Roger Harrabin is an energy and environment analyst for the British Broadcasting Corporation.

A lot of planet-warming carbon dioxide is created during the manufacture of many key materials. New low-carbon technologies are being explored by Roger Harrabin. Artists are assisting him in telling the story.

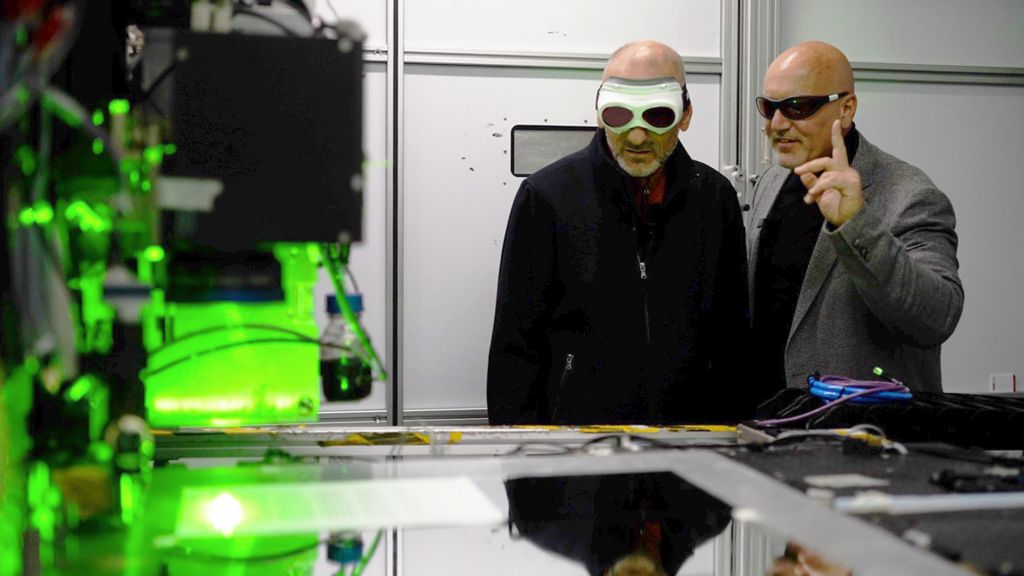

Scientists have come up with a way to suck the ink off the printer paper so it can be used multiple times.

They want to reduce demand for office paper in order to cut carbon dioxide emissions.

Special coated paper stops ink from soaking into the page. The ink is Vaporised by a powerful Laser.

Barak Yekutiely described it as circular printing.

He says that if we care about the planet, we need to stop cutting down trees.

The de-printer can remove ink from paper.

The invention is used in a documentary. The Art of Cutting Carbon is my last film for the British Broadcasting Corporation after 35 years of reporting the environment.

