Olga Ozhogina is a journalist and a photographer. She contributed an article to Space.com's Expert Voices: Op-Ed & Insights via the press center at ProminAerospace.

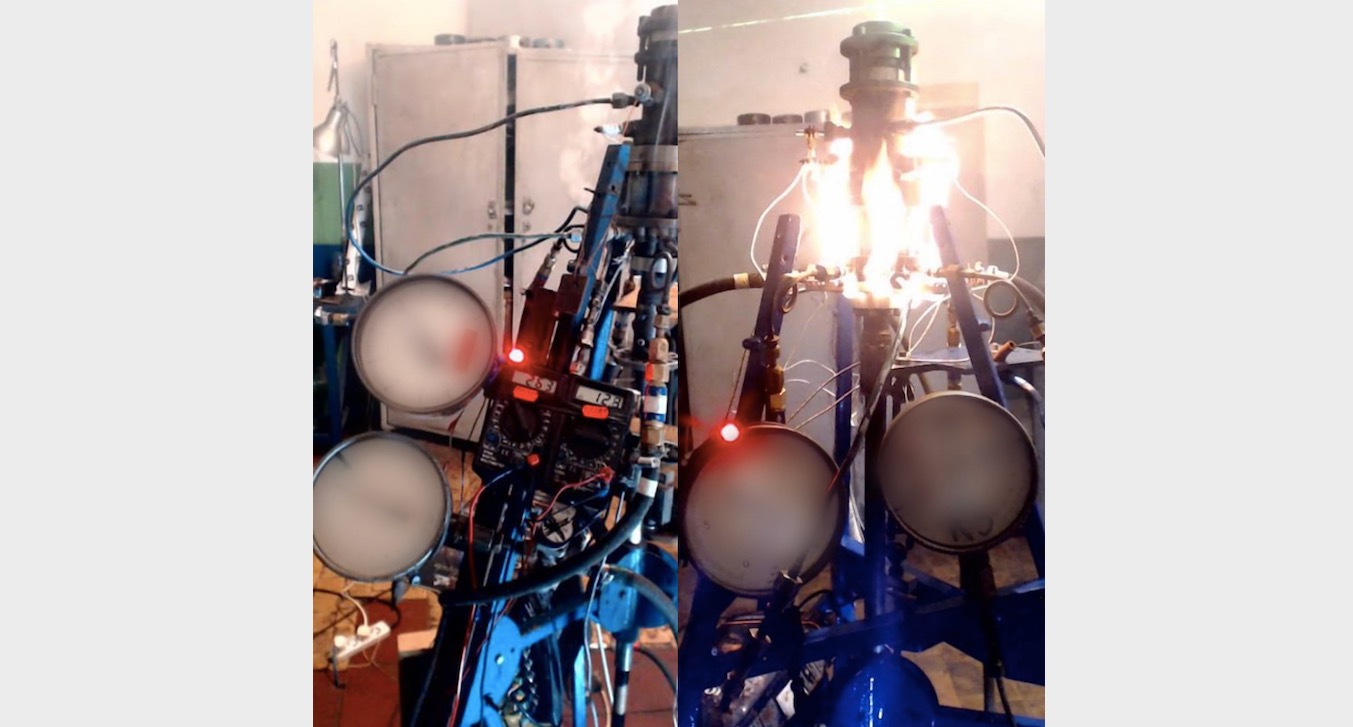

A new series of studies has been conducted on Promin's unique engine. The feasibility of the technical concept was shown in the initial tests. Engineers are experimenting with different variations of the engine assembly in order to improve the design.

Promin's chief technical officer Vitaliy Yemets originally proposed the idea of the rocket.

Ukrainian startup Promin is testing an engine for a rocket.

Solid rocket fuel would be used in an autophagic rocket, along with other propellants. The hull material needs to be strong enough and strong enough to burn. The body is eaten during the rocket's flight, allowing for a reduction in mass as it travels and leaving no debris after the flight is over. It would allow more efficient launches.

Three experiments were conducted with different variations of the engine and nozzle design, which allowed Promin to identify and investigate challenges, as well as to improve the overall performance of the assembly. All tests had to be designed from the ground up by the engineering team.

It was possible to improve the fuel supply system with the help of the initial three tests. The necessary parameters were recorded.

The engineering team used the same oxidizer that was used in the third experiment to keep the variables consistent in the fourth experiment. Engineers used a gas-oxygen mix for a starter. They used multiple temperature probes to keep an eye on the temperature in the engine areas and the pressure gauge in the pneumatic cylinder.

The firing parameters were recorded while the propellant rod was fed into the gasifier. The starting fuel and fuel assembly feeding systems were shown to work reliably, no issues with achieving combustion were recorded, and the experiment's starting component provided a higher pressure than before.

A pressure of 4 atmospheres was recorded as the starting fuel was supplied. Between 9 and 9.5 atm the fuel supply pressure was stable and the starting fuel was turned off.

The feed rate was 10mm/s and the pressure was 12 atm. The experiment was stable for 252.95 seconds, at a rate of 10mm/s and 12 atm.

The experiment lasted four minutes and forty seconds. The assembly's movement was terminated at 252.95 seconds after a flare exited the feed path. The experiment results show that no damage was done to the engine or mount truss, although some minor changes need to be made. The assembly inlet seal was improved.

The system worked well and provided enough pressure. The pressure of components in the operating mode was higher. Experiments have allowed the further development of an efficient and safe idea.

There is a history of rockets.

The engineering team used another type of fuel and oxidizer but kept the bell-shaped nozzle. The test was done the same way as before, with the starting mix being supplied under a pressure of 4 atm and turned off at 204 seconds, with the new primary fuel supplied under a pressure of 9 atm.

After the starter fuel was turned off, the pressure in the combustion chamber dropped and the temperature in the engine reached operational level. The fuel assembly stopped after the pressure on the scale went off. The increase in pressure was caused by a block in the nozzle as the gasifier's case was torn off.

The starting fuel assembly was found to work reliably despite this. There was a correlation between the feed rate of the working components and the pressure in the chamber.

The sixth experiment was conducted under a pressure of 4 atm and was turned off after three minutes and eight seconds. The fuel was supplied under a pressure of 25 atm. When a flare went off at the fuel assembly supply unit at the bottom of the combustion chamber, the pressure in the chamber stayed at 8.5 atm.

The steel turned white when the chamber overheated. It reached a temperature of around 1,000 degrees Celsius. This fuel assembly had a maximum value of 14mm/s. The experiment took five minutes and fifty seconds.

The experiment passed with pressure within limits and no explosions, proving the reliability of the construction.

The main fuel component was efficient and safe because there was no critical increase in pressure. This variant will be considered by us. The assembly inlet seal will be tightened after that test.

The oxidizer will be tested in the next experiment. It is predicted to increase the efficiency of the engine.

Promin will conduct the first test launch of its suborbital rocket after making final tests. The company will conduct launches in the future.

Vitaliy Yemets established Promin in the year 2021. The company proved the capabilities of autophagic technology and closed its first investment round.

We encourage you to follow us on social media: