NASA, the European Space Agency, China, and Roscosmos are all planning to send people to the Moon in the near future. This will be the first time astronauts have walked on the moon. The goal of these programs is not to get their first and leave only a few experiments and landers behind. This means creating habitats on the surface and in the sky.

While NASA and other space agencies intend to leverage local resources as much as possible, creating lunar bases will still require lots of materials and machinery to be shipped from Earth. The cost and energy consumption of building landing pads on the moon were reviewed by Philip and Greg. After considering various construction methods, they decided that the most efficient and cost-effective way to build was with a combination of Additive manufacturing and polymer infusion.

Philip is an associate scientist with the Florida Space Institute and a former senior research physicist at NASA. Greg Autry is a clinical professor of Space Leadership, Policy, and Business with the Thunderbird School of Global Management at Arizona State University.

They looked at different methods for building landing pads on the moon. The need to ship large amounts of mass from Earth, the level of energy consumption on the lunar surface, and the time it would take to finish construction were some of the factors that were evaluated. The overall cost of lunar activities is influenced by each of these factors.

The most important variables when evaluating in-space construction methods are transportation costs and the delays imposed by the construction process. In an email, Metzger explained to Universe Today.

“I was surprised that the complexity and reliability of the construction process did not play a larger role. A complex system will need about 50% more up-front investment to make it as reliable as the simpler methods, and a 50% cost increase sounds like a lot, but compared to the cost of lunar transportation and the loss of value if you delay doing things on the Moon, it turns out that 50% more development cost is utterly inconsequential.

“So if you invent a more complex method of doing things, and that method is faster and lower mass than previous methods, then it is worth it. That goes against our natural tendency as space technologists. We think keeping things simpler is better, and we think when we are operating far away on the Moon it is even more important to keep things simple. But when we look at it from an economic perspective, that feeling doesn’t turn out to be true. In the economic environment of lunar operations, higher technology is worth the greater up-front investment.”

They found that the thickness of the pads, the thermal environment, and the launch cadence of the lunar program were important factors in establishing practical limits on construction time. The cost per kilo of launching is the most important factor in determining the cost-effectiveness of each method. They looked at the energy requirements and how this would change depending on the thermal environment.

In particular, they considered recent innovations in 3D printing and ISRU, which have been the subject of research by NASA and the ESA for many years. These methods call for heating regolith with microwaves to create a molten ceramic that can be printed out or added to a bonding.

“Some methods require huge amounts of energy, which requires heavy energy systems on the Moon. Other methods require many tons of binder brought from Earth at great expense. Still, others are very, very slow processes. We wanted to see how these different factors compare to each other when we look at it from an economic perspective.

“We converted everything into a real cost: the cost of transporting mass from Earth; the cost of energy delivered on the Moon; the loss of economic value if we take a long time doing construction. Putting it all together we could see which construction methods provide the best value to lunar operations.”

They found that microwave sintering provided the best combination of low mass and high speed. The inner, high-temperature zone of the lunar landing pad is where the take-off and landing rocket burns happen. This method is the best for constructing the outer, low-temperature zone if transportation costs are high.

In the event that transportation costs can be kept at $110 per kilogram, the most cost-effective method would be to use the injection method. The total cost of building the Artemis Base Camp was estimated by them, as well as the surface habitat NASA intends to build around the South Pole-Aitken Basin. The transportation costs will drop from their current rate of $1 million per kilo to $300,000 per kilo. It was summarized by Metzger.

“We found that the cost of building a landing pad during NASA’s Artemis program is quite affordable — about the same cost as a NASA Discovery-class spacecraft ($300M). That is a tiny cost compared to many other elements of a human spaceflight program. For that cost, the program will create the first permanent facility constructed on another world, and it will also deliver the construction robots to the Moon, so they can begin doing other tasks like building human habitats.”

If transportation costs can be further reduced to $100,000 per kg or less, the estimates will fall to $130 million. The price tag for a lunar base will depend on the extent to which launch costs continue to decline. The number of space agencies looking to build outposts in the South Pole-Aitken Basin in this decade and the next is of particular significance.

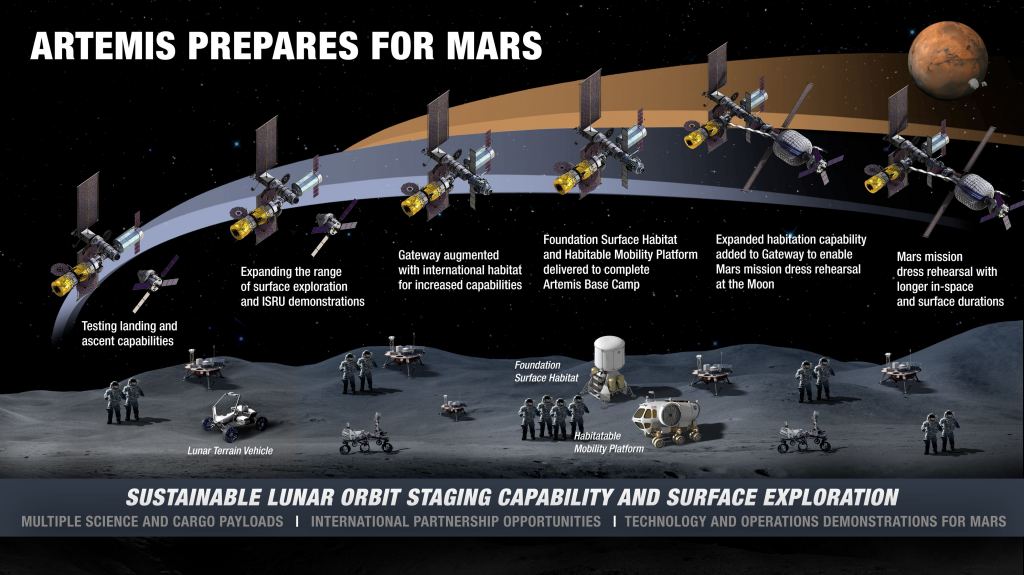

The International Moon Village will be a permanent base and will be known as the Artemis Base Camp. This base would be a spiritual successor to the International Space Station and would be able to accommodate rotating crews of astronauts, long-duration stays, and science operations on the Moon. Representatives of the Chinese and Russian space programs came together to announce a shared vision for a lunar base.

NASA and other space agencies are researching technologies that will allow for cost-effective construction on the moon. Researchers at Texas A&M University have pioneered a manufacturing process known as Regolith adaptive modification system. The process focuses on providing early-stage infrastructure that would facilitate the transportation of equipment.

The Institute for Advanced Concepts (NIAC), Honeybee Robotics, Texas A&M, and the University of Central Florida are all involved in the development of the lunar lander concept. The concept uses the in-Flight Alumina Spray Technique (FAST), where a lander injects aluminum particles into its landing nozzles to fashion its own landing pad, which mitigates the problem of lunar dust being kicked up.

Humans will return to the Moon in the next decade and a half. Multiple space agencies will be sending astronauts, but commercial partners will be enlisted to provide transportation services. A permanent human presence and the first generation of loots may eventually follow, as lunar tourists and even settlers follow.

This multinational effort is fostering innovation across multiple sectors and leading to applications for life here on Earth. If we are going to ensure that humans can live in space, we need to be inventive.

Further reading: arXiv