N95 face masks can be made with an accessible way to make them. The masks don't need to be replaced as often, which can cause less plastic waste.

Helen Zha, assistant professor of chemical and biological engineering, and Edmund Palermo, associate professor of materials science and engineering, collaborated on a project.

Palermo said that the challenge was a multi-material engineering challenge. The work is the first step in the process of self-sterilizing personal protective equipment. It might help reduce the transmission of airborne pathogens.

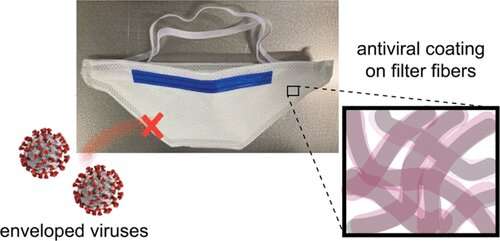

The team succeeded in attaching broad-spectrum antimicrobial polymers to the filters used in the N95 face mask.

The N95 masks are very sensitive to chemical modification. They no longer perform like N95s because of it. It's hard to modify them because they're made out of polypropylene. One challenge is that you don't want to disrupt the very fine network of fibers in these masks, which could make them more difficult to breathe through.

Zha and Palermo are part of a group of researchers from Massachusetts Institute of Technology, Michigan Technological Institute, and other institutions. The fabrics were given to us by a friend.

Zha said that the process that they developed uses a simple chemistry to create a non-leaching coating that can kill Viruses andbacteria. It's simple andScalable

To make it easy to implement, the team used only UV light and acetone. It is possible to apply the process to already manufactured filters rather than developing new ones.

When the process was applied directly to the N95 masks, there was a decrease in the efficiency of the filters. The user could wear an unaltered N95 mask along with a second layer of polypropylene. The top layer of a mask could be made with the antimicrobial polymers.

Zha and Palermo started their research in 2020 when there was a shortage of face masks.

The masks were supposed to be used only for single use. Face masks of all types are available now. The threat of another Pandemic in the future is a distinct possibility, and disposable masks are piling up in the garbage.

Zha hopes that we are on the other side of the COVID epidemic. This type of technology will be important in the future. There is still a risk of diseases caused by airborne microbes. We need to improve the performance of the materials that we use to protect ourselves.

Shekhar Garde is the Dean of the School of Engineering at Rensselaer. It's possible that this strategy is useful in many other contexts.

More information: Mirco Sorci et al, Virucidal N95 Respirator Face Masks via Ultrathin Surface-Grafted Quaternary Ammonium Polymer Coatings, ACS Applied Materials & Interfaces (2022). DOI: 10.1021/acsami.2c04165 Journal information: ACS Applied Materials and Interfaces