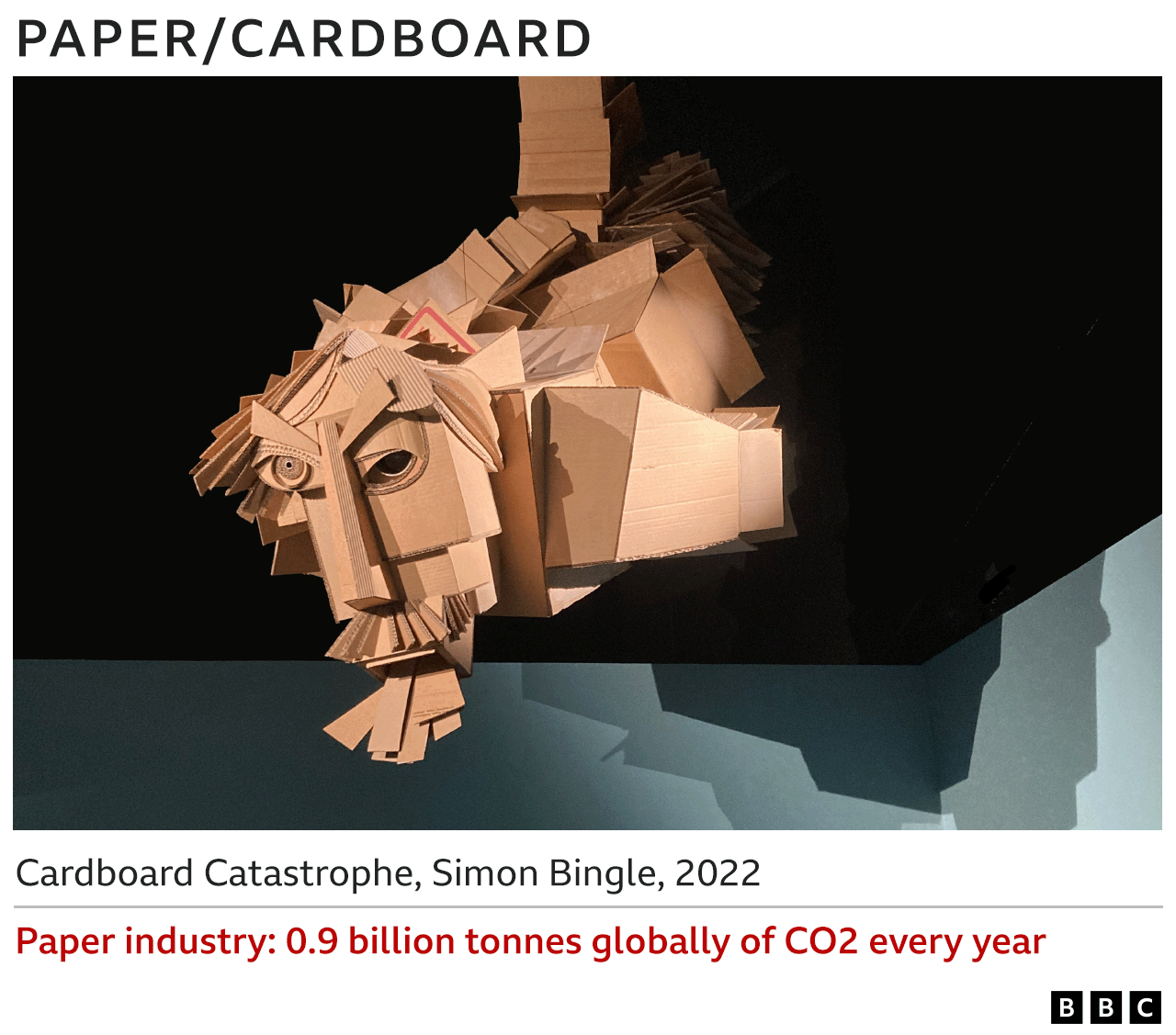

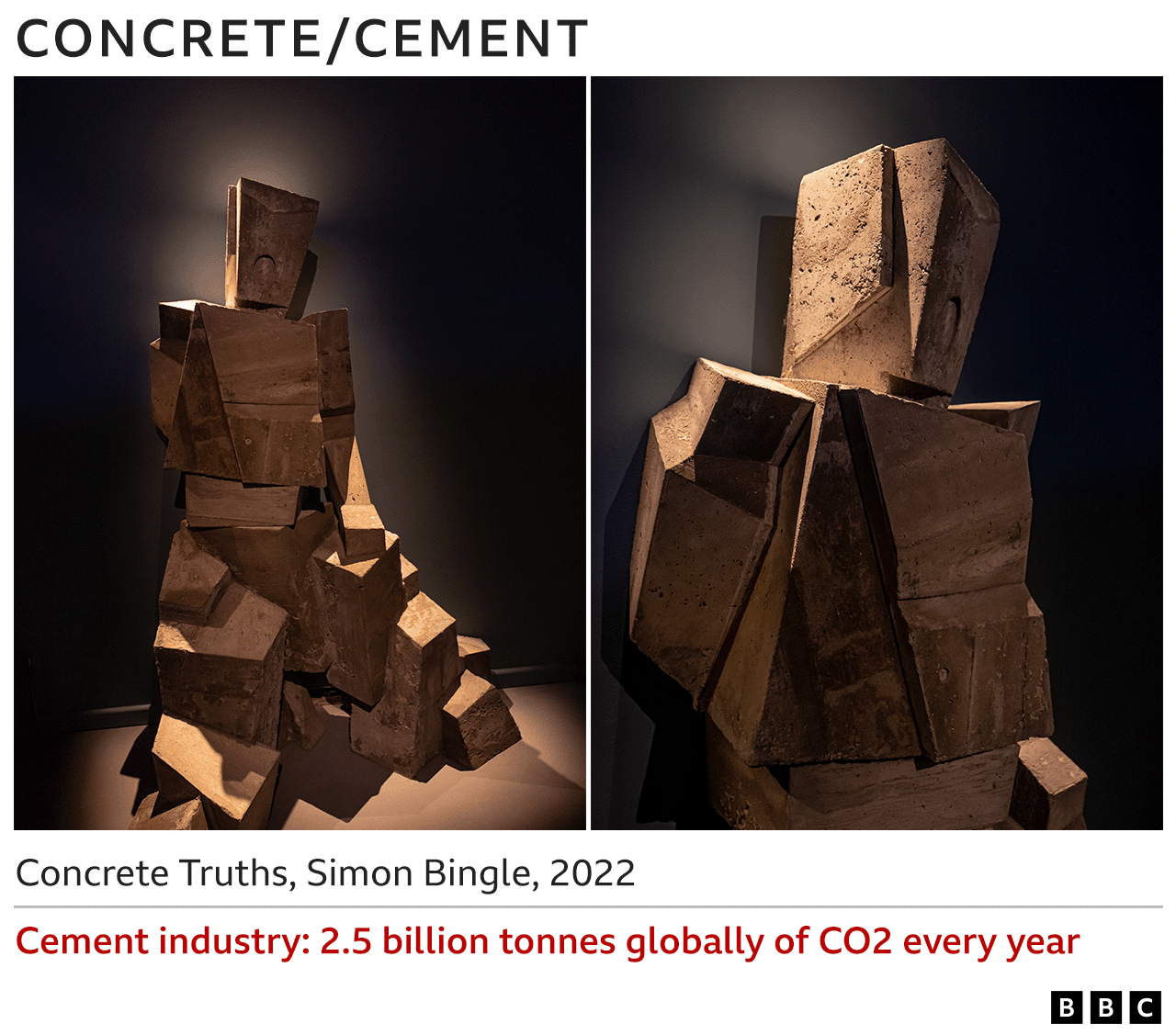

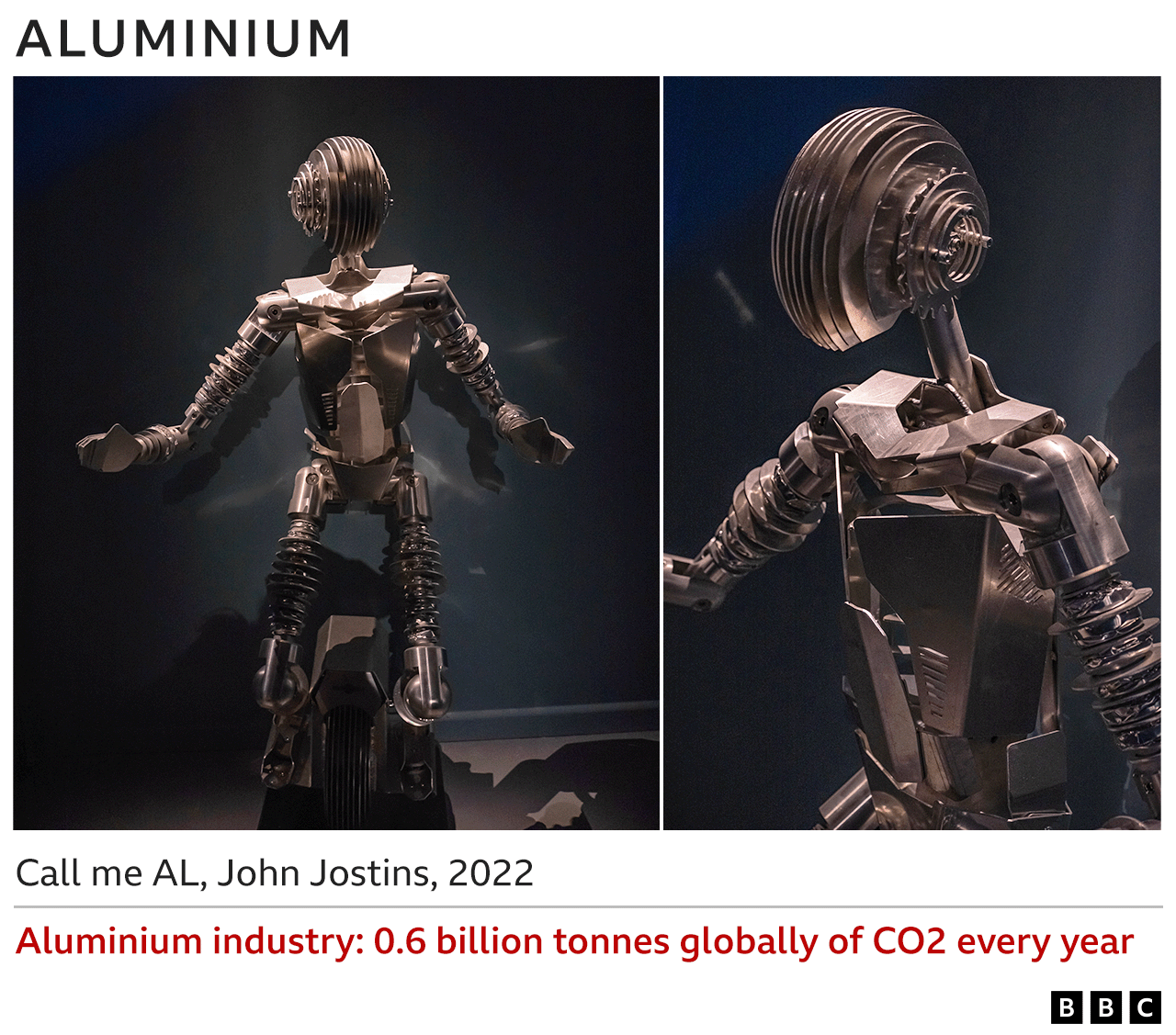

To highlight the huge amounts of planet-heating CO2 produced globally from manufacturing these everyday materials, I have created sculptures in steel, cement, plastic, aluminum and paper.

British artists work with a variety of materials, including concrete, steel, aluminum, plastic and cardboard.

More CO2 is created by hidden emissions than all the world's planes, trains, cars, ships and trucks put together.

New technologies that limit the amount of CO2 produced can be used to tackle emissions. The other is to use less.

The de-printer is part of a lot of innovation.

An example of how to take CO2 out of steel manufacturing can be found in Northern Sweden. The entire Indian economy emits roughly the same amount of gas per year as the industry does.

Normally, making steel involves mixing iron-bearing rock with coke and super- heating it at 1,500C.

The iron is turned into a steel by the heat. The process makes more carbon dioxide than it does steel.

SSAB, a multinational steel manufacturer, has found a way to stop the creation of CO2.

The first thing to do is to use renewable power, such as wind turbine or hydro electricity, instead of coal. The second step is to replace hydrogen with coke.

The reaction with hydrogen and iron produces only water.

The steel makers are turning down new orders because of high demand for the world's first zero- carbon steel production.

2.5 billion tons of CO2 is produced by the cement industry annually. The structures in our lives are formed from cement.

