A new material created at Cornell shows a promising new approach to mimicking natural tissue.

A new strategy for synthesizing clinical solutions for damaged tissue was provided by the results.

It's important that tissue is soft enough to bend and flex, but also durable enough to hold up over time. When tissue wears out or is damaged, synthetic materials have the potential to serve as replacements, but they don't possess the right combination of biological and mechanical properties.

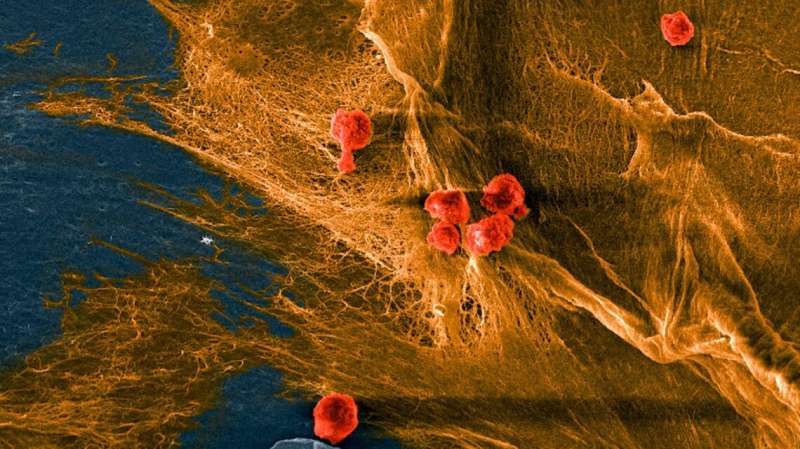

Cornell researchers have created a bio hybrid material that is similar to a natural tissue. The material is made up of two main ingredients, one of which is a synthetic zwitterionic hydrogel.

"These charge groups interact with the negatively and positively charged groups in the collagen, and this interaction is what enables the materials to dissipate energy and achieve high levels of toughness," said Lawrence Bonassar.

The bio hybrid is 40% more elastic and 11 times more durable than the zwitterionic material alone.

The biocompatibility of the material means it can recruit cells and keep them alive, according to the co-lead author of the study.

A piece of scaffold that can tolerate some initial loads until the tissue fully regenerates is one of the things we want to make. You could 3D print a porous scaffold with cells that could eventually create tissue around it.

In addition, the bio hybrid material is self-assembling once the two ingredients are mixed, which creates the same network ofCollagen seen in Natural Cartilage, which otherwise would be hard to produce.

Four research labs were brought together by the research. The co-author of the study, Robert Shepherd, an associate professor in the Sibley School, and the Walter R. Read Professor, developed the zwitterionic hydrogel, which was already under development in Bonassar's laboratory.

The material and the processes behind its synthesis are being researched by the authors. The material is suitable for bioprinting, and the authors have begun experimenting with using it as a 3D-printer.

More information: Cameron Darkes-Burkey et al, Simple synthesis of soft, tough, and cytocompatible biohybrid composites, Proceedings of the National Academy of Sciences (2022). DOI: 10.1073/pnas.2116675119 Journal information: Proceedings of the National Academy of Sciences