A research group has discovered a biomaterial that mimics the flexibility of human bones and has excellent wear resistance. The new biomaterial could be used to make implants that don't have problems with conventional materials.

Their research was published in the journal Advanced Materials.

With the elderly population increasing across the globe, the need for improved biomaterials that can replace or support damaged bones has risen. The strength and ductility of metals make them popular for this purpose. Their flexibility decreases as a result of their strength.

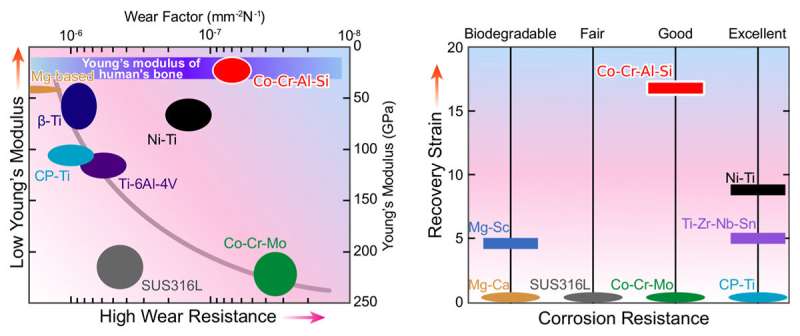

A condition called bone atrophy is caused by a breakdown in bone substance and structure when using metallic biomaterials as implants. biomaterials with elevated flexibility lose their wear resistance.

Superelastic materials made from nickel-titanium (Ni-Ti) alloys, which are commonly used in stents and orthodontist wires, have high flexibility and the ability to recover from strain, but Ni is an allergic element. Ni-free alloys are impractical because they don't duplicate the superelasticity of Ni-Ti.

The research group consisted of researchers from Tohoku University, the J-PARC Center, the Japan Atomic Energy Agency, and the Czech Academy of Sciences. A material with a low Young's modulus is flexible. It has a high Young's modulus when it is stiff.

Xiao Xu is the corresponding author and assistant professor at Tohoku University's Graduate School of Engineering.

The group of people prepared large single crystals using a heat treatment technique. The strain recovery rate for the Co-Cr-Al-Si (CCAS) alloy was twice that of commercial Ti-Ni shape memory alloys. The Young's modulus was very low, like the flexibility of human bones.

The superelasticity, flexibility, and significant wear resistance of the cobalt-chromium-based material surprised us.

The research group hopes to find out why the CCAS achieved superior properties. It could lead to the development of even better materials.

More information: Takumi Odaira et al, Flexible and Tough Superelastic Co‐Cr Alloys for Biomedical Applications, Advanced Materials (2022). DOI: 10.1002/adma.202202305 Journal information: Advanced Materials Citation: New flexible and tough superelastic metal alloy shows promise in biomedical applications (2022, May 30) retrieved 30 May 2022 from https://phys.org/news/2022-05-flexible-tough-superelastic-metal-alloy.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.