According to a Penn State led team of scientists, an innovative new strategy for creating fiber actuators could lead to the creation of smart clothing.

"Actuators are any material that will change under any external stimuli, like parts of a machine that will contract, bend or expand," said Robert Hickey, assistant professor of materials science and engineering. Soft, lightweight versions of these materials that can act as artificial muscles need to be developed. We are trying to find a new way to do this.

The team developed a two-step process to make fiber actuators that mimic the structure of muscle fibers and that excel in a number of aspects compared to other current actuators. They published their findings in the journal.

There's a lot of exciting research out there, but the focus has been on engineering materials to maximize properties. chemistry, structure and property are connected in our work.

The team that led the creation of self-assembling, nanomaterials was led by Hickey. Large amounts of water can be held in networks of hydrogels.

The scientists found that the fibers made of this material can stretch several times their original length when hydrated and hardened, and then dried in a shape that is longer than their original length. The scientists said that adding water or heat would allow the material to snap back to its original size.

The fibers were showing some really interesting properties. We realized that there was some really interesting stuff going on when we began to understand the structure. We began to recognize that the structure of these mimicked natural muscles.

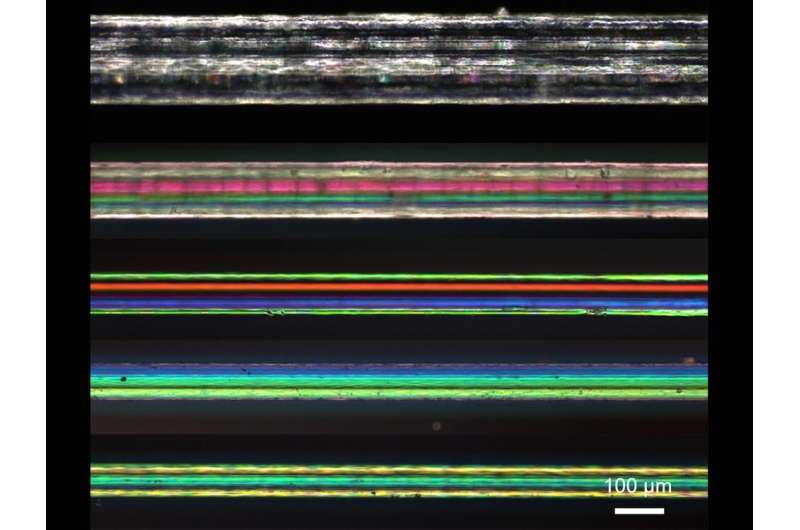

Scientists said the materials are similar to the ordered and striated pattern of mammals.

The stretching properties of the hydrogels are a result of the combination of a rigid amorphous nanoscale domain and a small scale pores filled with water. The hydrogels snap back when they're stretched. The stretched fibers will lock in the shape of the fibers if they are dried in extended states.

The sarcomere of a human muscle is one of the reasons we have these exceptional properties. You have a contraction. The ability to come back to that original state is due to the fact that the domains are all in a single direction.

The material can return to its original form if water or heat is applied to it. The scientists said that when stretched to five times its original length, the material can return to 80% of its size in a single cycle.

Double the possibilities for materials made with this method are opened up by the fact that we can use two different stimuli, heat and water. The majority of actuator are triggered by a single event. There are two stimuli that open up theVersatility of our Materials.

More information: Chao Lang et al, Nanostructured block copolymer muscles, Nature Nanotechnology (2022). DOI: 10.1038/s41565-022-01133-0