Wooden objects can be carved, bent or pressed. That's not new. Scientists will describe how a 3D printer can be used to create wooden shapes. In the future, this technique could be used to make furniture or other wooden products that could be shipped to a destination and dried to form a final shape.

At the fall meeting of the American Chemical Society, the researchers will present their findings.

Plants and animals can change their appearance. As the wood dries, it can change into different shapes. The wood shrinks and warps because of different fiber orientations. "Warping can be an obstacle, but we thought we could try to understand this phenomenon and harness it into a desirable morphing," says Doron Kam, who is presenting the work at the meeting.

Eran Sharon is one of the project's principal investigators. Scientists have begun printing flat sheets that can form themselves into 3D shapes after a change in temperature or humidity. Synthetic materials were used to make the self- morphing sheets.

Sharon said they wanted to go back to nature and do it with wood. He and Kam are two of the principal investigators who took on this challenge.

A few years ago, the team developed a water-based ink composed of wood-waste microparticles, which are natural binders from plants. The researchers used the ink in the printer. The morphing behavior of the printed piece is dictated by the way the ink is laid down.

The team found that the shape of the object can be adjusted. The degree of alignment of the wood fibers is affected by the print speed and the amount of ink used. Shrinking occurs in all directions because of a slower rate. Shrinkage is more direct because of the faster printing.

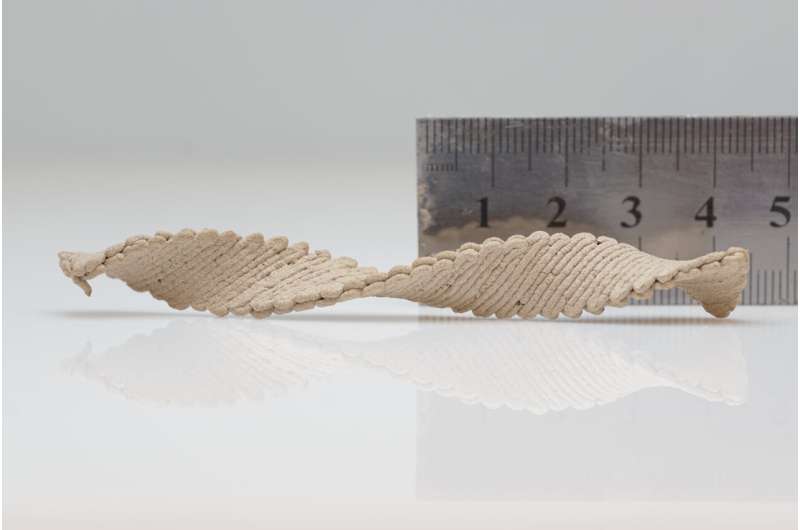

Scientists learned how to program the print speed and pathway. They found a way to make a helix after drying. They were able to program the printing pathway, speed and stacking to control the direction of shape change, such as whether a helix spirals clockwise or counterclockwise.

The team will be able to combine the saddles, domes, helices and other design motifs to create objects with complicated final shapes. Kam believes that it could be possible to make wood products that are shipped flat to the end user. The object could warp at the destination. It could be possible to license the technology for home use so consumers could design and print their own wooden objects with a regular 3D printer.

The morphing process could possibly be reversed. Sharon wants to show that we can change the shape of an object under certain conditions.

More information: Wood warping by 3D printing, ACS Fall 2022. www.acs.org/content/acs/en/mee … tings/fall-2022.html Citation: Your next wooden chair could arrive flat, then dry into a 3D shape (2022, August 23) retrieved 23 August 2022 from https://phys.org/news/2022-08-wooden-chair-flat-3d.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.