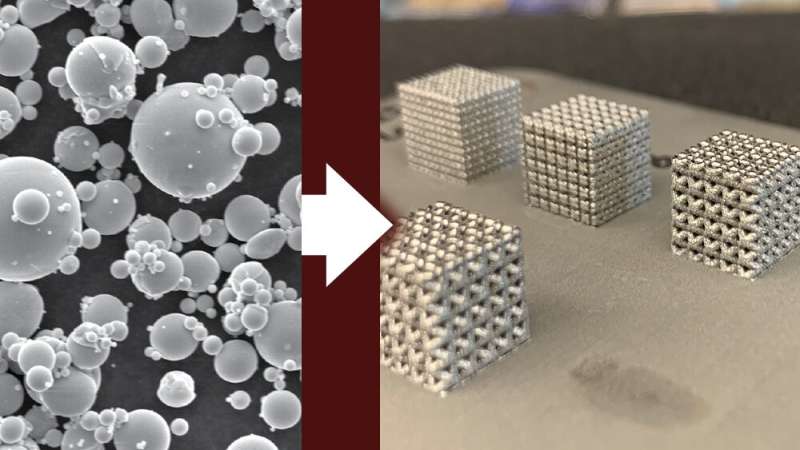

Laser powder bed fusion, a 3D-printing technique, can be used to make nickel-titanium shape memory alloys. Although this manufacturing technique is attractive for applications in the medical field, it has not shown the superelasticity required for specific applications using nickel-titanium shape memory alloys. The superelasticity was prevented from appearing in 3D-printed nickel-titanium by defects generated and changes imposed onto the material.

Researchers from Texas A&M University used laser powder bed fusion to create a shape memory alloy that was nearly double the maximum superelasticity reported in literature for 3D printing.

The study was recently published. The journal was published by the Acta Materialia.

The ability to return to their original shape upon heating or removal of applied stress is one of the reasons nickel-titanium shape memory alloys are used. They can be used in a number of fields. To develop and fabricate these materials requires extensive research to understand their functional properties.

The first author of the publication was a former PhD student in the Department of Materials Science and Engineering.

Laser powder bed fusion is a method of manufacturing nickel-titanium shape memory alloys that can be used for quick manufacturing or prototyping. This technique is similar to 3D printing and uses a laser to make metal or alloy powders. The layer-by-layer process can create parts that are impossible in traditional manufacturing.

Using a 3D printer, we spread the alloy powder over a substrate and then use the laser to melt the powder, forming one full layer.

The current laser powder bed fusion process can cause printing defects such as porosity, warping or delamination due to large thermal gradient and brittleness from oxidation. The laser can change the composition of the material.

The researchers used a framework they created in a previous study to determine optimal process parameters to achieve defect-free structure and specific material properties.

The researchers fabricated nickel-titanium parts that consistently exhibited a room temperature superelasticity of 6% in the as-printed condition without post-fabrication heat treatment. The amount of superelasticity seen in literature for 3D printing is nearly double.

3D printing with increased superelasticity means that the materials are more capable of handling applied deformation. The cost and time of manufacturing will be reduced if 3D printing is used to develop these superior materials.

The researchers hope that their discoveries will lead to increased use of printed nickel-titanium shape memory alloys.

The study can serve as a guide on how to print nickel-titanium shape memory alloys with desired mechanical and functional characteristics.

The research was funded by a number of organizations, including the U.S. Army Research Laboratory, the National Priorities Research Program grant, the Qatar National Research Fund and the U.S. National Science Foundation grant.

The materials science and engineering department head is one of the contributors.

More information: L. Xue et al, Laser Powder Bed Fusion of Defect-Free NiTi Shape Memory Alloy Parts with Superior Tensile Superelasticity, Acta Materialia (2022). DOI: 10.1016/j.actamat.2022.117781 Journal information: Acta Materialia Citation: Researchers develop 3D-printed shape memory alloy with superior superelasticity (2022, May 13) retrieved 13 May 2022 from https://phys.org/news/2022-05-3d-printed-memory-alloy-superior-superelasticity.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.