A class of chemicals used as building blocks in products ranging from pharmaceuticals and agrochemicals to detergents and organic light emitting diodes has been developed by researchers at North Carolina State University.

The new technique for producing amines is complicated and expensive, but it is the only one that can be used in a wide range of products.

HAM is one of the less expensive ways to make hindered amines. The chemical industry has largely avoided using HAM because there are too many ways things can go wrong. Over the years, researchers have improved the HAM process. The HAM process takes hours to perform all of the necessary reactions because of the extended timeframe. Until now.

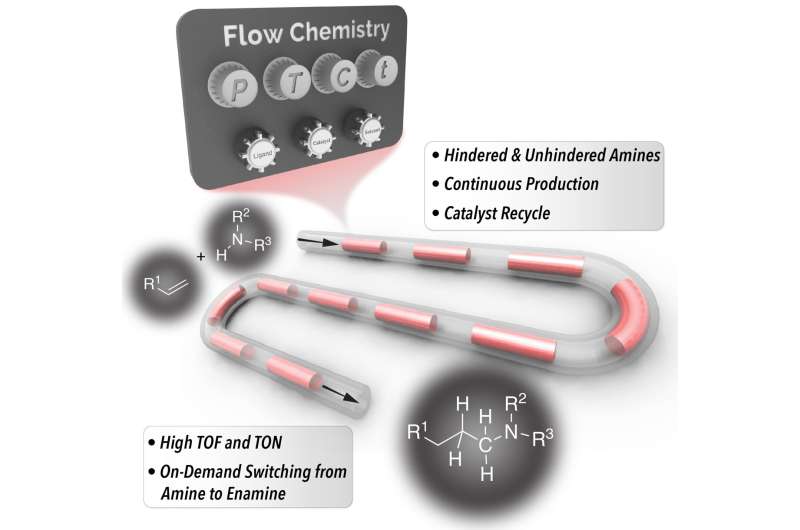

The HAM process takes less than 30 minutes in most cases. Water and amine are the only products that are hindered. We are able to recycle the primary catalyst, rhodium/N-Xantphos, which further drives down costs.

There are two things that make the success of the new technique possible. The researchers were able to make the reaction far more efficient by using a continuous flow reactor that allows for continuous flow of both gases and liquids. The new technique reduces the amount of energy needed to perform some of the necessary reactions in the HAM process.

This technique drives down the cost of producing amines by using inexpensive feedstock, which will allow users to produce them more quickly and with no toxic byproducts.

The rate of the HAM reactions in our system can be 70 times higher than the existing state-of-the-art processes.

The small footprint of the necessary equipment and the fact that users can easily produce amines on site and on demand make the new technique attractive for decentralized manufacturing operations.

Enamines, which are other chemical building blocks, can be produced by tuning the solvent we use in the flow reactor.

The researchers have filed a patent for the new technique and are looking for industrial partners to use it.

The paper will be published in the journal Nature Communications on May 4.

More information: Recyclable Cooperative Catalyst for Accelerated Hydroaminomethylation of Hindered Amines in a Continuous Segmented Flow Reactor, Nature Communications (2022). DOI: 10.1038/s41467-022-30175-0 Journal information: Nature Communications Citation: Researchers devise cheaper, faster way to continuously produce amines (2022, May 4) retrieved 4 May 2022 from https://phys.org/news/2022-05-cheaper-faster-amines.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.