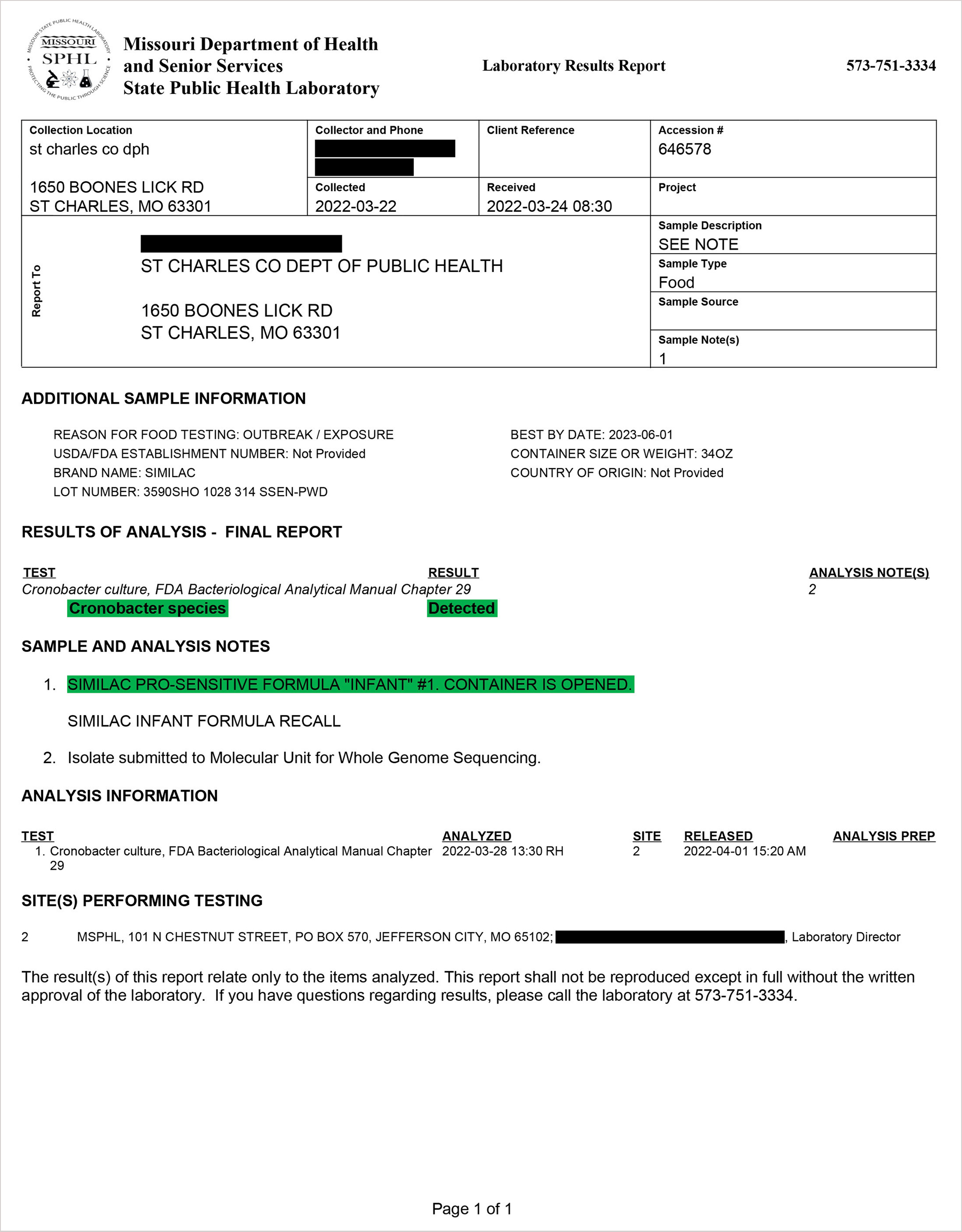

Four cans of recalled formula were brought to the Missouri Department of Health and Senior Services. Cronobacter was found in one of the cans of Similac Pro-Sensitive formula. Owen isn't included in the FDA's official count because he wasn't tested for cronobacter.

Owen is hungry and bright on a mid- May afternoon. He eats Abbott's liquid formula. He rolled from his belly to his back as he crawled. The man has two teeth. They know that they are lucky but they don't know how long that will last. She says that he could have mental delays, physical delays, learning disabilities, and other things that are not known for a while. We are supposed to be on the look out. I ask myself if that is normal.

Abbott has a commanding position in infant formula due to government intervention. Half of the babies born in the US each year are provided with powdered formula by the Special Supplemental Nutrition Program for Women, Infants, and Children. A contract is entered with a single manufacturer. Thirty five states and the District of Columbia have deals with Abbott.

The companies give the states a large amount of money. Texas bought Abbott's standard powdered infant formulas for $10 million last year. Private mommies, as they are called, often buy the same brand from the same store because of the guaranteed sales.

Every US state has a contract with one manufacturer to make formula for the Special Supplemental Nutrition Program for Women, infants, and Children. Abbott has a lot of contracts.

The USDA has a food and nutrition service.

US Secretary of Agriculture Tom Vilsack wrote Abbott in May expressing grave concern that it hadn't promised to give refunds for other brands if the shortage continued. At least through October, Abbott will spend $5 million to help families who rely on EleCare, a program for infants with food allergies.

In May the company put out a definitive statement about the FDA's investigation: "The formula from this plant did not cause these infant illnesses" Some experts didn't like that. They can't say that Craig Hedberg is an epidemiologist at the University of Minnesota. The former FDA official said he was unimpressed with their argument. If it looks like a duck and quacks like a duck, it's probably a duck. More than 10,000 cans of formula have been tested and no cronobacter has been found.

The decree was made public. Before it could start up again, the FDA had to improve its safety procedures, repair its equipment, replace the roof, and redo the floors. Bill Marler, a food safety lawyer, says that the consent decree is an admission that you could be indicted quickly. If you're producing food in unsanitary conditions, you're stuck. According to Abbott, the consent decree is a civil agreement and that it chose not to challenge the allegations in the document so it could restart production quickly.

Jane is one of the parents who have sued Abbott. It is possible that the Bayers will join them. The food division of the FDA needs to be separated from the FDA in order to hold it to account. In addition to its internal review, the FDA arranges for an external one. It is rethinking its inspection protocols about when to take its own samples. The FDA emphasizes the importance of a company's quality systems and culture. When problems are found it is the responsibility of the firm to fix them. An Abbott spokesman says thatSturgis employees are committed to quality and safety and are determined to re-earn the trust of parents.

Less than two weeks after the factory opened, a storm blew through town. Production was stopped after the plant flooded. Since early July, the company has been making EleCare. 180 cans from each batches will be tested for cronobacter. If it is detected, everything must stop and the company must tell the FDA if the pathogen has returned.