By turning a traditional lab-based fabrication process upside down, researchers at Duke University have greatly expanded the abilities of light-manipulating metasurfaces.

The combination could allow these devices to be used in a wide range of practical applications, such as cameras that capture images in a broad spectrum of light.

The results can be found in the journal.

It is possible to trap the energy of light in groups of electrons on a metal surface. The field created by this creates a powerful one.

The plasmons have been excited on the surface of metal. The system can be changed to absorb specific wavelengths of light by controlling the size of the cubes and their spacing from each other.

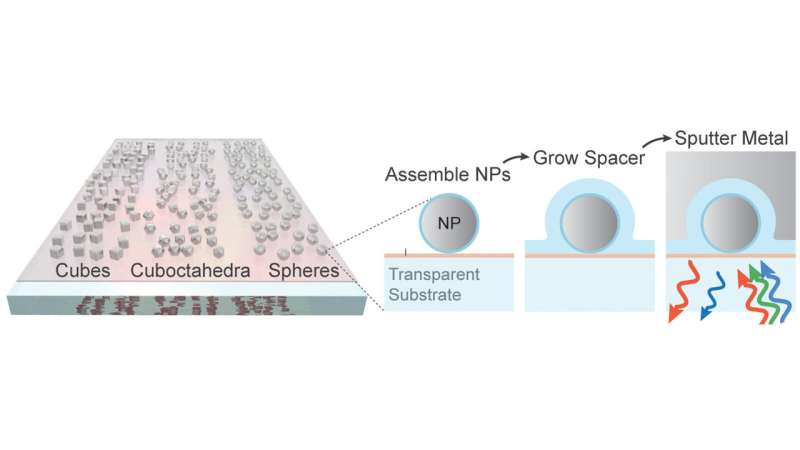

The plasmonic meta surface consists of three layers, each with a metal base coated in a nanometer-thin transparent substrates. The configuration works well for lab demonstrations, but leaves little room for creativity. Researchers couldn't use a wide variety of shapes because the area of the nanoparticles must be within a few nanometers.

To get around the need for flatness, Maiken Mikkelsen, the James N. and Elizabeth H. Barton Associate Professor of Electrical and Computer Engineering at Duke, and her team decided to put each nanoparticle in its own hole. This would allow plasmons to reside on the sides and bottoms of the lower half of the nanoparticles. This is not easy because of the tight tolerances.

"We need to control certain dimensions with single-nanometer precision over the surface of a centimeters-sized wafer." It's similar to trying to control the thickness of the grass on a football field.

The traditional fabrication process was flipped upside down. Instead of starting with a metal surface and putting a thin transparent substrate on top, they start with the nanocubes, which are covered with a thin spacer coating that follows the underlying shape, and then top off with a metal coating. It is similar to a pineapple upside-down cake, where the pineapples are covered in caramelized sugar and baked into a thin bottom.

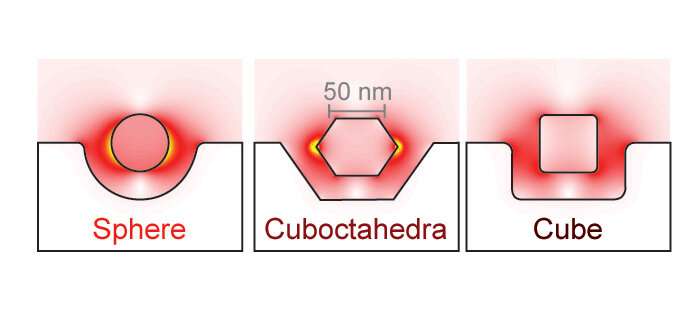

Mikkelsen and her colleagues could experiment with new shapes with plasmons trapped between gaps. The team tried out a number of different shapes in the paper.

It's difficult to synthesise nanoparticles and there are limitations for each shape. We can explore a variety of metals by using almost all shapes.

The test results show that the new fabrication method can match or exceed the capabilities of previous methods, as well as expand the range of frequencies that are harnessed by using different shapes and metals. The variations change where the nanoparticles capture energy. The new technique could potentially expand the use of the technology into driving chemical reactions or thermal detectors.

A "super camera" that can capture and process a wide range of light's properties is Mikkelsen's first priority.

Large areas can be covered by the metasurfaces very cheaply, as we use entirely lithography-free fabrication techniques. New plasmonic metasurface applications can be inspired by the integration of the metasurfaces with other technologies.

More information: Jon W. Stewart et al, Control of Nanoscale Heat Generation with Lithography-Free Metasurface Absorbers, Nano Letters (2022). DOI: 10.1021/acs.nanolett.2c00761 Journal information: Nano Letters