The world loses about 10 million hectares of forest each year because of forest destruction. The world's forests could disappear in 100 to 200 years, according to some scientists.

In an effort to provide an eco-friendly and low-waste alternative, researchers at MIT have invented a method to make wood-like plant material in a lab, which could be used to grow a wooden product like a table.

By adjusting certain chemicals used during the growth process, these researchers can control the physical and mechanical properties of the plant material.

They show that using 3D bioprinting techniques, they can grow plant material in shapes, sizes, and forms that are not found in nature and that can be easily produced using traditional agricultural methods.

The idea is that you can grow these plant materials in exactly the shape that you need, so you don't need to do subtractive manufacturing after the fact, which reduces the amount of energy and waste. There is a lot of potential to expand this and grow three-dimensional structures.

This research shows that lab-grown plant materials can be tailored to have specific characteristics, which could someday enable researchers to grow wood products with the exact features needed for a particular application, like high strength to support the walls of a house.

Jeffrey Borenstein is a group leader at the Charles Stark Draper Laboratory. The research is in Materials Today.

The cells are being planted.

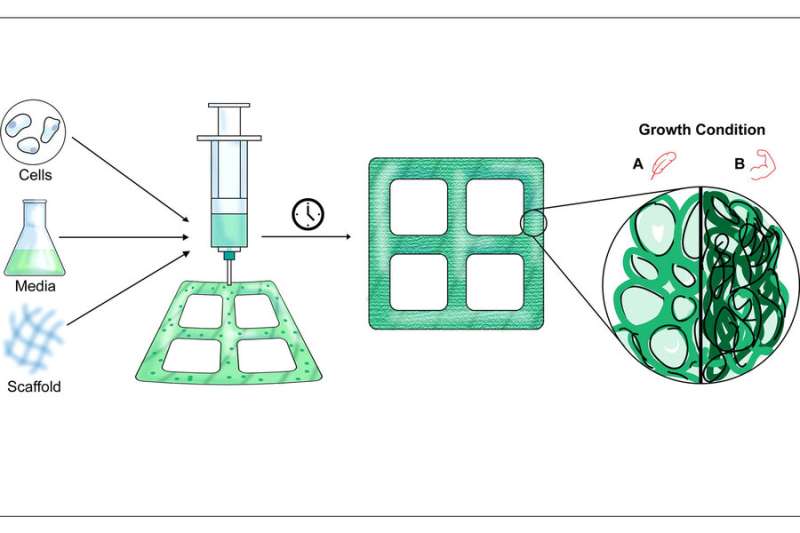

To begin the process of growing plant material in the lab, the researchers first isolated cells from the leaves of young plants. The cells are cultured in a liquid medium for two days and then transferred to a gel-based medium with different hormones.

The researchers can tune the physical and mechanical properties of the plant cells that grow in that nutrient-rich broth by adjusting the hormone levels at this stage.

In the human body, hormones determine how your cells develop and how you look. The plant cells respond differently to different concentrations of hormones. Beckwith says that by manipulating these tiny chemical quantities, we can change the physical outcomes.

These growing plant cells behave like stem cells in that they can be given instructions to become something.

They use a 3D printer to extrude the cell culture gel solution into a specific structure in a petri dish, and then let it sit in the dark for three months. The researchers process is two orders of magnitude faster than the time it takes for a tree to grow to maturity.

The researchers evaluate the properties of the dehydrated cell-based material.

The characteristics are similar to wood.

They found that lower hormone levels yielded plant materials with more rounded, open cells that have lower density, while higher hormone levels led to the growth of plant materials with smaller, denser cell structures. The researchers were able to grow plant material with a storage modulus similar to that of natural woods because of higher hormone levels.

Lignification is a study of lab-grown plant materials. Lignin is deposited in the cell walls of plants and makes them rigid and woody. They found that higher hormone levels in the growth medium cause more lignification, which leads to plant material with more wood-like properties.

The 3D bioprinting process can be used to create custom shapes and sizes for the plant material. Rather than using a mold, the process involves the use of a computer-aided design file that is fed to a 3D bioprinter, which deposits the cell gel culture into a specific shape. They were able to grow plant material in the shape of a tree.

Borenstein says that research of this kind is new.

This work demonstrates the power that a technology at the interface between engineering and biology can bring to bear on an environmental challenge.

The researchers show that the cell cultures can grow for months after printing, and that using a thicker gel to make thicker plant material does not affect the survival rate of the lab-grown cells.

It is Amenable to customization.

The real opportunity here is to use what you have and how you use it. There are expectations to consider if you want to create an object that serves a purpose. This process is very easy to modify.

The researchers want to continue experimenting so they can better understand and control cellular development after they demonstrated the effectiveness of this technique. They want to find out how chemical and genetic factors can affect the growth of the cells.

They want to see how their method could be transferred to a new species. If this method were used to make a commercially important tree species, like pine, the process would need to be tailored to that species.

He hopes that this work will encourage other groups to look into this area of research in order to reduce the amount of forest destruction.

Being as strategic as we can with the resources of trees and forests will be a societal necessity going forward.

More information: Ashley L. Beckwith et al, Physical, mechanical, and microstructural characterization of novel, 3D-printed, tunable, lab-grown plant materials generated from Zinnia elegans cell cultures, Materials Today (2022). DOI: 10.1016/j.mattod.2022.02.012 Journal information: Materials TodayThe story was re-posted by MIT News, a popular site that covers news about MIT research, innovation and teaching.

Citation: Toward customizable timber, grown in a lab (2022, May 25) retrieved 26 May 2022 from https://phys.org/news/2022-05-customizable-timber-grown-lab.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.