For now, copper is the king. Pacific Northwest National Laboratory is working on a recipe that will make aluminum economically competitive with copper. If fully realized, this research could lead to an ultra-conductive aluminum alternative to copper that would be useful in markets beyond transmission lines.

If you could make aluminum more conductive, what would it look like? "Replacing copper with more conductive aluminum would make a huge difference because it would be lighter, cheaper, and more abundant." We're trying to solve that problem.

Both copper and aluminum are made of metal.

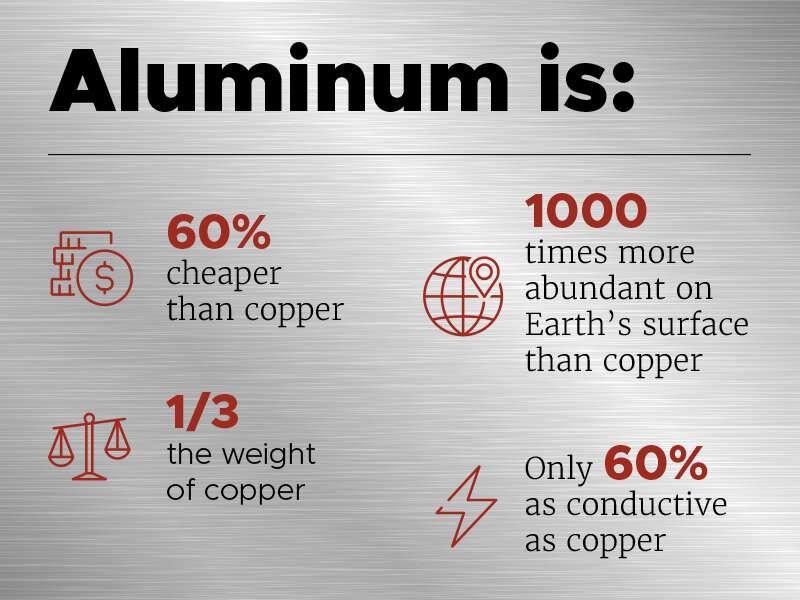

The price of copper is going up because it is out of stock. There is no escaping the fact that copper is becoming less available and more expensive as it is used in everything from handheld electronics to underwater transmission cables. The rising number of electric vehicles is expected to cause these challenges to get worse. EV efficiency is adversely affected by copper.

The price and weight of aluminum is less than the price and weight of copper. It can be a limitation in some real-world applications.

"Conductivity is important because a lighter weight wire can be used to design lighter motors and other electrical components so your vehicle can potentially go longer distances." Everything from a car's electronics to energy generation to the grid to charge your car's battery can all become more efficient.

It would be a game-changer if aluminum'sConductivity was increased.

We thought metals couldn't be made more transparent. "That's not the case." If you change the structure of the metal you can affect its properties.

To begin figuring out how much aluminum conductivity could be increased, a group of people, including a professor and a graduate student, collaborated.

A successful model.

The researchers had to come up with something new because this type of simulation had never been done for metals. They looked to the material for inspiration because previous research had shown that it was possible to conduct electricity in it. The team adapted these concepts to work with aluminum, so that they could see what would happen if atoms were removed or rearranged. The changes added up to a big gain.

Even the team was surprised by the model's ability to mimic real world conditions. "We didn't think it would be this close to reality," said Kappagantula. The model simulation that's based on the atomic structure and its different states is so precise that I was amazed. It's great.

The researchers want to see how much they can increase the conductivity of aluminum in the laboratory by following a theoretical recipe. Increasing the conductivity of other metals using the same simulations is being explored.

Any application that uses electricity or copper could benefit from the development of affordable, lightweight, ultra-conductive aluminum.

More information: Kashi N. Subedi et al, Electrical conduction processes in aluminum: Defects and phonons, Physical Review B (2022). DOI: 10.1103/PhysRevB.105.104114 Journal information: Physical Review B