A piece of film can be stretched to reveal something. You can check the arm band's color to see how big the muscles are. You can wear a swimsuit that changes color as you do laps. MIT engineers have brought back a photographic technique that could lead to the creation of such color-changing materials.

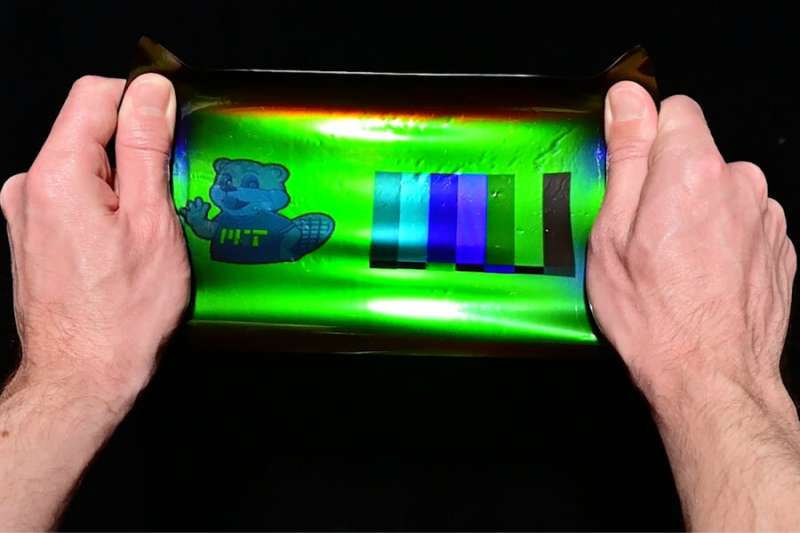

An MIT team has printed large-scale images onto elastic materials that when stretched can transform their color, reflecting different wavelength as the material is strained.

When the films are stretched, the flowers change from warm to cooler shades. They printed films that show the fingerprints of objects such as a strawberry.

The team's results show how to make large-scale materials with structural color, instead of using chemicals or dyes.

Benjamin Miller is a graduate student in the Department of Mechanical Engineering at MIT. Can we use this material to make robot skin that has a human-like sense of touch? Is it possible to make touch-sensitive devices for things like virtual augmented reality? We're looking at a large space.

Nature Materials contains the results of the team. Two of Miller's co-authors are MIT students.

Coincidentally, a hologram happenstance.

Nature inspired materials are developed by the group. The light-reflecting properties of mollusk shells, butterfly wings, and other iridescent organisms have been studied. These structures are designed to reflect light in a similar way to miniature colored mirrors.

A variety of techniques have been used to recreate this natural structural color in materials. Some efforts have produced small samples, while others have produced larger samples, but with less optical precision.

Despite several potential high- impact applications, an approach that offers both microscale control and scaling remains elusive.

Miller went to the MIT Museum to look at an exhibit on holograms, a technique that creates three-dimensional images by superimposing two light beams onto a material.

The same thing nature does with structural color is what they do in holograms.

He read up on Lippmann photography, an early color photography technique invented by Franco-Luxembourgish physicist Gabriel Lippmann, after visiting the museum.

Lippmann created color photos by setting a mirror behind a thin, transparent emulsion. He put the setup in motion by exposing it to a beam of light. The emulsion's grains were stimulated by the incoming and outgoing light waves and reflected the pattern and wavelength of the light.

Lippmann used this technique to projected images of flowers and other scenes onto his emulsions. It took a long time for the material to be exposed to light. The technique faded into the past because of its limitations.

A new twist on the old.

Miller wondered if Lippmann photography could be used to make large-scale, structural colored materials. Light-sensitive molecule that can cross-link to form colored mirrors are found in current holograms.

The chemistries of modern holographic materials are so responsive that it's possible to do this technique on a short timescale.

The team applied elastic, transparent holographic film onto a sheet of aluminum for their study. An off-the-shelf projector was placed several feet from the film and projected images onto each sample.

The films produced large, detailed images within several minutes, rather than days, as they suspected.

After removing the film from the mirror, they stuck it to the black elastic backing. The colors change when the material stretches and thins out because of the structure of the material.

The film is sensitive to strain. They stuck the red film to a silicone backing that ranged in thickness. The film was red in places where the backing was thinner, and blue in places where it was thicker.

They found that pressing various objects into samples of red film left green marks that were caused by things like the seeds of a strawberry and the wrinkling of a fingerprints.

They could project hidden images if they tilted the film at an angle to the incoming light. The material reflected a red-shifted spectrum of light. Green light used during material exposure and development would cause red light to be reflected, and red light exposure would cause structures to reflect a wavelength that is not seen by humans. The otherwise invisible image changes color when it is stretched.

"You could make it sound like a message is being sent in this way."

The technique used by the team is the first to allow large-scale projection of colored materials.

He says that Lippmann's materials wouldn't allow him to make a Speedo. We can make a full leotard now.

Beyond fashion and textiles, the team is looking at applications such as color-changing bandages for use in monitoring bandage pressure levels when treating conditions such as venous ulcers.

More information: Benjamin Harvey Miller et al, Scalable optical manufacture of dynamic structural colour in stretchable materials, Nature Materials (2022). DOI: 10.1038/s41563-022-01318-x Journal information: Nature Materials