The new machine-learning framework developed by the Chemists at the U.S. Department of Energy can zero in on which steps of a multistep chemical conversion should be changed to improve productivity. The approach could help guide the design of catalysts.

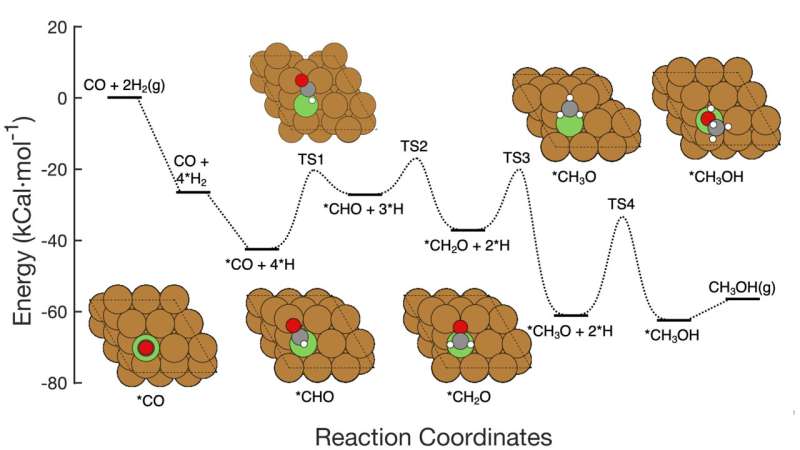

The method to analyze the conversion of carbon monoxide to methanol was developed by the team. The reaction consists of seven steps.

The first author on a paper describing the method just published in the journal Catalysis Science and Technology said that their goal was to identify which elementary step in the reaction network or which subset of steps controls the catalytic activity. Liao is a graduate student at the University who is working with scientists in the Catalysis Reactivity and Structure (CRS) group at the Lab.

The chemist who led the work said that they used the reaction as an example of the framework.

Targeting activated energy.

Imagine a chemical reaction with hills of different heights. The energy needed to get from one step to the next is represented by the height of each hill. Catalysts make it easier for reactants to come together or allow them to do so at lower temperatures or pressures. To speed up the reaction, a catalyst must target the steps that have the biggest impact.

Scientists would calculate how changing each barrier at a time might affect the production rate if they were trying to improve the reaction. This type of analysis could identify which step was rate-limiting and which step determines reaction selectivity, which is whether the reactants proceed to the desired product or down an alternate pathway.

The estimations end up being very rough with a lot of errors for some groups of catalysts. That has hurt catalyst design and screening, which is what we are trying to do.

Scientists can better predict how catalysts will affect reaction mechanisms and chemical output with the new machine learning framework.

We are moving all the barriers at the same time. Liao said that they use machine learning to interpret the data.

The team said that this approach gives more reliable results, including how steps in a reaction work together.

The steps are all connected under reaction conditions. That is what has been captured in this development.

The model is being built.

The scientists built a data set to train their machine learning model. The data set was based on density functional theory calculations of the activation energy required to transform one arrangement of atoms to the next through seven steps of the reaction. The scientists ran simulations to see what would happen if they changed all seven barriers at once.

The range of data we included was based on previous experience with these reactions and the variation that is likely to give you better performance.

The team produced a comprehensive dataset of 500 data points. The dataset predicted how the individual tweaking and pairs of tweaking would affect production. The model scored according to their importance in driving the output.

The model learned from the data and identified six key descriptors that it predicts would have the most impact on production.

The scientists retrained the model using only the six active descriptors. The model was able to predict activity based on DFT calculations.

You can calculate with only six of the 28 descriptors and get the conversion rates you are interested in.

The model can be used to screen catalysts. The model predicts a maximal production rate if they can design a catalyst that improves the value of the six active descriptors.

Understanding mechanisms.

When the team compared the predictions of their model with the experimental performance of their catalyst and the performance of various metals with copper, the predictions matched up. The previous method used to predict performance was far superior to the ML approach.

Changes in energy barriers can affect the reaction mechanism. How different steps of the reaction work together was of particular interest. The data showed that lowering the energy barrier in the rate-limiting step alone wouldn't improve the production of methanol. Keeping the rate-limiting step within an ideal range would increase the output of methanol.

The method gives us detailed information that we can use to design a catalyst that coordinates the interaction between the two steps.

The potential for applying such data-driven ML frameworks to more complicated reactions is exciting.

We used the reaction to demonstrate our method. She said that the way that it generated the database and how we trained the model can be applied to other reactions.

More information: Wenjie Liao et al, Enhanced descriptor identification and mechanism understanding for catalytic activity using a data-driven framework: revealing the importance of interactions between elementary steps, Catalysis Science & Technology (2022). DOI: 10.1039/D2CY00284A Citation: Machine learning framework IDs targets for improving catalysts (2022, May 10) retrieved 10 May 2022 from https://phys.org/news/2022-05-machine-framework-ids-catalysts.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.