Several space agencies and commercial space partners will send crewed missions to the moon within the next decade. These missions are intended to create a sustained program of lunar exploration. Infrastructure needs to be created in order for us to stay on the Moon. Food, water, and power systems are included. Local resources can be used to meet these needs.

In-situ resource utilization is a process that reduces costs by limiting the number of missions that need to be carried out. It may be possible for astronauts to produce solar cells using locally-sourced regolith, or moon dust, in order to create a promising material known as pyrite. The findings could be a game-changer for missions in the near future, which include the European Space Agency's Moon Village, NASA's Artemis Program, and the Sino-Russian International lunar Research Station.

Ktriin Kristmann is a researcher at TalTech and the communications lead for theESTCube. Advenit Makaya is an advanced manufacturing engineer with the European Space Research and Technology Centre. The Moon has elements that can be used to create monograin layer solar cells.

The ability to generate power in a way that is not dependent on Earth is a need for future lunar missions according to Kristmann. Focus on renewable sources and rely on batteries of fuel cells only as a backup. As Kristmann said.

If we want to establish a permanent settlement on the moon, we need to be able to produce power there. Most of the conventional energy sources available on Earth are not available on the Moon. The main challenge is to use the resources that are available on site from the lunar regolith to build the energy station.

Kristmann and her colleagues at TalTech have been working with pyrite for a long time because of its potential as a solar cell Substrate. The material is made from microcrystalline powders and has a lightweight and flexible cell. Pyrite has an iron atom with two sulfur atoms that are abundant on the lunar surface.

Marit Kauk-Kuusik, the head of the photovoltaic materials lab at TalTech and co-author on the study, explained the benefits of the material in an article published by TalTech.

Scientists at TalTech have been working on solar cell technology for a long time. The light absorbing layer made of the single-crystalline powder contains abundant and low-cost elements. This technology will bring innovation to the solar power field.

Kristmann and her colleagues designed a solar cell structure that consists of a pyrite absorber layer with a layer of NiO and TCO They would be combined with some of the other things. Many advantages are presented by the inclusion of this material.

Pyrite is an advantage because the energy input that goes into producing a Pyrite-based solar panel is very low. The preparation of this material solar cells can be done at a lower temperature. The lower the temperature, the lower the costs. Iron and sulfur are not hazardous for humans.

The team used the liquid salt synthesis method to combine iron and sulfur in a solution that was heated to 740 C. The solution was slowly reduced to a temperature of 1067 F and then quickly cooled to room temperature, which produced a single-phase monograin powder. Space agencies are planning to send to the Moon, and these tiny crystals can be made into MGLs using 3-D printers.

At the end of the reaction, the salt was removed by washing. The process can be adjusted to the Moon environment as it doesn't use any complicated equipment with difficult to obtain prerequisites such as high purity vacuum chambers or strong lasers.

The work builds on previous work by Kristmann and other researchers. Taltech has been researching MGL solar cells for a long time. The production process makes high-efficiency singlecrystalline solar cells that are flexible and thin, making them valuable for the growing renewable energy market. It is the potential for providing renewable energy for astronauts on the Moon that motivates Kristmann's team to find better energy solutions.

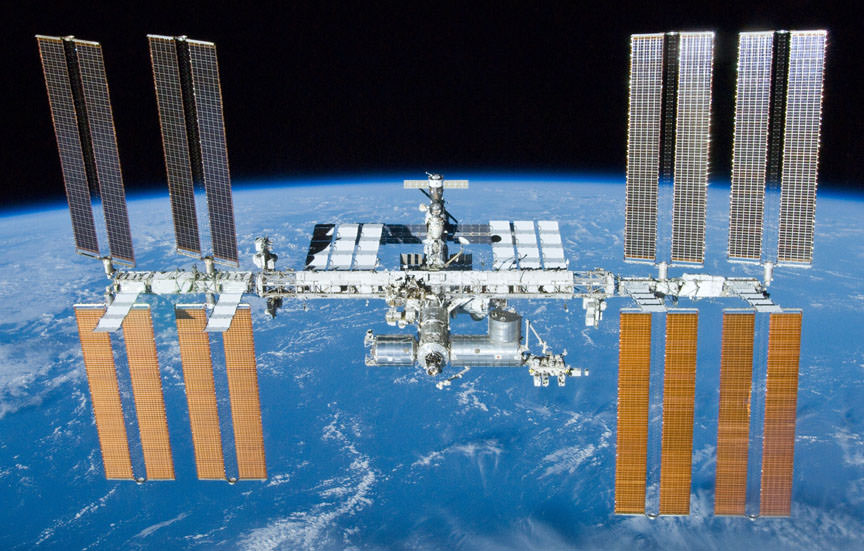

The European Space Agency wants to create a lunar habitat called the Moon Village. The International Space Station will be a spiritual successor to this base, where astronauts from around the world will live and work for months at a time. The European Space Agency became interested in TalTech's photovoltaic research about six years ago when they looked into MGL solar cell technology.

Advenit Makaya has worked with Kristmann and her colleagues. He has supported the development of promising advanced materials and processes for space applications for a long time. He sent an email to Universe Today.

“The requirements of power systems to support lunar exploration depend on the volume of activities performed at the surface and the time of the missions. Several space agencies and private companies, at the international level, have indicated plans for long duration missions on the lunar surface. This will require power systems which provide enough energy for the range of activities to be conducted, as well as suitable reliability and resistance to the space environment, to provide power for long duration missions.

“Sustainability becomes therefore essential. Solar power has been the traditional source of power for space missions, so far and it is expected to still provide a large share of the energy required in lunar missions. Having the ability to produce the solar cells from local material could increases the sustainability of the missions and help reduce the dependance on supplies from Earth and the associated costs.”

Testing the technology to see if it would work in space was the initial focus of their collaborative efforts. After proving that the technology could operate in the extreme cold and vacuum of the Moon, they decided to use MGL solar cells to power future lunar outposts and how they can be manufactured using lunar regolith. The success of this study shows that it can be done, which will affect future lunar missions. Kristmann said that.

The implications of sustainable energy production are significant. When talking about the lunar settlement, we can focus on other important topics with a reliable energy production method. Reliable solar energy production would allow us to explore a new world without pollution and allow us to learn from our past.

There is also the benefit of enduring self-sufficiency when it comes to long-duration missions. The International Space Station depends on regular shipments of replacement parts and components. Replacement solar cells and electronics are included. The ISRU aspect of MGL solar cells is very attractive because shipments will be less and farther between.

Replacing solar power hardware on long-term exploration missions on the lunar surface will become more relevant due to potential degradation in the lunar environment. It is possible to support maintenance and replacement needs by manufacturing solar cells with in-situ resources.

It can allow for the production of new hardware for further exploration activities. Due to the distance, in-situ manufacturing for maintenance and repair operations becomes essential.

This research has many applications on Earth. By using local resources and providing power in hostile environments, the technology can mature greatly. Methods that ensure sustainable living in space will invariably lead to solutions for sustainable living here at home. Resolving for space will solve for Earth.

Science Direct and TalTech are further reading.