Our modern devices need a lot of energy to function. Information technology is expected to consume 25% of all primary energy by the year 2030. Microelectronics and materials sciences researchers are looking for ways to manage the need for computing power.

Efforts to move beyond today's state-of-the-art CMOS (complementary metal-oxide Semiconductor) devices is a primary goal of the effort to reduce this digital demand.

Non-Silicon materials with attractive properties for memory and logic devices exist, but they are incompatible with modern electronics due to the large voltages needed to manipulate them. It's difficult to design thin-film alternatives that can be packed into microelectronic devices.

A group of researchers at Berkeley Lab and UC Berkeley have found a way to make a thin-layer version of a well-known material that is energy efficient.

More than 80 years ago, the first discoveries of barium titanate (BaTiO 3 ) were made.

Crystals of the material respond quickly to a small electric field, flip-flops of the orientation of the charged atoms that make up the material, even if the applied field is removed. It's possible to switch between the "0" and the "1" states in logic and memory storage devices, but only if the voltages are larger than 1,000mV.

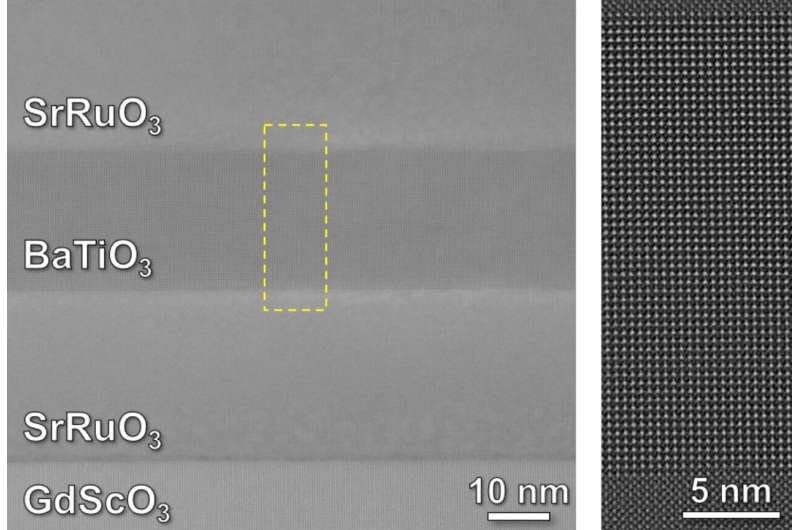

The Berkeley Lab-led team developed a pathway for creating films of BaTiO 3 just 25 nanometers thin, less than a thousandth of a human hair's width.

We know how to make thin films of BaTiO 3 for over 40 years. Lane Martin is a professor of materials science and engineering at UC Berkeley and a faculty scientist in the Materials Sciences Division at Berkeley Lab.

In the past, films with higher concentrations of "defects" have been the result of attempts to synthesise the material. Thin films are affected by a high concentration of defects. The approach to growing the films was developed by Martin and colleagues. The results were published in a journal.

The researchers used a process called pulsed-laser deposition to understand what it takes to make the best BaTiO 3 thin films. Firing a powerful beam of an ultraviolet laser light onto a ceramic target of BaTiO3 causes the material to transform into a plasma, which then transmits atoms from the target onto a surface to grow the film. Martin said that it's a versatile tool that can be used to modify knobs in the film's growth and see which knobs are most important for controlling the properties.

Martin and his colleagues were able to achieve precise control over the deposited film's structure, chemistry, thickness, and interface with metal. The researchers used tools at the National Center for Electron Microscopy at Berkeley Lab to chop each sample in half and look at its structure atom by atom.

Martin said that it was fun to think that we could take classic materials and make new approaches to making them.

Martin and his team put a film of BaTiO 3 in between two metal layers to create tiny Capacitors. The film's polarization could be switched within two billionths of a second, which is1-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-65561-6556

The bigger goal of the work is to create materials with small switching voltages and examine how metal components impact such materials. Martin said that this is a good early victory in the pursuit of low-power electronics that go beyond what is possible with Silicon-based electronics today.

Capacitors used in chips today don't hold data unless you keep applying a voltage. Current technologies can work at 500 to 600 mV, while a thin film version can work at 50 to 100 mV. Thin materials tend to be a trade-off when it comes to the tradeoff of robustness and voltage.

The team will shrink the material down even thinner to make it compatible with real devices in computers and study how it behaves at those tiny dimensions. They will work with companies like Intel to test the feasibility of first- generation electronic devices. Think how much energy you save if you made each logic operation in a computer a million times more efficient. That's the reason we're doing this.

More information: Y. Jiang et al, Enabling ultra-low-voltage switching in BaTiO3, Nature Materials (2022). DOI: 10.1038/s41563-022-01266-6 Journal information: Nature Materials