The Rice University team has simplified handling of the highly valuable nanotubes to make them more suitable for large scale applications.

The researchers reported in Nature Communications that they were able to assemble themselves into liquid crystals under certain conditions.

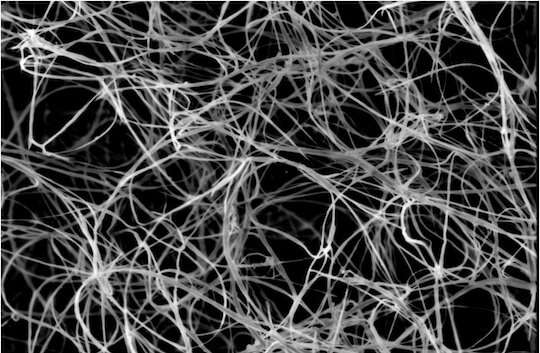

The liquid crystals are made from aligned BNNTs that are much easier to process than the tangled nanotubes that are usually found in solution. The lab created fibers and films from the solutions.

The fibers produced in Pasquali's lab are attractive for the manufacture of a variety of products, with applications that range from Wearables toAerospace Vehicles.

Carbon nanotubes have alternating carbon and nitrogen atoms in their hexagonal lattices. The strength of both types of nanotubes is not as strong as that of carbon nanotubes, but they are both good conductors of electricity and stable in the air up to 900 degrees Celsius.

To make liquid crystals, the researchers needed to make sure their nanotubes weren't contaminated. The bits of Boron nitride that were the most threatening were the ones that were most likely to gum up the works.

The lead author said that early samples contained a lot of non-nanotube boron nitride structures. They were either bound to the BNNTs or physically stuck to them, which prevented them from being dispersed in acid.

It is difficult to separate the allotropes from each other. All of the different types of boron nitride look the same.

He said that working with their supplier and using a purification process developed in the Pasquali lab helped them get better batches of BN NTs. The first boron nitride threads were made using the wet-spinning techniques of the Pasquali group.

Ginestra said that there were reports of others taking solid puffs of BNNTs and stretching and twisting them to make a yarn. The properties are better along the length of the nanotubes, so we wanted to make a very highly aligned fiber.

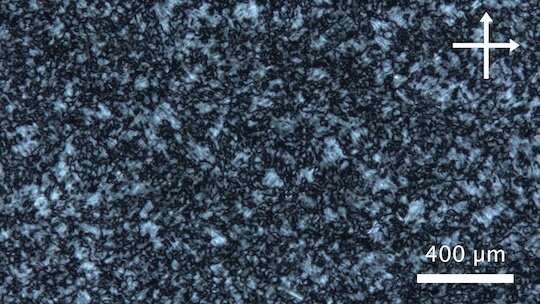

He said that liquid crystals are the best way to make fibers. Birefringence is a phenomenon in which liquid crystals split light into different colors, even if they are clear.

The films showed how carbon nanotubes can be used in solution processing. It could be useful in next- generation electronics. He said that the film and fiber properties will improve as the material improves.

The films would be useful as filters for the sun.

More information: Cedric J. Simonsen Ginestra et al, Liquid crystals of neat boron nitride nanotubes and their assembly into ordered macroscopic materials, Nature Communications (2022). DOI: 10.1038/s41467-022-30378-5 Journal information: Nature Communications