The inspiration for a new lightweight, 3D printed smart architected material was derived from the cellular forms of natural materials.

The team, led by engineers from the University of Glasgow, mixed a common form of industrial plastic with carbon nanotubes to create a material which is tougher, stronger and smarter than comparable conventional materials.

The plastic can carry an electric charge throughout its structure thanks to the nanotubes. The structure's electrical resistance changes when it is subjected to mechanical loads. This phenomenon gives the material the ability to sense its structural health.

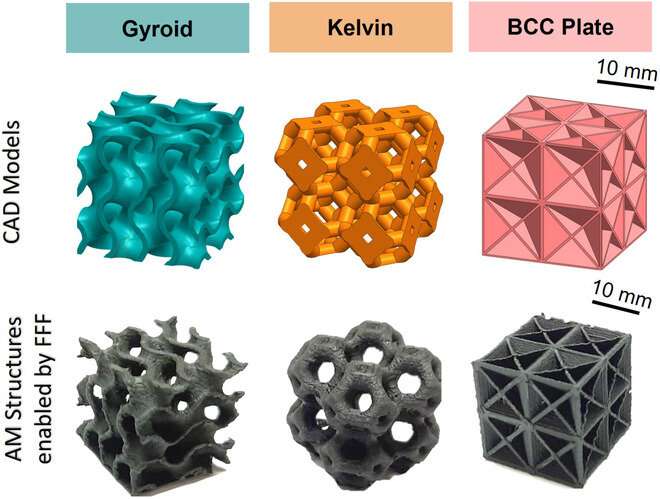

By using advanced 3D printing techniques that provide a high level of control over the design of printed structures, they were able to create a series of intricate designs with mesoscale porous architecture, which helps to reduce each design's overall weight and maximize mechanical performance.

The team's designs are similar to porous materials found in the natural world, like sponges and bone, which are lightweight but robust.

The researchers believe that their cellular materials could be used in new applications in medicine, prosthetics and automobile design, where low-density, tough materials with the ability too self-sense are in demand.

The paper can be found online in the journal Advanced Engineering Materials.

In the paper, the researchers describe how they used their custom material, which is made from random co-polymer and multi-wall carbon nanotubes, to create three different designs.

They found that the cube-shaped plate-lattice was the most effective mix of mechanical performance and self-sensing ability.

When subjected to monotonic compression, the lattice structure shows an energy absorption capacity similar to nickel foams. It was better than a number of other conventional materials.

The research was led by Dr. Kumar from the University of Glasgow, along with professors from the University of Cambridge and the Massachusetts Institute of Technology.

Nature has a lot to teach engineers about how to balance properties and structure to create high performance lightweight materials. We took inspiration from these forms to develop our new cellular materials, which offer unique advantages over their conventionally produced counterparts and can be finely tailored to manipulate their physical properties.

The random co-polymer we chose offers enhanced processability, improved temperature resistance, better product consistency, and better impact strength. The carbon nanotubes help to make it strong. We can choose the extent of porosity in the design to enhance the mechanical properties.

These materials have a lot of potential for practical applications. They could help make lighter, more efficient car bodies, or back braces for people with issues like Scoliosis, which can be detected when their bodies are not receiving optimal support. They could be used to create new forms of architected electrodes.

The team's paper is published in Advanced Engineering Materials.

More information: Jabir Ubaid et al, Multifunctionality of Nanoengineered Self‐Sensing Lattices Enabled by Additive Manufacturing, Advanced Engineering Materials (2022). DOI: 10.1002/adem.202200194 Citation: Nature-inspired self-sensing materials could lead to new developments in engineering (2022, May 10) retrieved 10 May 2022 from https://phys.org/news/2022-05-nature-inspired-self-sensing-materials.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.