Clouds of CO2 are created when limestone is heated. The heat can be provided by coal or gas.

Big players in the industry want to be carbon neutral by the year 2050 and are experimenting with other binding materials that don't need to be cooked in the same way.

We can't wait to tackle climate change, so the rail firm is building a Viaduct made from a sandwich of cement and steel.

The smart design allows less material to be used by exploiting the different physical properties of the cement and steel in a way that's catching on quickly. The engineers say this innovation cuts materials costs and halves the CO2 emissions that would have been seen in a more traditional construction

HS2

HS2Taking a decision not to build the controversial route would have saved a lot of emissions.

Engineers are trying to squeeze more out of infrastructure that already exists by using refurbished buildings instead of using cement to build replacements.

The plastic industry is one of the worst offenders. The majority of the world's plastic is derived from fossil fuels.

In the Netherlands, a bio-chemical firm is claiming to be the first to use a plant-based plastic to make a bottle.

The new product is called PEF and it's said to produce a third less emissions than the previous one.

wheat and corn are the raw materials. It's similar to eating sugar.

There is a lot of enthusiasm about this breakthrough.

bioplastics come from a very low base. They make up a small portion of the plastics industry.

Competition for the land used to grow the raw materials for PEF bottles will increase as farmers attempt to feed people in a future world of deadly heatwaves.

Governments are lagging behind the pace of climate change even though the United Nations has promised a treaty to limit the making of plastic.

Though it produces less CO2 than cement or steel, aluminum is the last main emitter.

Major firms have located where renewable power is plentiful and cheap, in places such asIceland, because of the huge amount of energy needed to produce aluminum from bauxite rock.

More than 85% of the metal is recycled because it is so valuable. They are resurrecting an invention that has been around for more than 100 years.

At a fraction of the emissions of normal recycling, it's a machine that takes in aluminum chips, warms them, and compressions them to make a tube of re-formed aluminum.

Firms are being helped by innovations like this. The inventions are not fast enough to meet the goal of halving CO2 by the year 2030.

The shortage of clean electricity from renewable sources is the biggest problem for these industries.

"So many of us would like to have a solution based on inventing a new technology," says Prof Allwood. It's not the problem.

The speed at which we can scale up is the most important thing. It's not possible to bring out a new phone and sell it quickly but it is possible to do things differently, so the solutions we need have to be based on technologies that already exist.

Paper, steel, cement, plastic and aluminum have been made in high volumes and have been so cheap that they have been wasted.

Prof Allwood is optimistic that we can calm climate change, but warns that in the future we need to use less material.